A Comprehensive Guide to Lead Sheet Manufacturing and Applications | Shandong Qite

A Comprehensive Guide to Lead Sheet Manufacturing and Applications | Shandong Qite

Lead sheet, as an important industrial and protective material, plays an irreplaceable role in numerous critical areas with its high density, corrosion resistance, and excellent radiation shielding properties. Shandong Qite Radiation Protection Engineering Co., Ltd. takes you on an in-depth exploration of lead sheet's precision manufacturing process and its wide range of applications, fully understanding the exceptional value of this material.

1. Precision Lead Sheet Manufacturing Process

Lead sheet manufacturing primarily relies on two established processes: casting and rolling, which together ensure high quality and high performance.

Casting: The Foundation for Customization

Raw Material Preparation: Strictly select high-purity lead to ensure product quality from the source.

Smelting: The lead is heated to above 327.5°C in a furnace to melt into a liquid state, with continuous stirring to ensure uniform composition.

Casting: The molten lead is precisely poured into a specific mold, precisely controlling the speed and pressure to avoid air bubbles and inclusions, and then formed into the desired shape and size.

Cooling and Processing: After natural cooling and solidification, the product is demolded and then subjected to finishing processes such as cutting and polishing to meet individual customer needs. This method is particularly suitable for producing lead sheets with larger thicknesses or unique shapes.

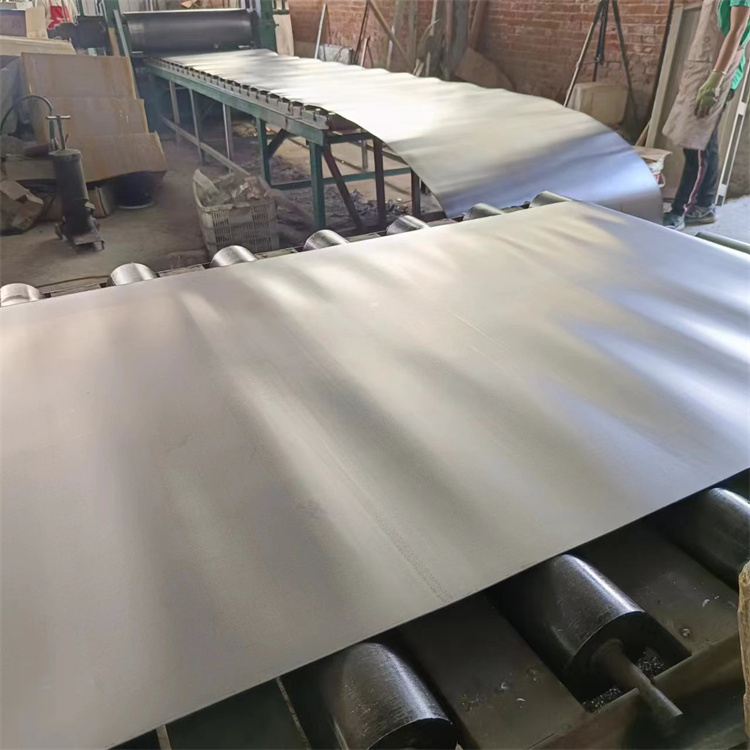

Rolling: Produces uniform and efficient sheet materials.

Raw Material Preparation: Select high-quality lead ingots to ensure material purity.

Heating: Soften the lead ingots by heating to facilitate subsequent processing.

Rolling: Apply pressure through a rolling mill, gradually rolling the ingots into sheets with uniform thickness and a smooth surface through multiple rolling passes.

Annealing and Surface Treatment: After rolling, annealing is performed to eliminate internal stresses and improve the sheet's toughness and ductility. Finally, pickling and spraying processes enhance corrosion resistance and appearance. This method offers high production efficiency and is particularly suitable for mass production of uniformly sized lead sheets.

II. Wide Range of Lead Sheet Applications

Lead sheet's unique properties make it a shining example in the following key areas:

Medical: A Guardian of Safety

Lead sheet is an essential protective material for radiation-related departments such as hospital X-ray rooms, CT scan rooms, and DR rooms. It effectively blocks X-rays and gamma rays, ensuring the safety of medical staff and patients. Its excellent soundproofing properties also make it suitable for use in environments requiring a quiet environment, such as operating rooms.

Industrial and Nuclear Energy: A Core Barrier of Protection

In industrial flaw detection, nuclear power plants, nuclear medicine, and research institutes, lead sheet is used to construct protective shielding walls and doors, as well as radiation protective clothing, providing solid protection for workers against the hazards of radioactive substances.

Chemical Industry: Reliable, Corrosion-Resistant Equipment

Thanks to its excellent acid and alkali resistance, lead sheet is often used in the manufacture of chemical storage tanks, reactor linings, and pipelines. It effectively resists corrosion from highly corrosive media such as sulfuric acid and hydrochloric acid, ensuring production safety and long-term equipment operation.

Construction and Other Fields: Expanded Multifunctional Applications

Battery Manufacturing: As a core component of lead-acid batteries, lead sheet is used to manufacture both positive and negative plates.

Construction: It is used in waterproofing and soundproofing walls. Its excellent flexibility also makes it suitable for architectural decoration and sculpture.

Other Fields: Lead sheet also plays a key role in special equipment such as printing plate making, protective clothing, and aerospace.

Conclusion

From its precise manufacturing process to its wide-ranging applications across multiple sectors, the importance of lead sheet is undeniable. Shandong Qi Te Radiation Protection Engineering Co., Ltd., with deep industry experience, not only possesses a profound understanding of the material properties of lead sheet, but also offers comprehensive services, from material supply to customized solutions tailored to your specific application scenario (whether for medical protection, industrial safety, or specialized engineering). We are committed to ensuring the safety of your projects with our professional technology and products.