Radiation Protection Barium Sand

Radiation-proof barium sand (barium sulfate) has a high density (4.5g/cm³) and can effectively shield X/γ rays. It is environmentally friendly and non-toxic, and can replace lead to avoid pollution. It is flexible to construct (can be poured or mixed with cement for smoothing), has strong bonding force and low cost. It is corrosion-resistant, high-temperature-resistant and has a long service life. It is suitable for walls and floors in medical (CT rooms), nuclear industry, laboratories, etc. It is lightweight and reduces loads, has good stability, meets international standards, and has both safety and economy. It is the preferred material for radiation shielding projects.

Radiation-proof barium sand is a granular material made of natural barite (mainly barium sulfate, BaSO₄) through crushing, screening, purification and other processes. Due to its high density (≥4.2g/cm³) and the shielding performance of heavy metal elements (barium), it can effectively absorb ionizing radiation such as X-rays and gamma rays, and is widely used in radiation protection projects in the fields of medical, industrial and nuclear facilities.

1. Core characteristics

High-density shielding: density ≥4.2g/cm³, far exceeding ordinary concrete (2.4g/cm³), with higher shielding efficiency.

Environmentally friendly and non-toxic: natural inorganic materials, no volatiles, in line with GB/T 18883-2022 environmental protection standards.

Convenient construction: uniform particles, can be mixed with cement and mortar, and cast into radiation-proof walls or floors.

Strong durability: high temperature resistance, corrosion resistance, stable performance, and long service life.

2. Main uses

Medical field: wall/ground protection of CT room, DR room, dental X-ray room, radiotherapy room, etc.

Industrial field: shielding layer of nuclear power plant, radioactive laboratory, industrial flaw detection room.

Other scenarios: places that require radiation isolation, such as scientific research institutions and security inspection channels.

3. Technical parameters

Project Parameter index

Main component Barium sulfate (BaSO₄) ≥90%

Density ≥4.2g/cm³

Particle size 20-80 mesh (customizable)

Water content ≤0.5%

Ray absorption capacity Equivalent lead plate 2-3mm (according to thickness ratio)

Compressive strength ≥25MPa (after mixing mortar)

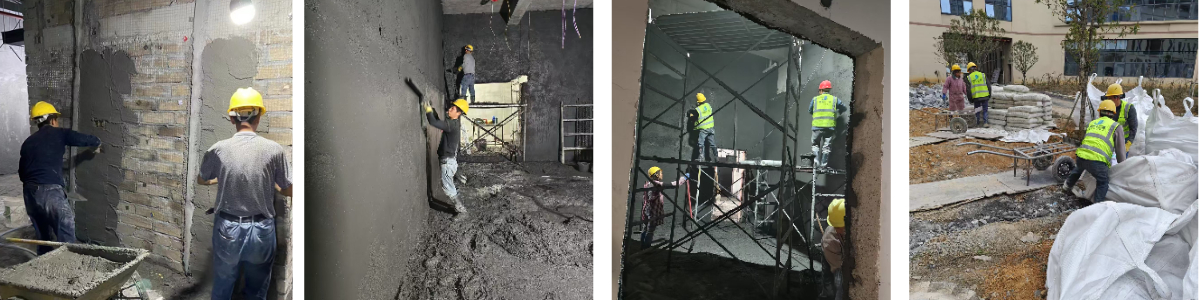

4. Construction method

Recommended ratio: barium sand: cement: water ≈ 4:1:0.5 (adjusted according to engineering design requirements).

Construction steps:

Base treatment: clean the base and keep it flat and free of cracks.

Mixing and stirring: Mix barium sand, cement and water in proportion and stir evenly.

Casting and leveling: Cast in layers (each layer ≤ 5cm), vibrate and level after compaction.

Curing: Sprinkle water and maintain at room temperature for more than 7 days.

5. Notes

Thickness design: The required shielding thickness needs to be calculated according to the radiation type (such as X-ray energy level), and it is recommended to be evaluated by a professional organization.

Anti-cracking: Expansion joints need to be reserved during large-scale construction to avoid shrinkage cracking.

Storage conditions: dry and ventilated, moisture-proof and anti-caking.

6. Packaging and specifications

Conventional packaging: 50kg/bag or ton bag (customizable).

Color: off-white or light yellow (natural mineral color).

7. Quality certification

Complies with GB/T 23456-2018 Specification for Radioactive Shielding of Protective Materials.

Provide third-party test reports (such as CMA-certified radiation shielding performance tests).

If you need more detailed technical solutions or construction guidance, please provide specific application scenarios (such as machine room area, equipment type, etc.) and we will customize a solution for you.