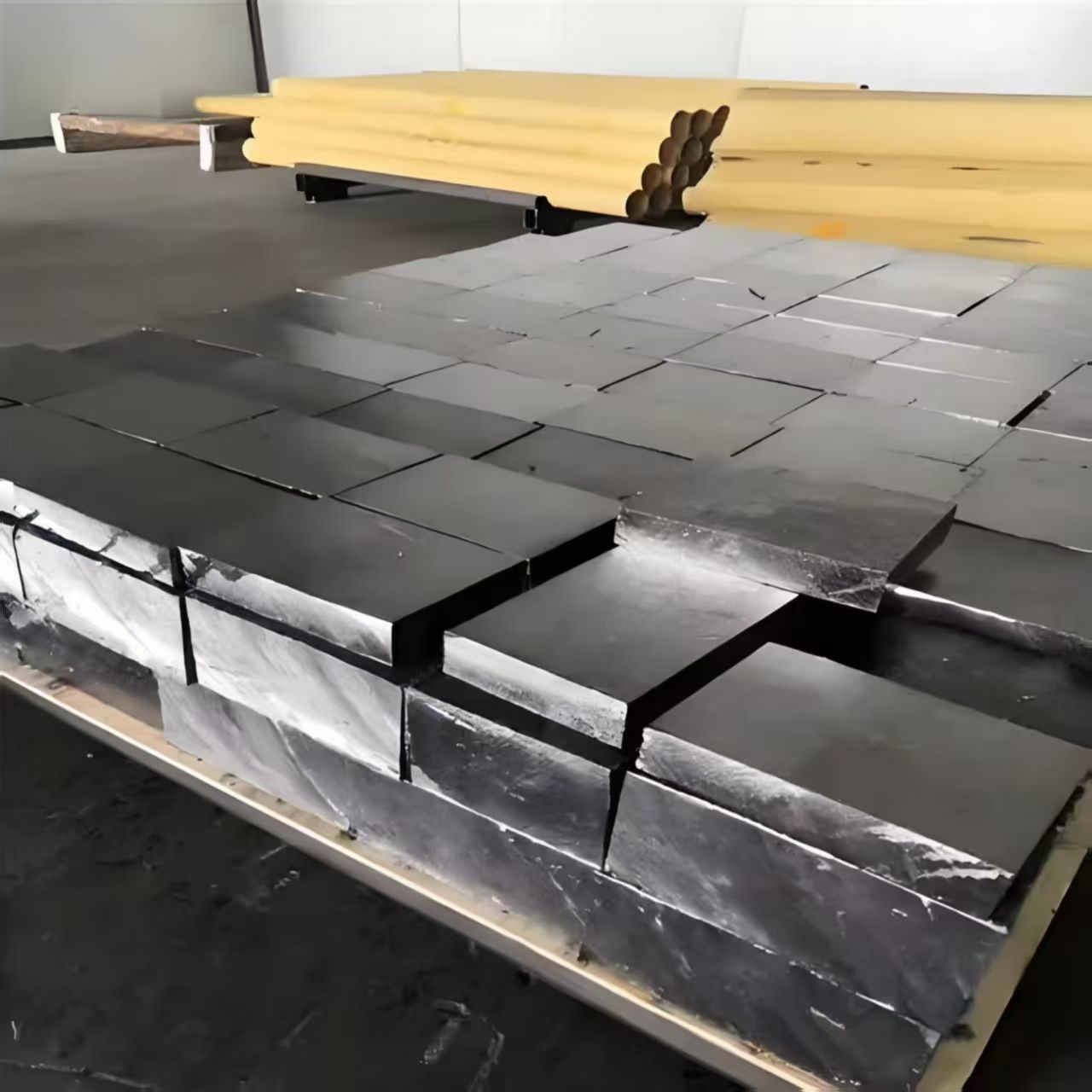

Lead Sheet Protection

Absolute protection efficiency

Density 11.34g/cm³, 1mm thickness is equivalent to 1mmPb lead, shielding rate for high-energy gamma rays>99%.

Ultra-thin and space-saving

2-3mm meets medical/industrial protection needs, saving 90% space compared to concrete walls.

Flexible and easy to shape

Can be bent to wrap pipeline equipment (radius of curvature ≥5 times thick), adapt to complex structures.

Extreme environment stability

Corrosion and aging resistance, -50℃~150℃ performance unchanged, life span>50 years.

100% circular economy

Waste lead is fully recycled and reused, and the long-term cost is lower than that of composite materials.

Lead plate protection core value

Lead plate is rolled from 99.99% high-purity electrolytic lead. With its extreme density of 11.34g/cm³ and physical properties of atomic number 82, it has become the industry gold standard for shielding high-energy X/γ rays and neutron flows. It is irreplaceable in fields such as nuclear power and medical radiotherapy that have strict requirements on space efficiency and protection level.

1. Five core advantages

Absolute shielding effectiveness

1mm thickness means 1mmPb lead equivalent protection, shielding rate of high-energy γ rays above 300kV>99%, covering the full energy spectrum of 10keV-10MeV, and performance rolling composite materials.

Revolutionary breakthrough in space

The medical CT room only needs 2mm thickness (equivalent to 1 meter concrete wall protection), saving 90% of building space, especially suitable for renovation projects.

Flexible engineering adaptability

Lead plates can be cut and welded, and lead coils can be bent and wrapped around pipeline equipment (minimum curvature radius ≥5 times the plate thickness), perfectly fitting complex structures such as curved walls and equipment.

Cross-century stability

Acid and alkali corrosion resistance (-50℃~150℃ performance unchanged), anti-aging, service life of more than 50 years, maintenance cost close to zero.

Circular economy model

100% of waste lead is recycled, smelted and reused, and the long-term cost is lower than alternative materials such as barium sulfate.

2. Core application scenarios

► Medical protection field

Radiotherapy room: 3mm lead plate is used to construct the wall/protective door, and the joints are sealed with step overlap + lead tape to shield the 6-15MV high-energy gamma rays generated by the linear accelerator.

Imaging diagnosis department: 2mm lead plate is used to make the CT machine annular protective cover, and 1.5mm lead roll covers the mobile lead screen frame to block scattered radiation.

► Key protection of nuclear industry

Nuclear waste management: 50mm composite lead plate is used as the lining of the transport container to protect the radiation of radioactive isotopes.

Reactor engineering: Lead-cadmium composite plate is used for neutron moderation layer, and the hot room observation window adopts lead glass + lead plate composite structure.

► Industrial and civil engineering

Industrial flaw detection: 5-10mm lead plates are used to construct accelerator shielding walls, and lead coils are used to wrap around pipeline weld inspection stations.

Civil protection: 0.5mm lead plates are attached to basement walls to prevent radon radiation, and data centers use lead plate ceilings to shield electromagnetic interference.

III. Technical parameters and construction specifications

Key performance parameters

Material purity: ≥99.99% (GB/T 1470-2020, medical grade ≥99.994%)

Density: 11.34g/cm³ (20℃ benchmark value)

Thickness range: rigid lead plate 1-50mm, flexible lead coil 0.5-5mm

Mechanical strength: tensile strength ≥15MPa, elongation ≥45%

Key points of professional construction

Sealing and leakage prevention

Use lead plate nails to fix the joints, cover with lead tape for double sealing

Step-by-step overlap for door and window openings (overlap width ≥100mm)

Fill the pipeline perforation area with lead casing + lead putty

Structural adaptation plan

Flat wall: light steel keel base support, staggered installation of lead plate

Curved surface/pipeline: cold press welding to fix the joints after lead coil winding

Surface protection treatment: cover with gypsum board or apply epoxy resin coating to prevent physical damage

IV. Safety warning and industry status

Mandatory safety measures

Cutting/welding operations must be equipped with a forced ventilation system, and operators must wear EN 149 certified lead dust masks and protective clothing

Waste lead plates must be handled by licensed recyclers, and landfill or incineration is strictly prohibited

Summary of irreplaceability

In the field of high-risk radiation protection such as nuclear power and radiotherapy, lead plates have built an irreplaceable safety line with their absolute shielding ability, millimeter-level space occupancy and half-century long life. The International Atomic Energy Agency (IAEA) clearly lists it as the preferred material for high-energy radiation protection, and continues to protect the border security of human nuclear energy applications and medical progress.