Professional Craftsmanship Solves the Problem of Lead Plate Gap Protection in CT Rooms

Professional Craftsmanship Solves the Problem of Lead Plate Gap Protection in CT Rooms

In the field of medical radiation protection, experts often say, "A single oversight in a gap can render the entire protection system ineffective." Especially in the renovation of high-precision imaging departments such as CT rooms, the precise treatment of gaps between lead plates is a core benchmark for measuring project quality and technical strength, directly impacting patient and medical safety and environmental protection.

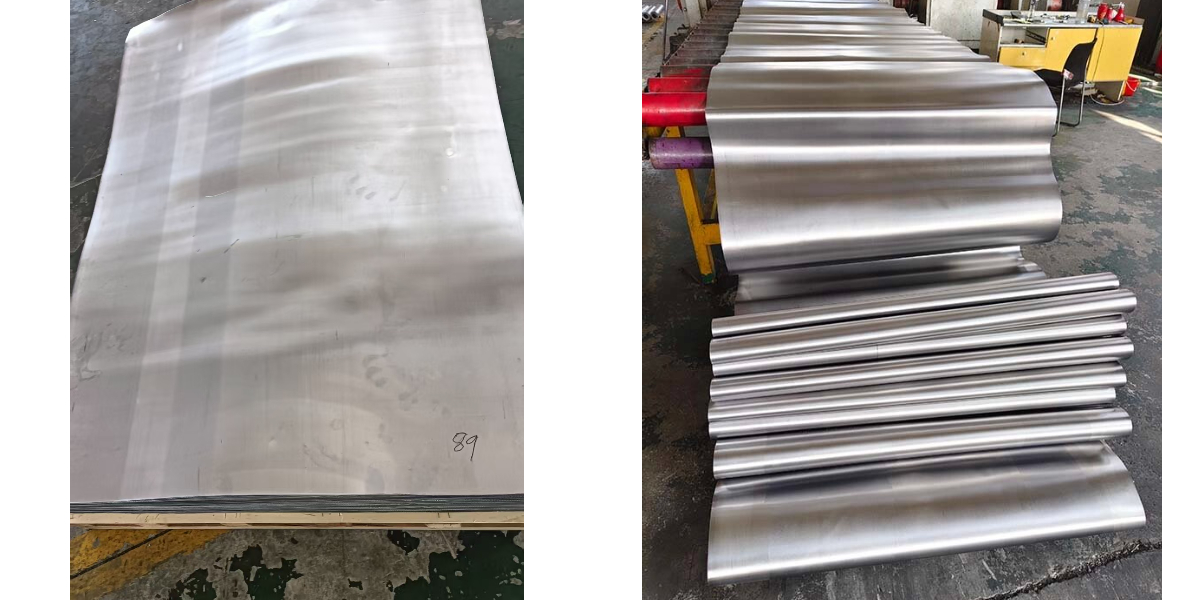

High-Quality Materials are the Foundation

The primary prerequisite for solving the gap problem is selecting high-performance protective materials. Traditional rigid lead plates, when dealing with complex corners, pipe openings, and irregular structures, often require multiple pieces to be spliced due to their difficulty in bending, thus creating more potential leakage points. Therefore, high-purity, uniformly textured, and highly flexible professional lead plates are crucial. For example, the lead plates supplied by Shandong Qite Radiation Protection Engineering Co., Ltd., with their outstanding bendability, allow for easy one-piece wrapping of complex nodes during construction, significantly reducing unnecessary seams from the source and laying a solid physical foundation for achieving a "seamless connection."

Systematic Processing is Key

Good materials alone are far from sufficient; they must be paired with standardized and rigorous processes. Professional treatment follows a systematic approach: when laying the lead sheet on walls and ceilings, a stepped overlapping method is used to ensure that vertical seams are completely covered; all seams must be fully welded using specialized equipment to ensure that the protective performance at the connection point is consistent with the sheet material itself. At the most critical door and window openings and wall corners, it is precisely the excellent flexibility of the lead sheet that allows for seamless bending and wrapping, fully overlapping and fixing it with lead glass window frames and protective doors. Finally, in conjunction with auxiliary materials such as barium sulfate mortar, a complete and uninterrupted three-dimensional shielding space is formed.

Conclusion

Therefore, the treatment of gaps in lead sheets in CT rooms is a hidden engineering project that integrates high-quality materials, meticulous craftsmanship, and a systematic approach. It reveals the true essence of modern medical safety construction: true reliability does not lie in the simple accumulation of materials, but in achieving a perfect closed loop in every detail through the deep integration of materials and processes, just like using Shandong Qite flexible lead plates, thereby creating a medical safety environment that gives people absolute peace of mind.