Lead Door

Lead doors, due to the high density of lead, possess strong radiation shielding capabilities, effectively protecting against X-rays, gamma rays, and more. Their robust structure and excellent sealing ensure long-term reliable use, making them widely applicable in locations requiring strict radiation protection, such as hospital radiology departments, nuclear power plants, and laboratories. They serve as a critical barrier to safeguarding both personnel and the environment.

Lead doors are specialized protective doors designed for high-radiation environments. Combining high-purity lead sheets with a reinforced structure, they effectively shield against ionizing radiation (such as X-rays and gamma rays), while maintaining both safety and durability. They have become essential protective equipment in the medical and nuclear industries.

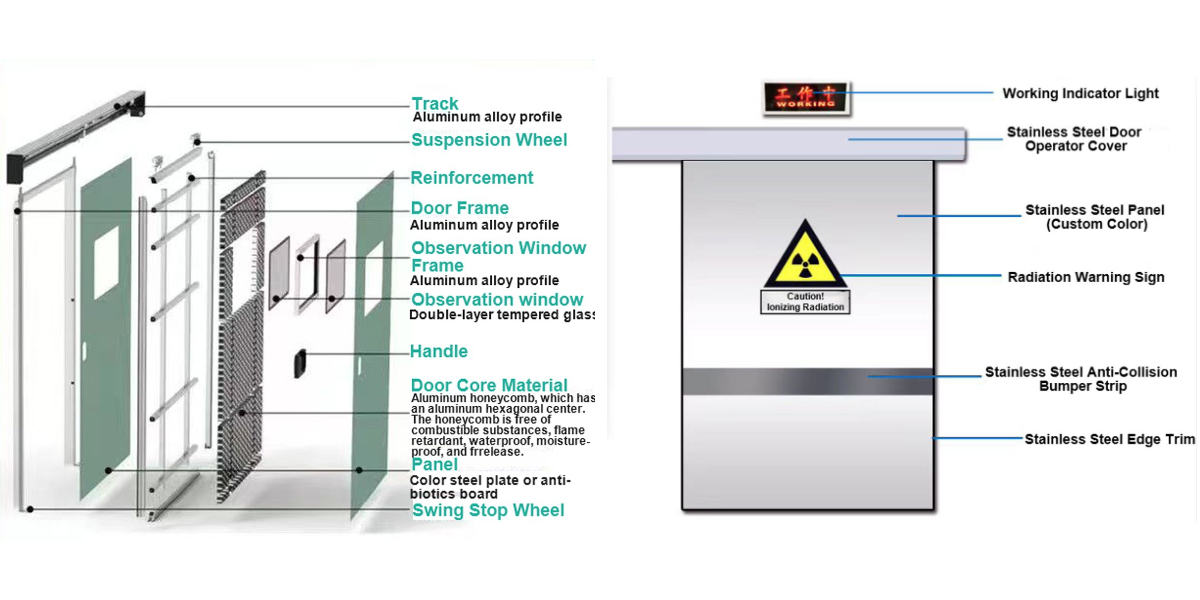

I. Structural Design

Core Shielding Layer

Inside, 2-20mm high-purity lead sheets (≥99.99%) are embedded, seamlessly joined to ensure zero radiation leakage. The thickness of the lead sheets can be customized based on the level of protection (e.g., 3-5mm is commonly used in CT rooms, while nuclear power plants require 15mm or more).

Reinforced Frame

Outer Layer: Covered with 1.2-2.0mm cold-rolled steel sheets or antibacterial stainless steel, with an anti-corrosion surface treatment.

Inner Lining: Supported by a high-strength steel frame with a deformation resistance exceeding 1000kg.

Edge: Labyrinth-type sealing strips (made of silicone or EPDM) are installed, ensuring a radiation leakage rate of less than 0.1%.

Smart Accessories

Hydraulic Buffer Hinges: Support over 100,000 opening and closing cycles, with silent door closing.

Interlocking Device: Synchronizes with the radiation equipment, automatically shutting off the equipment if the door is not closed.

Observation Window: Lead glass window (lead equivalent to the door), 15-30mm thick.

II. Core Advantages

Top-notch Protection

The density of lead (11.34g/cm³) absorbs over 99% of gamma rays, providing protection far superior to concrete (which requires only 1/10 the thickness for the same effect).

Safety and Convenience

Automatic Start and Stop: Infrared/foot sensor switches prevent personal contact and contamination.

Emergency Release Mechanism: Manual release in the event of a power outage, meeting fire escape standards.

Extremely Long Lifespan: Weather-resistant, stable operation in environments ranging from -30°C to 60°C. No risk of oxidation failure of the lead plate, with a service life exceeding 20 years.

Environmental Compliance: Complies with GBZ 130-2020, "Radiation Protection Requirements for Diagnostic Radiology," and IAEA safety standards.

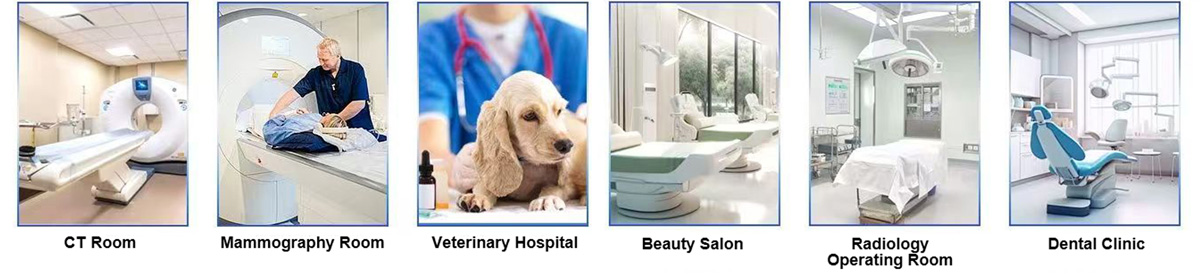

III. Application Scenarios

Medical

Hospital Radiology Departments (DR/CT Rooms), PET-CT Centers, and Radiotherapy Accelerator Treatment Rooms.

Dental Clinics: Protection against scattered radiation from small X-ray machines.

Nuclear Industry and Scientific Research

Nuclear Power Plant Fuel Storage Areas and Radioactive Waste Treatment Plants.

Laboratories: Nuclear physics research and isotope production workshops.

Special Industries

Industrial NDT Labs: X-ray Nondestructive Testing Chambers.

Security Inspection Systems: Cargo/Container Scanning Lanes.

Summary

Lead doors, with their military-grade protection standards, modular intelligent design, and adaptability to all scenarios, have become a critical line of defense for radiation safety. Their value lies not only in their shielding effectiveness but also in transforming complex protection requirements into reliable, easy-to-use engineering solutions, safeguarding both personnel health and environmental safety.

More Lead Door Photos

Hospital construction video

FAQ

Q: Do you support OEM production?

A: Yes. We can customize production based on your specifications (such as lead equivalent, dimensions, and material). Providing samples or design drawings will expedite the customization process.

Q: Can you accept small orders?

A: Yes. If the product is in stock, we can ship it immediately. If not, we will arrange flexible production scheduling (possibly combining production with other orders) to minimize lead times.

Q: Are samples free? How are shipping costs handled?

A: We can provide one free sample for standard products. Sample shipping costs must be prepaid. If you place a formal order, the shipping costs will be fully deducted from the order amount.

Q: How do we ensure transparency in order fulfillment?

A: We implement visual tracking throughout the entire process:

At the start of production: real-time photos of the workstations are sent;

After quality inspection: a radiation shielding performance test report is provided;

Before shipment: a video inspection is arranged for confirmation.