Lead Lined Board

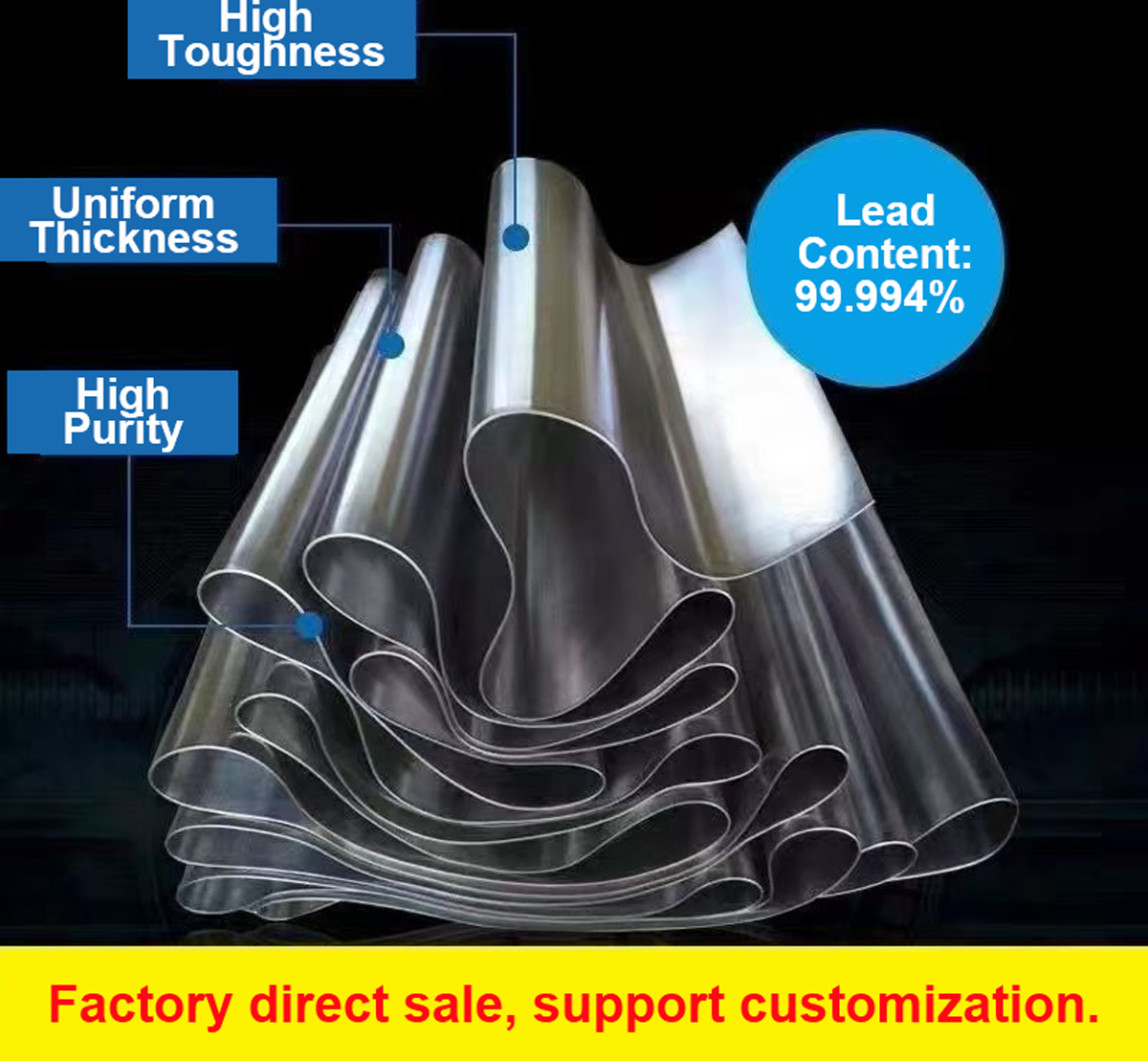

Smooth and Clean Surface: Free from particles with a refined finish.

Customizable Thickness: Tailored to meet diverse application needs.

Certified Quality: Supports inspection and meets X-ray shielding standards with guaranteed full thickness.

High Precision and Purity: Manufactured with no impurities and excellent material accuracy.

Dense and Durable: No internal pores, with strong resistance to radiation and corrosion.

Chemically Stable and Long-Lasting: High surface hardness and extended service life.

Product Introduction

Lead lined boards, also known as radiation shielding lead plates, are specially manufactured sheet materials made by rolling pure lead. Designed to protect against harmful radiation such as X-rays and gamma rays, these boards are widely used in medical, industrial, and nuclear environments. With customizable specifications and excellent shielding capabilities, our lead lined boards provide reliable protection and long-term durability.

Product Specifications

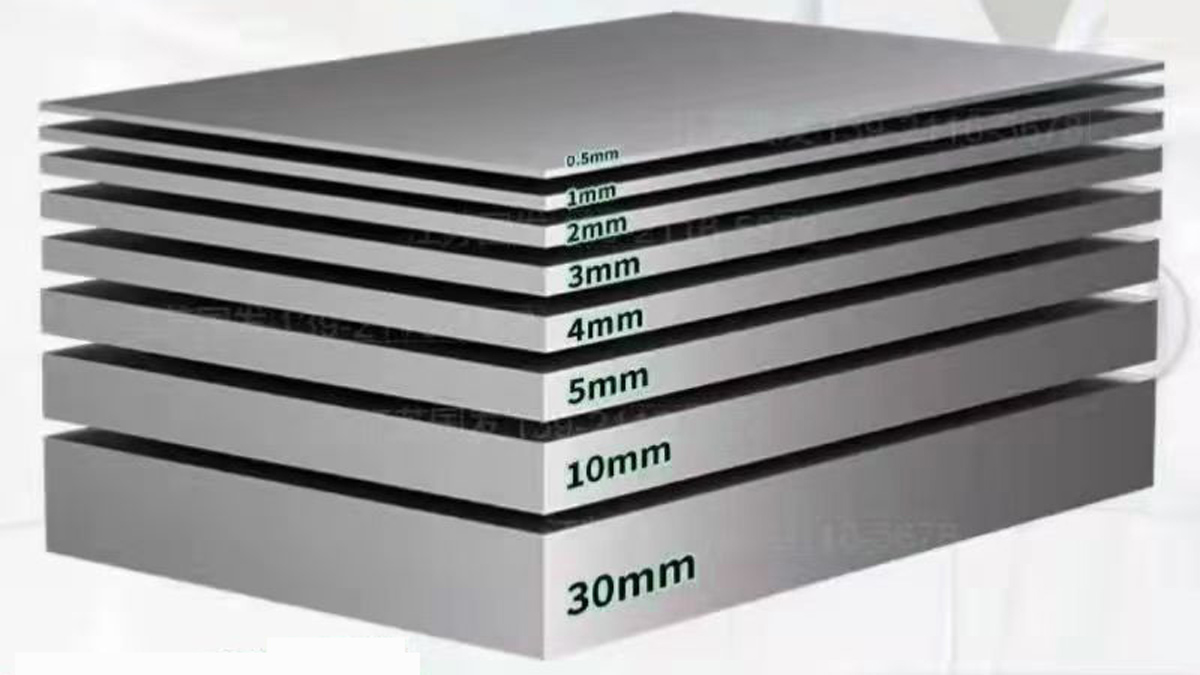

Thickness Range:

We offer a wide range of thickness options to meet different radiation protection requirements:

Standard sizes: 0.5mm, 0.6mm, 0.7mm, 0.8mm, 0.9mm, 1mm, 1.2mm, 1.5mm, 2mm, 3mm, 4mm, 5mm, 6mm, 7mm, 8mm, 9mm

Custom thickness: From 0.5mm up to 500mm available upon request

Size Options:

Maximum width: 1500mm

Maximum length: 30000mm

Custom dimensions available to suit specific applications

Other Available Products:

We also manufacture premium alloy lead products, including:

Lead pellets, lead balls, lead granules, lead shots (diameter: 1.0mm – 20mm)

High-purity lead ingots (purity: 99.99%)

Product Features

Our lead lined boards are engineered with superior performance characteristics:

High Density

Lead density: 11.34g/cm³ ensures excellent X-ray and gamma ray absorption

Ideal for high-level radiation shielding environments

Excellent Radiation Protection

Meets national and international radiation shielding standards

Effectively blocks harmful ionizing radiation to ensure personnel and environmental safety

Durability & Stability

Chemically stable and corrosion-resistant

Suitable for long-term use even in harsh environments like acid plants or nuclear facilities

Superior Surface Quality

Smooth, particle-free surface

High hardness and excellent compressive strength

Customizable & Versatile

Available in soft lead (pure) or hard lead (antimony alloy) options

Variants include boron-added polyethylene-lead composites for enhanced performance

Additional Properties

Non-porous, impurity-free, and acoustically insulating

Long service life with high shielding precision and dimensional consistency

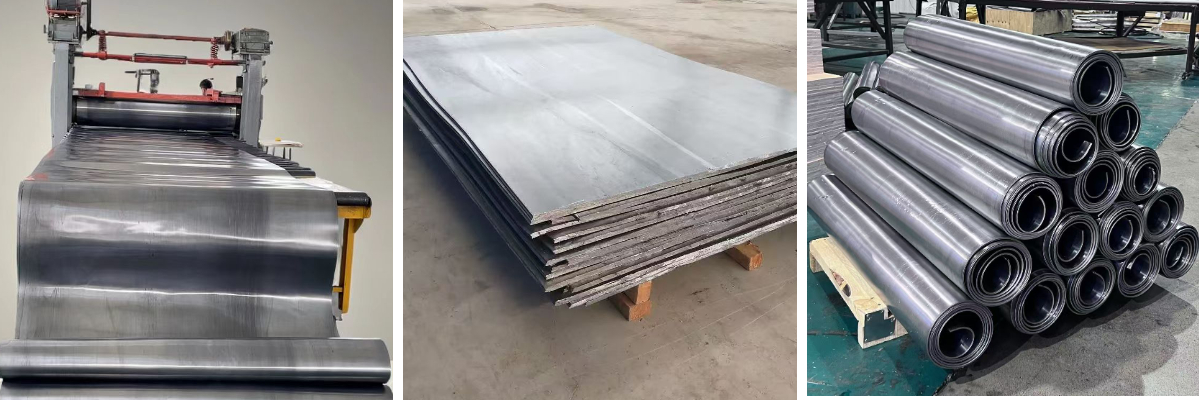

Product Structure

The structure of our lead lined board products is based on precision-rolled high-purity lead sheets. Depending on customer needs, the board can be:

Single-layer pure lead

Multi-layer composite with polymer or metal backing

Reinforced with antimony or boron for added hardness or neutron absorption

Each board is crafted to offer maximum radiation attenuation, ensuring consistent protection across its entire surface.

Application Scenarios

Medical Field

X-ray rooms, CT scan rooms, radiology departments, dental clinics

Radiation shielding for nuclear medicine and radiotherapy units

Industrial Field

Non-destructive testing (NDT) environments

Acid production, battery manufacturing, cable sheathing, and metallurgy

Used as counterweights in precision machinery

Other Sectors

Widely applied in mining, nuclear energy, and radiation shielding engineering

Also used in acoustic insulation and specialized battery systems

Known under different names in various industries, such as inspection shielding lead board, acoustic lead sheet, and anode lead plate