Why Lead Sheet is the Gold Standard for X-Ray Room Shielding

Why Lead Sheet is the Gold Standard for X-Ray Room Shielding

For decades, architects, hospital project managers, and radiology professionals have relied on one material above all others for safe, effective, and compliant radiation protection: lead. While new alternatives occasionally emerge, lead sheet for X-ray rooms continues to be the industry's trusted gold standard. Its unparalleled physical properties make it the most reliable choice for blocking harmful radiation. In this article, we explore the four key reasons why lead sheets for radiation shielding are the preferred solution and how Shandong Qite Radiation Protection Engineering Co., Ltd. provides the highest quality materials for your projects.

1. Unmatched Density and Shielding Efficiency

The core principle of radiation protection is attenuation—weakening radiation to safe levels. The effectiveness of a material in achieving this is directly tied to its density. Lead boasts an exceptionally high density (11.34 g/cm³), which allows it to absorb and scatter X-ray photons effectively.

This high density means that a relatively thin layer of lead sheet for X-ray rooms can provide the same level of protection as a much thicker, bulkier barrier made from less dense materials like concrete or specialized drywall. This efficiency is critical in modern medical facilities where space is at a premium. When you specify high-quality Lead Sheets for Radiation Shielding from a certified manufacturer like Shandong Qite, you are choosing the most space-efficient and physically effective barrier available, ensuring your Lead Sheet For X Ray Rooms project meets all safety protocols without compromising valuable room space.

2. Superior Flexibility and Ease of Installation

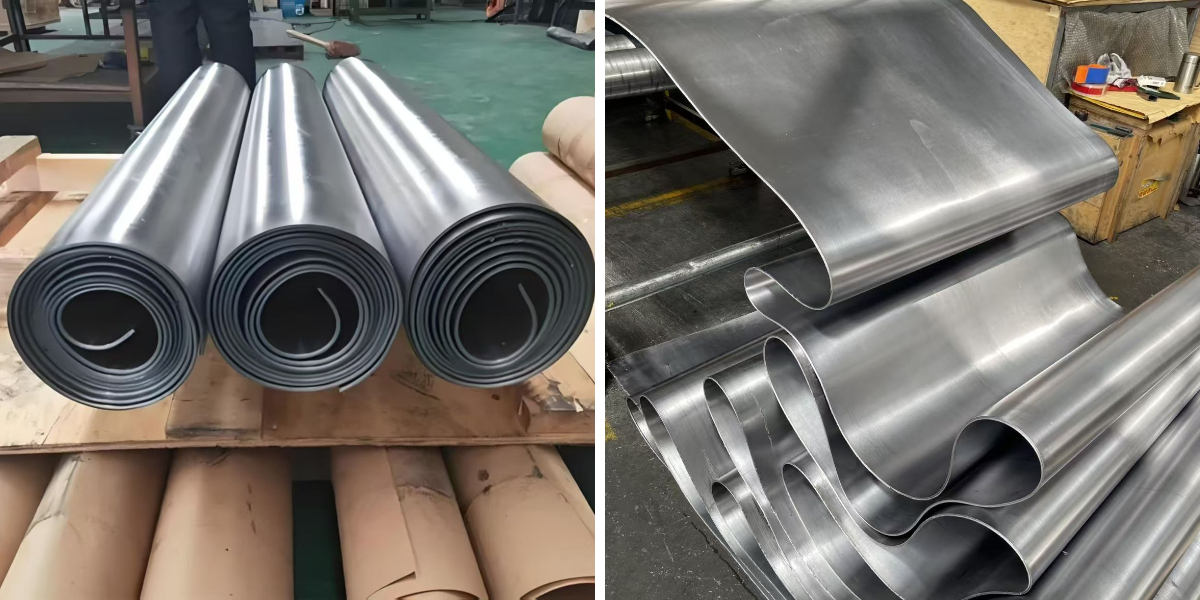

A common misconception is that lead is a rigid and difficult material to work with. In reality, pure lead is highly malleable. This flexibility is a tremendous advantage during the construction of an X-ray suite.

Quality lead sheet for X-ray rooms can be easily cut and shaped to conform to complex architectural details. It can be seamlessly applied to walls, ceilings, and floors, and molded around pipes, electrical conduits, and ventilation ducts without creating gaps in protection. This ensures a continuous radiation barrier, which is absolutely vital for safety. The teams at Shandong Qite Radiation Protection Engineering Co., Ltd. understand these nuances. We provide Lead Sheets for Radiation Shielding that are manufactured to be pliable and easy for installers to work with, reducing labor time and ensuring a perfect, gap-free fit for any Lead Sheet For X Ray Rooms application, from large hospitals to small dental clinics.

3. Proven Long-Term Durability and Cost-Effectiveness

Radiation shielding is a long-term investment in safety. The installed system must perform flawlessly for the entire lifespan of the facility, which could be decades. Lead offers unparalleled and proven long-term stability.

Unlike some materials that can degrade, settle, or crack over time, a properly installed lead sheet is inert and maintains its structural integrity indefinitely. It requires zero maintenance and won't need to be replaced, providing permanent peace of mind. This durability also translates into significant cost-effectiveness. While the initial material cost may be comparable to some alternatives, the long-term value is superior. You invest once in a Lead Sheet For X Ray Rooms solution that will last. By choosing Shandong Qite as your supplier for lead sheets for radiation shielding, you secure not only a premium product but also exceptional value over the life of your facility.

4. Regulatory Compliance and Environmental Recyclability

Meeting stringent international safety standards (from organizations like the NCRP, AAPM, and IEC) is non-negotiable. Lead sheet for X-ray rooms is the most widely recognized and accepted material for meeting these codes. Health physicists and safety officers are thoroughly familiar with its performance metrics, making the approval process smoother.

Furthermore, in an era focused on sustainability, lead shines due to its recyclability. It is one of the most recycled materials in the world. The lead sheets for radiation shielding used today, including those provided by Shandong Qite Radiation Protection Engineering Co., Ltd., often contain a high percentage of recycled content. At the end of a facility's life, the lead can be completely recovered and recycled without any loss of its protective properties, making it an environmentally responsible choice for your Lead Sheet For X Ray Rooms project.

Conclusion: Partner with a Trusted Leader in Radiation Protection

The combination of unmatched density, flexibility, durability, and compliance makes lead sheet for X-ray rooms the undeniable gold standard for radiation shielding. When the safety of patients and staff is the priority, there is no room for compromise.

Choosing the right supplier is just as critical as choosing the right material. Shandong Qite Radiation Protection Engineering Co., Ltd. stands as a leading manufacturer in China, offering premium-grade Lead Sheets for Radiation Shielding. We guarantee precise lead equivalence, superior craftsmanship, and full compliance with international standards.

Ready to specify the best shielding for your project? Contact Shandong Qite today for a free consultation and quote. Let our expertise ensure your Lead Sheet For X Ray Rooms installation is safe, compliant, and built to last.