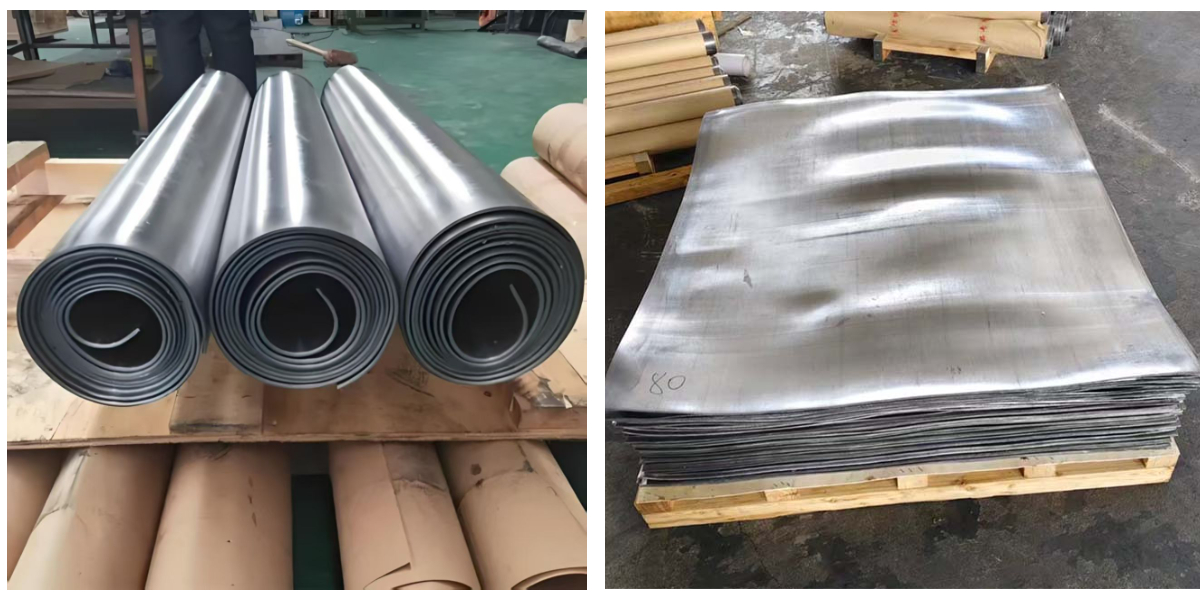

Pure Lead Sheet

Ultimate protection: Lead density (11.34g/cm³) and high atomic number (82) provide the industry's top radiation shielding efficiency, 1mm thickness can block more than 90% of medical X-rays.

Economical and durable: Compared with alternative materials such as tungsten alloy, the cost is reduced by 40%-60%, and the corrosion resistance life exceeds 20 years.

Flexible adaptation: Soft texture (hardness HB 4-5), can be cut and bent, and fit complex structures (such as curved walls, pipe wrapping).

Pure and reliable: Purity ≥ 99.99%, no impurities interfere with shielding stability, and passed ISO and IAEA safety certification.

Environmentally friendly recycling: Waste lead plates can be 100% recycled, melted and reused to reduce resource waste.

Pure lead plate product introduction

1. Basic technical specifications

Pure lead plate implements the national standard GB/T 1470-2020 No. 1 lead standard, purity ≥99.994%, key impurity (antimony/copper/bismuth) content ≤0.006%. Density is stable at 11.34 g/cm³ (cold rolling process eliminates pores), thickness range is 0.5mm~200mm (1-3mm is commonly used in medical treatment, 50-150mm is required for nuclear industry), standard size is 1m×2m (customizable 1.5m×6m), thickness tolerance is ±0.1mm. Mechanical properties: tensile strength 10-15 MPa (soft state and easy to process), elongation ≥40%, support 180° bending without cracking.

2. Five core advantages

Extreme shielding effectiveness: The atomic number of lead (82) absorbs radiation efficiently through the photoelectric effect. The attenuation rate of 1mm thickness for 120kV medical X-rays is >99.5%, and 150mm thickness can shield 99% of cobalt-60 gamma rays (1.25MeV).

Significant cost advantage: The price of raw materials is only 1/3 of tungsten alloy and 1/2 of lead boron polyethylene, and the comprehensive cost of large-scale projects is reduced by more than 40%.

Flexible adaptability: Mohs hardness 1.5 (close to the hardness of fingernails), can be cold cut, rolled, and stamped, and perfectly fits curved walls and special-shaped pipe structures.

Ultra-long service life: A dense PbO₂ passivation film is naturally generated on the surface, and the service life in indoor environment is >30 years, without the risk of aging and failure.

100% recycling: The energy consumption of recycled smelting is less than 5% of the original lead, and the recycling value of waste lead plates can reach 80% of the price of new materials.

3. Core application scenarios

Medical protection:

CT room wall: ≥2.5mm lead equivalent (140kV working condition), lead welding seal of joints + anti-leakage radiation detection.

Mobile protective screen: 3mm lead plate + steel structure frame (70kg/m²), with universal brake wheels at the bottom.

Key protection of nuclear industry:

Spent fuel storage pool: 100mm double-layer lead plate + high-density concrete, shielding neutron/γ mixed radiation.

Isotope production hot room: 99.99% high-purity lead brick wall to avoid radiation activation and secondary radiation.

Precision equipment guarantee: The electron microscope room uses 1mm lead plate to fully cover the wall, reducing the environmental background radiation to <0.1μSv/h.

4. Engineering implementation specifications

Structural support: The lead plate bearing limit is ≤200kg/m², and the angle steel frame (spacing ≤400mm) needs to be welded to disperse the load.

Joint treatment: Step-type overlap (overlap width ≥ 20mm), lead-tin solder (Sn63/Pb37, melting point 183℃) sealing, gap ≤ 1.5mm.

Surface protection: Cover with 0.5mm food-grade PVC film or spray epoxy resin coating (thickness ≥ 80μm required for nuclear industry) to prevent lead oxide dust from escaping.

Acceptance inspection: Annual inspection uses ⁶⁰Co radioactive source (1.33MeV γ ray), and shielding attenuation rate must be > 99.9%.

Scientific selection basis: Radiation type (α/β/γ/X-ray), energy intensity (kV or MeV), installation space restrictions must be provided, and the lead equivalent requirement must be calculated by an organization with CMA qualification. For example: 150kV industrial flaw detection X-ray protection requires ≥ 4mm lead plate, and nuclear power plant γ-ray shielding requires ≥ 80mm lead equivalent.