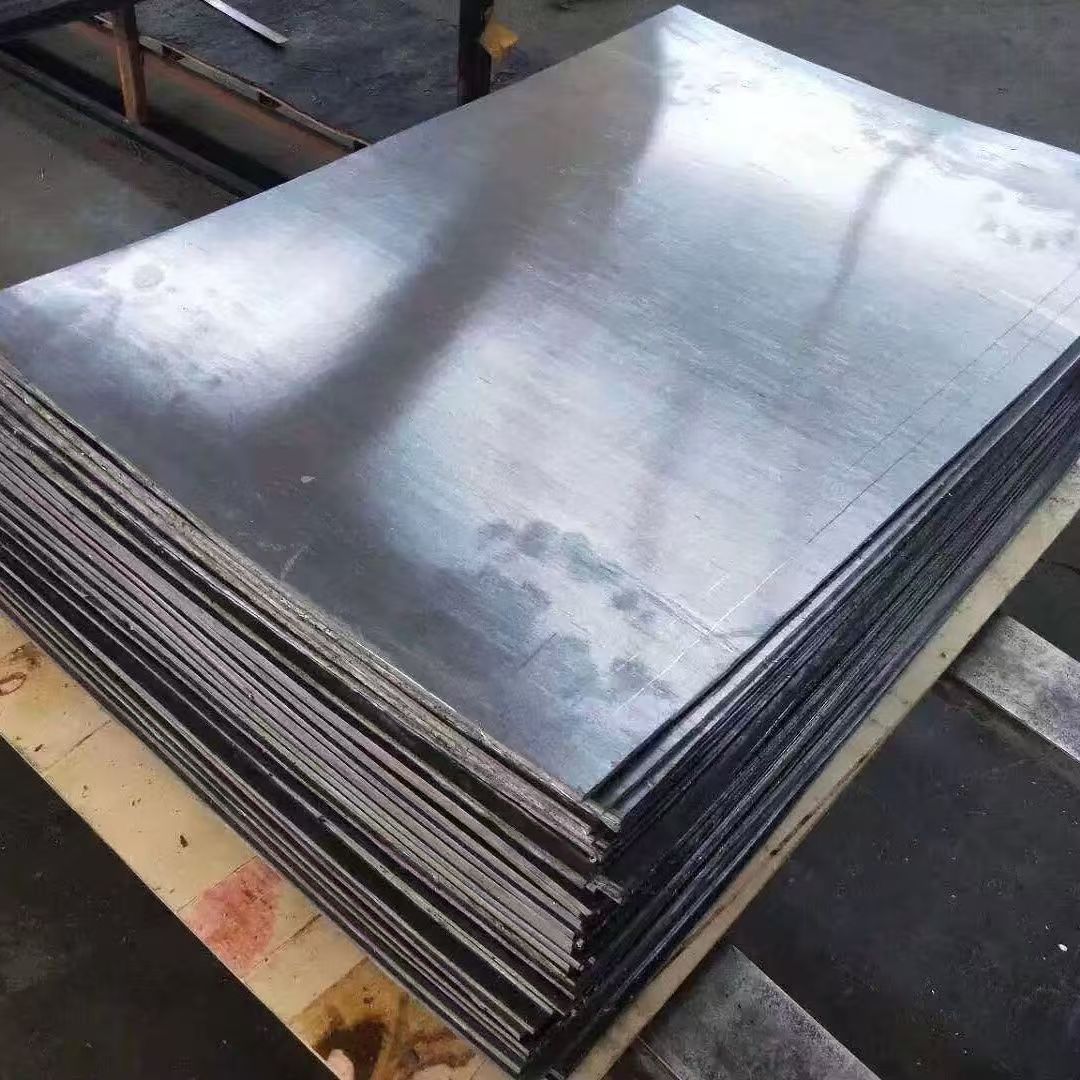

Lead Shielding Sheets

Efficient protection: high lead density (≥11.34g/cm³), can block X-rays, gamma rays, etc., protection efficiency ≥99%, in line with GBZ/T 250-2014 standard.

High-purity material: lead purity ≥99.99%, anti-oxidation treatment, strong corrosion resistance, life span of more than 20 years.

Flexible and lightweight: adopt lead alloy or composite structure, thickness 1-10mm optional, weight is 30% lower than traditional lead plate, easy to cut and install.

Safe and environmentally friendly: the surface is covered with PVC/stainless steel protective layer to prevent lead powder from falling off, passed ROHS certification, no pollution risk.

Strong adaptability: support customized size and curvature, tight seams (≤0.5mm), suitable for complex scenes such as CT room and nuclear medicine department.

Lead shielding plates are core materials used to protect against ionizing radiation (such as X-rays and gamma rays) in the medical, nuclear and scientific research fields. They absorb radiation energy through the physical properties of high-purity lead to ensure personnel safety and environmental compliance.

Core performance and technical parameters

High-efficiency radiation protection

Lead equivalent meets the standard: lead purity ≥99.99%, density 11.34g/cm³, lead equivalent 0.5-5mmPb optional, protection efficiency ≥99% (according to GBZ/T 250-2014 standard), suitable for different radiation intensity scenarios.

Broad-spectrum protection: effectively shielding X-rays, gamma rays and some neutron radiation with an energy range of 10keV-10MeV, meeting the protection needs of CT rooms, PET-CT, linear accelerator rooms, nuclear medicine departments, etc.

Composite structure design

Lightweight innovation: lead-polymer composite materials (such as lead rubber, lead polyethylene) or lead alloy sandwich structure are used, the thickness of 1-10mm can be customized, the weight is 20%-30% lower than the traditional pure lead plate, and the load-bearing pressure of the wall is reduced.

Multi-layer protection: the surface is covered with 0.5-1.2mm stainless steel plate, PVC or fireproof coating, and the inner lead plate is seamlessly spliced (the seam is ≤0.3mm), which has the functions of anti-oxidation, anti-lead powder shedding and mechanical protection.

Safe and environmentally friendly characteristics

Zero pollution process: the lead layer is coated with polymer or electrolytic passivation, passed ROHS and SGS certification, no lead vapor release, lead leakage rate <0.1μg/m³, in line with occupational health and environmental protection requirements.

Fireproof and corrosion-resistant: the surface material has a fire resistance grade of A (GB 8624-2012), acid and alkali resistance, moisture and mildew resistance, adapt to -30℃ to 80℃ environment, and a service life of more than 15 years.

Flexible installation and adaptation

Modular design: standard plate size 1200×2400mm, supports secondary processing such as cutting, bending, drilling, etc., arc radius ≥50mm, can fit special-shaped structures such as walls, doors and windows, pipes, etc.

Convenient fixation: reserved bolt holes or adhesive + keel reinforcement method, lead tape (lead equivalent ≥0.5mmPb) superimposed at the joints to ensure no radiation leakage.

Intelligent detection and customization services

Controllable quality: third-party test reports (such as CNAS certification) are provided for each batch, including uniformity of lead content, protective performance and environmental protection indicators.

Scenario customization: supports integrated solutions such as lead glass observation windows, electric lead doors, lead screens, etc., and dose alarms can be attached to monitor radiation leakage in real time.

Application scenarios

Medical field: radiology department, interventional operating room, radiotherapy center, nuclear medicine ward.

Industry and scientific research: nuclear power plants, industrial flaw detection rooms, laboratory radiation device shielding.

Certification and Quality Assurance

Passed ISO 9001 and ISO 14001 system certification, in compliance with NCRP and ICRP international protection standards, with a 10-year warranty, providing radiation protection solution design, installation and regular testing services.

Lead shielding plates, with high protection, safety and scene adaptability, build a reliable radiation protection system for multiple industries, helping to achieve safe operation and compliance management.