Manual Clean Room Door

Core advantages of clean room doors

High sealing: Special materials and structural design are used to effectively block particles, dust and microorganisms to ensure that the cleanliness meets the standards.

Durable materials: Stainless steel or aluminum alloy frames are corrosion-resistant and easy to clean, suitable for high-frequency use and strict disinfection environments.

Automatic control: Optional induction or pneumatic switches can reduce contact pollution and improve efficiency.

Compliance and safety: Comply with GMP/ISO standards, fireproof and anti-static, to ensure production and personnel safety.

Flexible customization: Adapt to different cleanliness level requirements and optimize space and airflow organization.

Summary: Taking into account both performance and reliability, it is a key barrier in the pharmaceutical, electronics and other industries.

Cleanroom doors are core facilities to ensure the stability of clean environment. They are designed for high cleanliness scenes such as medicine, electronics, semiconductors, and biological laboratories. Through scientific structure and material selection, they ensure space sealing, durability and ease of operation, and meet ISO 1-9 clean standards and industry specifications. The following are its detailed product features:

1. Structural design

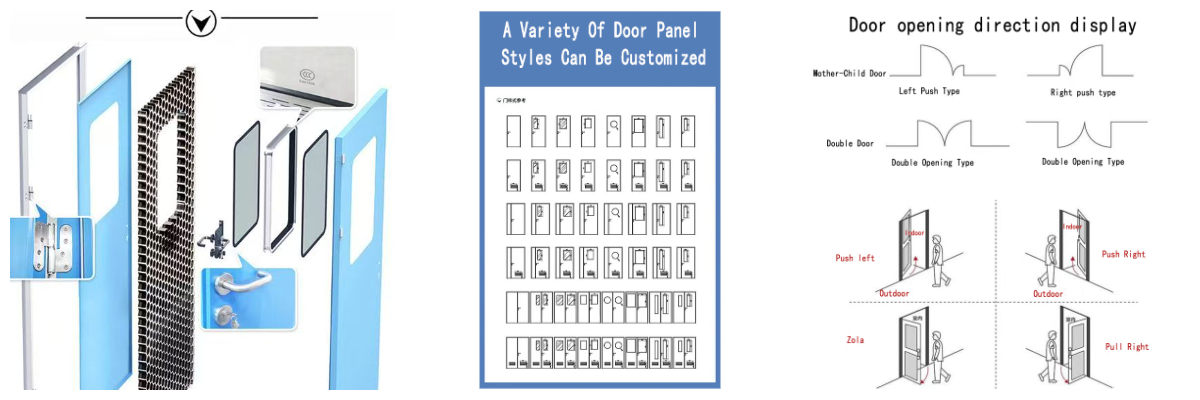

Door body type: optional sliding, swing or fast rolling shutter type, suitable for different space layouts. Sliding doors save space, swing doors have strong sealing, and fast rolling shutter doors are suitable for high-frequency traffic areas.

Double-layer closed structure: The door frame and door leaf use embedded sealing strips (silicone or EPDM material), combined with an automatic lifting bottom sealing system, to fully block the exchange of internal and external particles.

Observation window design: Standard double-layer tempered glass window, some models can be upgraded to anti-fog and anti-static glass, which is convenient for real-time monitoring of the indoor environment.

2. Material and craftsmanship

Frame material: 304/316 stainless steel or anodized aluminum alloy, corrosion-resistant, acid-resistant, smooth surface without dead corners, easy to clean and disinfect.

Door panel material: honeycomb aluminum plate, antibacterial coated steel plate or high-strength tempered glass, both lightweight and pressure-resistant, some models have built-in fireproof rock wool (Class A fireproof standard).

Sealing components: high elastic sealing strips, airtight compression devices, combined with seamless welding technology, to ensure that the door body airtightness reaches ISO Class 5 or above.

3. Functional configuration

Intelligent control system: supports fingerprint recognition, card swiping, infrared sensing or pneumatic switch to reduce contact pollution; linked clean room air shower system or interlocking device to prevent air flow turbulence.

Safety protection: emergency escape push rod, anti-pinch finger sensor, power-off manual opening function, in line with fire protection and safety regulations.

Cleanliness assistance: optional ion air curtain, self-cleaning device or ultraviolet sterilization module to further reduce the risk of contamination.

4. Application scenarios

Pharmaceutical industry: used in GMP workshops, sterile preparation rooms, and vaccine production lines to prevent cross contamination.

Electronic industry: adapted to wafer fabs and chip packaging workshops, anti-static design protects precision components.

Biological laboratories: cooperate with negative pressure environment to ensure the safety of pathogenic microorganism isolation.

5. Technical standards and certifications

Comply with international clean standards such as ISO 14644, GMP, and FDA, and pass fire protection (EN 13501), anti-static (ESD S20.20) and air tightness testing certifications.

Customized service: provide solutions based on cleanliness level (such as Class 100, Class 10,000), door opening size (conventional 1.8m×2.2m, customizable) and environmental requirements (temperature, humidity, pressure difference).

6. Installation and maintenance

The professional team provides on-site measurement, embedded installation and air tightness debugging to ensure seamless connection with the wall.

Regular maintenance recommendations: seal strip replacement cycle (1-2 years), track cleaning and lubrication, sensor sensitivity detection, extend the service life to more than 10 years.

Summary: Clean room doors have become the key line of defense for clean environments through precision design and high-end materials, taking into account efficient isolation, intelligent control and long-term stability, helping companies achieve production safety and compliance management. When choosing, it is necessary to combine the cleanliness level, frequency of use and special functional requirements to match the best solution.