Laboratory Sliding Door

The laboratory-specific airtight sliding door adopts a multi-layer sealing design (magnetic + EPDM strips), with airtightness reaching ISO 14644 Class 7-8, air leakage ≤0.03Pa·m³/s, accurately maintaining the indoor pressure difference to prevent cross contamination. The door body is made of 304 stainless steel or explosion-proof glass, with an acid- and alkali-resistant coating on the surface, and can withstand highly corrosive reagents and high-frequency disinfection. Equipped with an intelligent induction opening and closing system, it supports contactless operation and reduces the risk of human contact. It can be opened manually in an emergency power off, with an anti-pinch force of <50N and a high safety factor. The embedded track is dust-proof and noise-reducing, suitable for high-precision environments such as clean rooms and PCR laboratories, and meets the dual needs of biosafety and chemical protection.

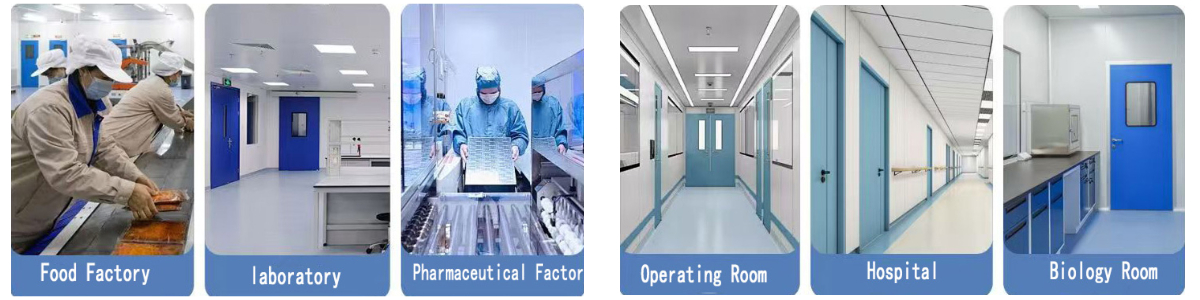

Laboratory sliding door airtight door is designed for high cleanliness and high safety experimental scenes, meeting the stringent requirements of biosafety laboratories (BSL-2/3), PCR laboratories, chemical analysis rooms and other environments, with precise airtight isolation, corrosion resistance and intelligent management functions. The following is a detailed technical description:

1. Core structure and material

Door frame: Made of 304 stainless steel or high-strength electrophoretic aluminum alloy, with nano-antifouling coating on the surface, resistant to strong acid, strong alkali and organic solvent corrosion, resistant to chemical disinfectants (such as 84, peracetic acid), frame thickness ≥2.5mm, load-bearing ≥300kg, service life ≥300,000 times of opening and closing.

Door leaf configuration: optional 10-12mm tempered explosion-proof glass (embedded wire explosion-proof film) or double-layer galvanized steel sandwich structure (core material is polyurethane foam, sound insulation ≥40dB), seamless surface treatment, in line with ISO 14644-1 Class 7 cleanliness standard.

Sealing system: Five-layer dynamic sealing - top EPDM elastic sealing strip, bottom automatic lifting silicone sweeping seal, double-sided magnetic adsorption seal, door frame pressure compensation strip and internal airtight cavity, air leakage ≤0.03Pa·m³/s, pressure difference maintenance accuracy ±2Pa, ensuring the stability of positive/negative pressure environment in the laboratory.

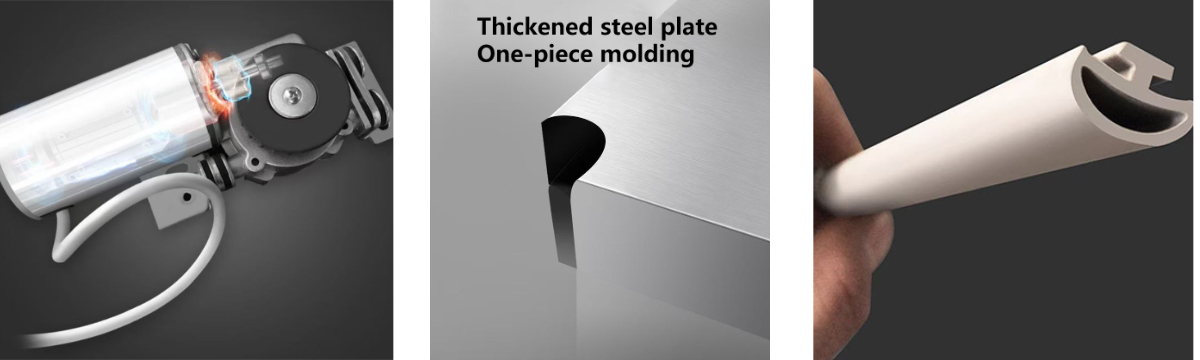

2. Intelligent control and safety protection

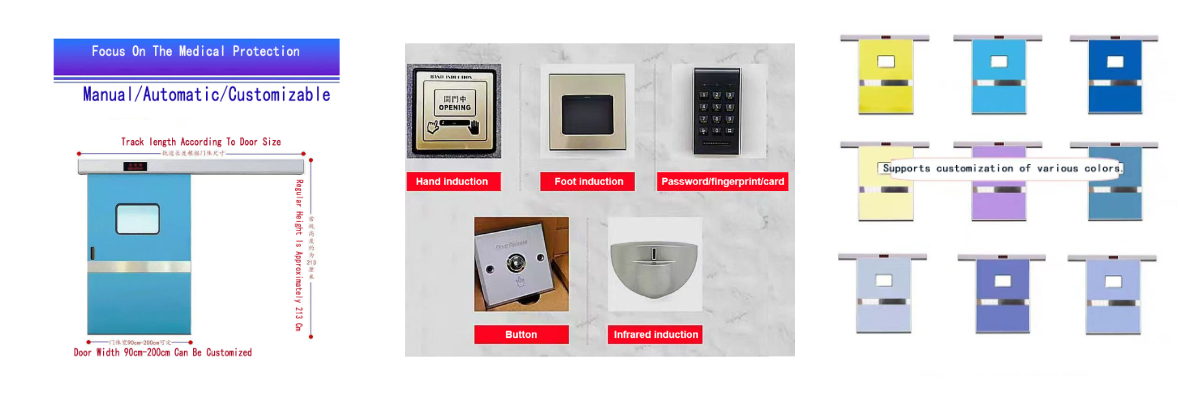

Contactless opening and closing: standard infrared/microwave radar dual-mode sensing, adjustable detection distance 0.2-5m, support foot touch switch, card swiping or palm vein recognition (optional), reducing the risk of personnel contact contamination.

Safety protection mechanism: resistance rebound sensitivity ≤5N, anti-pinch force <50N; manual opening force ≤80N in case of power failure/failure, emergency escape device complies with EN 16005 safety standards.

Environmental linkage: can be connected to the laboratory intelligent management system, linked with the exhaust system and VAV variable air volume valve, automatically adjust the supply and exhaust air volume after the door is closed to maintain pressure difference balance.

3. Functional adaptation and scene customization

Biosafety enhancement: The joints between the door and the wall are sealed with antibacterial silicone, which has passed the GB/T 31430 antibacterial certification; the door leaf can be equipped with an optional ultraviolet disinfection module (wavelength 265nm) to achieve automatic surface sterilization.

Chemical protection: The track and hinge are made of 316L stainless steel, which can withstand high-temperature and high-pressure steam sterilization (135℃/30min); the edge of the door leaf is coated with Teflon coating to prevent adhesion and corrosive dust.

Customized design: The door body size can be customized (width 800-2500mm, height 2100-3500mm), supporting one-way/two-way sliding and folding composite door types; the color can be selected from RAL color cards or matched with laboratory VI logos.

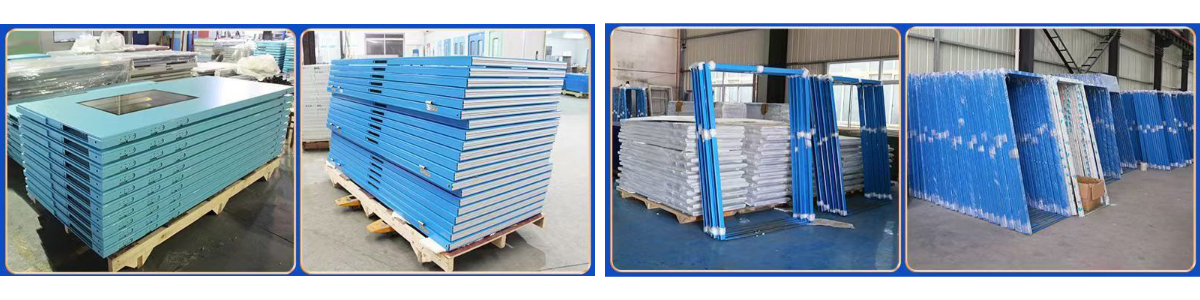

4. Installation and operation and maintenance guarantee

Track system: heavy-duty embedded track, silent slider design, sliding noise ≤35dB, equipped with dust cover to avoid dust accumulation; track load-bearing ≥500kg, suitable for frequent opening and closing scenes.

Fast maintenance: Modular component design, core components such as motors and sensors can be replaced within 10 minutes; remote diagnostic interface is provided to monitor the number of door opening and closing times, sealing loss and other data in real time.

Clean construction: The installation adopts dust-free operation technology, the joints are sealed with glue injection and undergo 48-hour airtightness testing to ensure that they meet the standards upon delivery.

5. Certification and standards

Passed ISO 14644 clean room certification, EN 14122 laboratory safety standard, GB 50736 building airtightness specification, and some models meet the construction requirements of BSL-3 level biosafety laboratories. The fire-resistant door body (optional) passes the 1-hour fire resistance test (GB/T 7633) and is suitable for hazardous chemical laboratories.

Summary

The laboratory airtight sliding door is based on precision sealing technology, corrosion-resistant materials and intelligent control. It effectively isolates harmful substances and maintains stable environmental parameters, providing all-round protection for scientific research experiments, sample protection and operator safety. It is the core infrastructure of modern high-standard laboratories.