Hospital Sliding Door

Space Efficiency: The sliding opening mechanism saves space and maximizes the utilization of passageways and room area.

Sound Insulation and Cleanliness: Effectively isolates noise, and the airtight design prevents dust and germs from crossing.

Safety and Convenience: Automatic anti-pinch sensors ensure safe and smooth passage for medical staff and patients.

Durable and Easy to Maintain: Made of sturdy and wear-resistant materials, it requires simple daily maintenance and has a low lifespan cost.

The hospital airtight sliding door is designed for high-cleanliness and high-safety medical scenes. It integrates airtightness, antibacterial properties, and intelligence to meet the stringent requirements of operating rooms, ICUs, laboratories, pharmacies and other areas. The following are detailed technical parameters and functional descriptions:

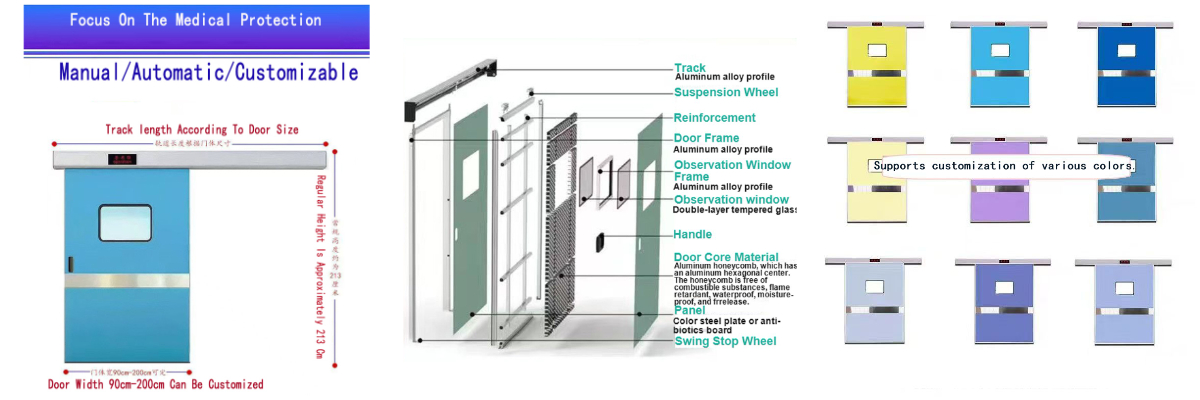

1. Core structure and material

Door frame: medical-grade 304 stainless steel or high-strength aluminum alloy, anodized or fluorocarbon sprayed on the surface, corrosion-resistant and resistant to chemical disinfectants (such as hydrogen peroxide, chlorine-containing preparations), frame thickness ≥2.0mm, load-bearing capacity ≥200kg, service life ≥200,000 openings and closings.

Door leaf material: The outer layer is 8-12mm tempered explosion-proof glass (optional frosted/transparent), with an embedded antibacterial coating, in line with the GB/T 31430-2015 antibacterial standard; or double-layer metal plate sandwiched with polyurethane foam core material, sound insulation ≥35dB, excellent thermal insulation performance.

Sealing system: Quadruple airtight structure - EPDM elastic sealing strip on the top, automatic lifting sweeping seal on the bottom, magnetic sealing strips on both sides, and embedded pressure compensation strips on the door frame. The airtightness reaches ISO 14644-1 Class 8 standard, and the air leakage is ≤0.05Pa·m³/s, ensuring the stability of the positive/negative pressure environment in the room.

2. Intelligent control system

Induction opening and closing: Standard infrared/microwave radar dual-mode induction, adjustable detection distance of 0.3-3m, support foot touch switch, hand induction and card swiping/face recognition (optional), non-contact operation reduces the risk of cross infection.

Safety protection: The door body automatically rebounds when encountering resistance (triggering when resistance ≤10N), anti-pinch force <50N; equipped with emergency escape device, manual push force ≤100N can be opened when power is off, in line with JG/T 257-2009 "Medical Sliding Automatic Door" safety specifications.

Linkage control: It can be connected to the hospital building automatic control system, linked with fire protection, air conditioning, and clean equipment, and automatically shut down and start the pressurized smoke prevention mode in case of fire.

3. Functional configuration and scene adaptation

Special for clean areas: The bottom of the door body is equipped with a self-lifting sealing strip, which has zero gap with the ground after closing, blocking dust, insects and harmful gases; the door frame has a built-in airtight pressure sensor to monitor the pressure difference in real time and feedback to the central control screen.

High-frequency disinfection environment: The door body surface is seamlessly designed, supporting daily high-frequency alcohol and chlorine-containing disinfectant wiping; the hinges and tracks are made of rust-proof materials and can withstand high-temperature steam sterilization (optional).

Customization options: The door body width is 800-2000mm and the height is 2000-3000mm, which can be customized; one-way/two-way sliding and sliding folding composite door types are provided; the color supports RAL standard color card or hospital VI customization.

4. Installation and maintenance

Track system: Embedded heavy-duty silent track, bearing strength ≥300kg, sliding noise ≤40dB; track groove dustproof design, daily cleaning only requires vacuuming.

Fast maintenance: Modular structure design, core components such as motors and sensors support 15-minute quick replacement; provide remote fault diagnosis and life cycle management services.

5. Certification and standards

Passed ISO 9001 quality management system, ISO 13485 medical device certification, GB 50736 "Medical Gas Engineering Technical Specifications" and other authoritative tests, the test report covers key indicators such as air tightness, fire resistance (some models reach 1 hour fire resistance), and electromagnetic compatibility (YY 0505-2012).

Summary

Hospital airtight sliding doors are based on precision manufacturing technology and intelligent technology, taking into account infection prevention and control, environmental control and medical operation efficiency. They are standard configurations for modern medical space construction and provide reliable guarantees for patient safety and medical quality.