Lead Screens

Superior Protection: Built-in high-purity lead plates effectively shield against various ionizing radiations such as X-rays and gamma rays, providing a safe and reliable protective barrier for personnel.

Flexible Mobility: Equipped with sturdy casters and a steering mechanism, it is easy to move and precisely position, quickly adapting to the temporary protection needs of different work areas.

Edible Design: The robust and lightweight structure, with some models featuring observation windows, ensures both ease of operation and a clear field of vision, while also guaranteeing stability and safety during use.

Rugged and Durable: Utilizing high-quality materials and a robust structure, it is wear-resistant, corrosion-resistant, and durable, effectively reducing long-term operating and maintenance costs.

Lead screen for operating room product introduction

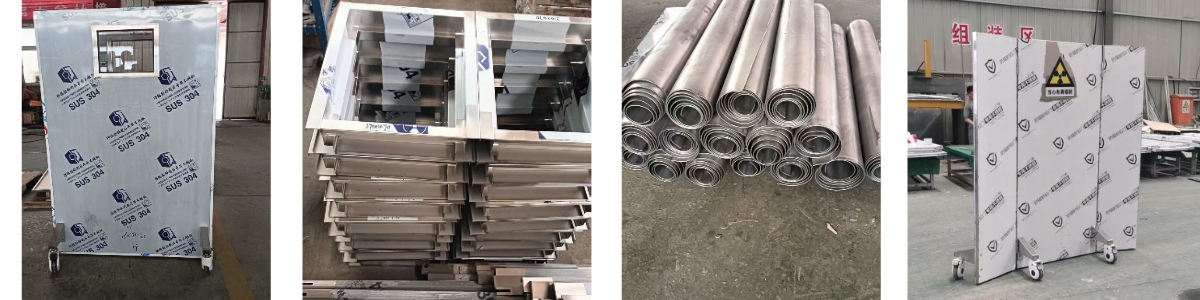

Core material and structure

Radiation shielding layer: adopts ≥99.99% high-purity lead plate laminated package, provides 2.0~3.0mmPb lead equivalent protection, and specifically blocks the 150kVp-level scattered radiation generated by C-arm machine during surgery.

Surface protection: 304 medical grade stainless steel one-piece molded shell, completely eliminates seams through seamless welding process, and withstands high-frequency disinfection of strong disinfectants such as hypochlorite and peracetic acid every day.

Visual system: 20mm thick lead glass window (lead equivalent ≥2.0mmPb), light transmittance ≥82% to ensure no blind area in the surgical field, and the edge is frosted for anti-glare.

Load frame: aviation aluminum alloy frame (thickness ≥3mm), passed IK08 impact resistance certification, and built-in medical silicone anti-collision buffer layer at the four corners.

Core functions and roles

Dynamic radiation protection

Freely move and position during surgery, attenuate the secondary scattered radiation (30~150keV) generated by the C-arm by more than 99.5%, and strictly control the dose rate at the operating position to <2.5μSv/h

Infection control barrier

The antibacterial rate of the metal surface is >99.9% (ISO 22196 certification), and the smooth and non-porous structure prevents pathogen retention, meeting the GB 15982 operating room infection standard.

Human-machine collaborative safety

The electromagnetic shielding layer blocks interference with monitoring equipment; the gravity self-locking wheel brake system has a braking response of <0.5 seconds to prevent accidental displacement; the rounded corner anti-collision design protects medical staff and precision instruments.

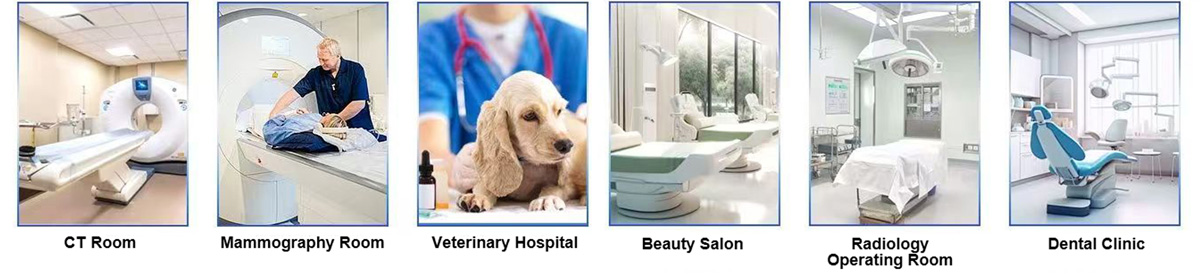

Typical application scenarios

Orthopedic navigation surgery: equipped with a 1.2m curved screen, fitted with the operating table to achieve surround protection, and the scattered radiation attenuation rate is 99.5%.

Cardiac interventional therapy: The dual folding screen unfolds to cover a 3.6㎡ protection area, reducing the operator's exposure dose by 98%.

Neurosurgery hybrid surgery: Expand the top protection plate (lead equivalent 3.0mmPb) to strengthen the key protection of the head and neck.

Deep customized service

Size adaptation: Width 800~2000mm (precisely designed according to the operating room channel), height 2000~2200mm (avoid laminar air supply outlet).

Functional expansion:

Integrated sterile instrument tray/lead clothing hanger system

Motor-driven remote control shift (load ≥ 50kg, movement accuracy ± 2cm)

Special reinforcement:

3.5mmPb lead equivalent window for neurosurgery

Pediatric surgical screen surface covered with EN71-3 certified cartoon antibacterial coating

Summary: This product is a mobile radiation barrier with dynamic protection during surgery as the core, integrating infection control and human-machine safety. It solves the scattered radiation isolation needs of orthopedic, interventional and other surgeries through modular customization, and builds a compliant protection closed loop for complex operating rooms.