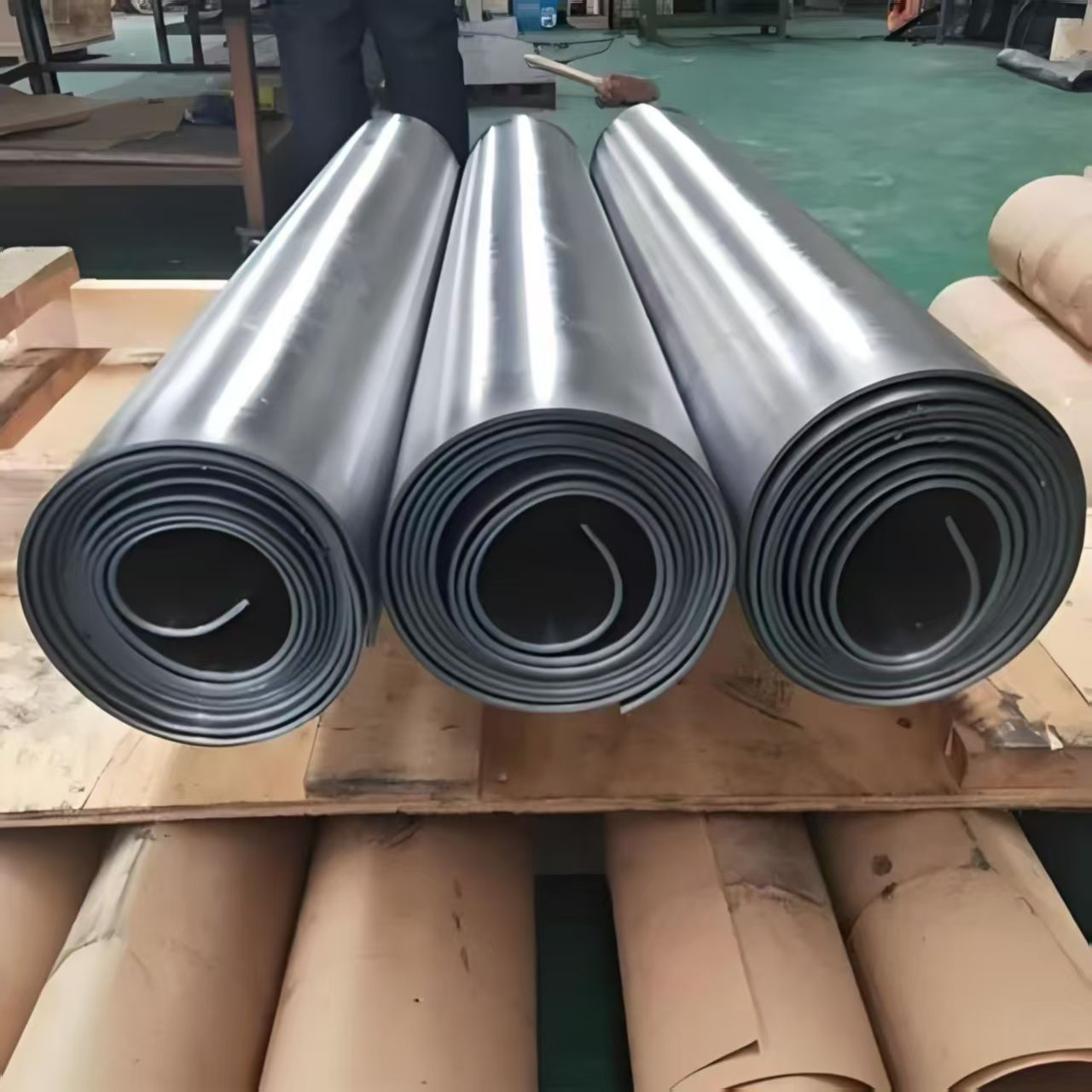

Lead Coil Lead Sheet

Absolute protection: density up to 11.34g/cm³, X/γ-ray shielding rate> 99% (especially good at high-energy rays above 300kV), lead equivalent accurate 1:1.

Ultra-thin and space-saving: 1-3mm thickness can meet the protection requirements, greatly saving the effective building area.

Flexible and easy to construct: can be bent and cut, fit complex structures (pipeline/equipment wrapping), support welding and sealing without leakage.

Stable and durable: corrosion-resistant, non-aging, service life of more than 30 years, maintenance cost close to zero.

High cost performance: low unit protection cost, 100% recyclable waste lead

Lead coils and lead plates are ultra-high-density protective materials rolled from electrolytic lead with a purity of ≥99.99%. With an absolute density advantage of 11.34g/cm³ and the physical properties of atomic number 82, they have become the industry gold standard for shielding high-energy X/γ rays and neutron flows. They are especially suitable for scenarios such as nuclear industry and medical radiotherapy that have extremely strict requirements on space efficiency and protection level.

1. Core product features

Ultimate protection performance

Full spectrum coverage: The shielding rate of 10keV-10MeV rays (including 6-15MV high-energy γ rays for medical linear accelerators) is >99%, and 1mm thickness is equivalent to 1mmPb lead.

Neutron protection extension: Neutron radiation can be efficiently slowed down through the composite cadmium layer (key application in nuclear reactors).

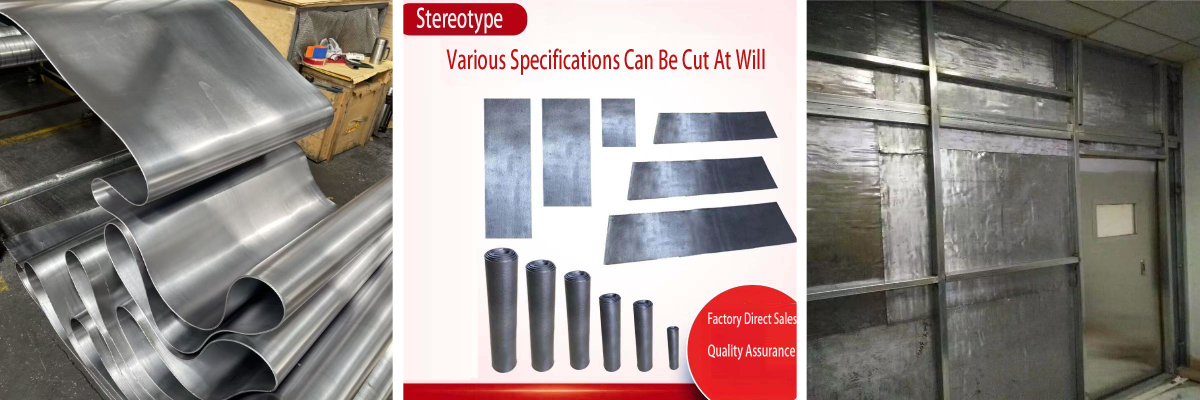

Morphological adaptation advantages

Lead plate (rigidity): high flatness (±0.1mm), suitable for planar structures such as walls and protective doors, and thickness 1-50mm can be customized.

Lead coil (flexible): bendable and winding (minimum curvature radius ≥ 5 times thickness), specially used for pipes, equipment wrapping and curved buildings (such as curved CT rooms), conventional thickness 0.5-5mm.

Hundred-year durability

Acid and alkali corrosion resistance (epoxy resin can be plated on the surface), stable performance at -50℃~150℃, service life > 50 years.

100% recycling and reuse, long-term cost is lower than composite materials.

2. Core application scenarios

Medical field

Rigid lead plate: radiotherapy room wall (2-3mm), CT machine protective fence (sealed with lead tape at seams).

Flexible lead coil: C-arm wrapping of angiography machine, mobile lead screen skeleton cladding (1.5mm coil).

Nuclear industry field

Lead lining of nuclear waste container (50mm composite plate), reactor neutron moderator (lead-cadmium composite plate).

Hot chamber observation window (step-jointed lead glass + lead plate), spent fuel transport channel (lead coil wrapped weld).

Industrial and civil

Industrial flaw detection room shield (3-10mm lead plate), radon-proof basement wall (0.5-1mm lead coil attached).

Data center electromagnetic shielding layer (ceiling lead plate ceiling), scientific research laboratory beam line protection (99.995% high purity lead).

3. Technical parameters and construction points

Key parameters

Purity: ≥99.99% (GB/T 1470-2020 standard, medical ≥99.994%)

Density: 11.34g/cm³ (20℃)

Lead roll specifications: thickness 0.5-5mm x width ≤1500mm x roll length customization

Lead plate specifications: thickness 1-50mm x 1000×2000mm (standard plate)

Professional construction specifications

Plane installation (lead plate):

Keel base fixed, staggered paving, lead plate nails + lead tape double sealing seams.

Door and window openings are stepped (overlap ≥100mm), and pipeline penetrations are filled with lead sleeves + lead putty.

Curved surface construction (lead roll):

Directly wrap the pipeline/equipment, and the longitudinal seams are cold-pressed welded + covered with lead tape.

The curved wall is glued with adhesive backing, and the joints are reinforced with pressure strips.

Surface protection: Cover with gypsum board or apply protective paint to avoid mechanical damage.

Safety warning

Forced ventilation during cutting/welding, operators wear lead dust protection equipment (EN 149 certified masks).

Waste materials must be handed over to licensed recyclers for disposal, and ordinary landfill is strictly prohibited.

Industry value summary: Lead coils and lead sheets continue to be the cornerstone of industrial protection in cutting-edge fields such as nuclear power and radiotherapy with their irreplaceable protection limits, space revolution and cross-century stability.