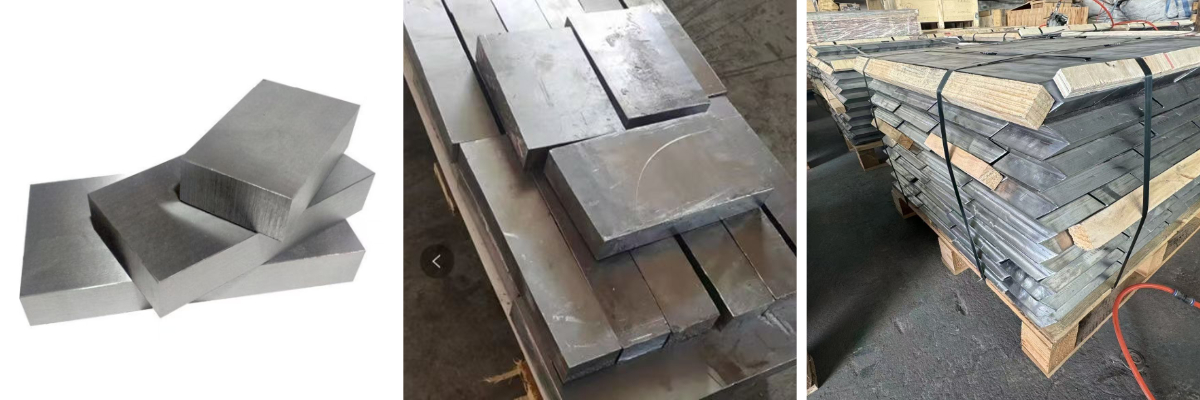

Radiation Proof Lead Brick

Extreme shielding: density 11.34g/cm³, 100mm thick blocks more than 90% of 100kV X-rays, gamma ray attenuation rate is 3 times higher than concrete

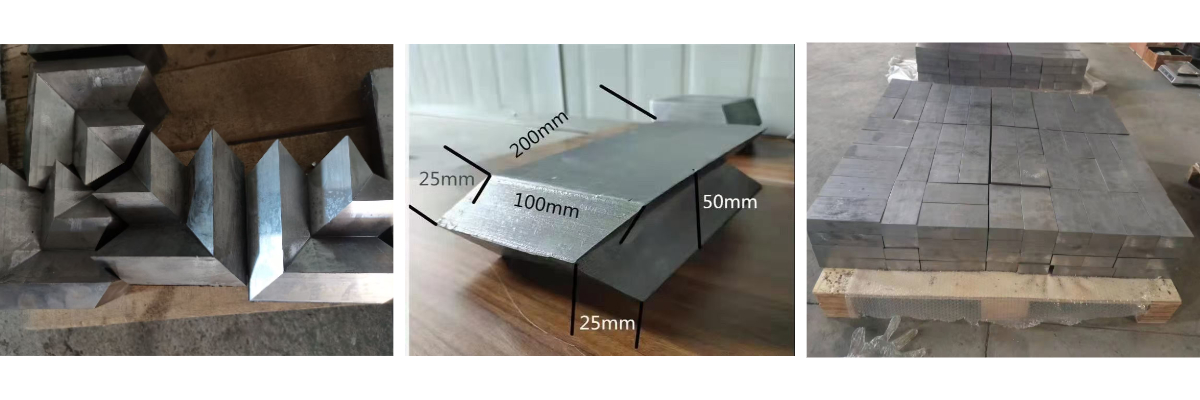

Zero leakage structure: bite design achieves ≤0.5mm gap, radiation leakage is reduced by 22.7dB (0.15MeV measured)

Permanent protection: corrosion and aging resistance, 50 years maintenance-free, life expectancy exceeds traditional masonry by 40%

Efficient and economical: modular assembly speeds up by 400%, wall thinning by 20% to save lead, recovery rate>98%

Dynamic stability: resistant to 8-magnitude earthquake, 10-meter high wall deformation <1.5mm, ship nuclear compartment verification

The radiation-proof lead bricks are made of ≥99.99% high-purity electrolytic lead (in compliance with GB/T 1470-2021 standards), vacuum smelted to remove impurities, and high-pressure cast. The density reaches 11.34±0.03g/cm³ (measured to be 3.4 times that of concrete), laying the physical foundation for radiation shielding. The product adopts a mortise and tenon joint structure design, and the edge is precisely processed into a trapezoidal/dovetail groove shape. After assembly, the gap is ≤0.5mm, and the shear strength is ≥15MPa, which completely solves the hidden danger of radiation scattering.

Core Performance

1. Radiation Shielding Effectiveness

X/γ-ray protection: 100mm thickness can attenuate 100kV-level X-rays>90%, and 150mm wall meets the GBZ 130-2020 medical protection standard (2.5mm lead equivalent).

Neutron shielding: Adding a boron/polyethylene composite layer, the 1MeV neutron absorption rate is increased to 99.5%.

Leakage control: The bite structure reduces the γ-ray leakage by 22.7dB (0.15MeV measured).

2. Endurance in extreme environments

Temperature span: -50℃ extreme cold to 150℃ hot room environment performance without attenuation (verified by nuclear power plants).

Corrosion resistance: Tolerant to pH 3-11 acid and alkali corrosion, annual surface oxidation <0.01mm.

Ultra-long life: Nano-grain boundary strengthening technology ensures 50 years of maintenance-free (creep resistance increased by 50%).

3. Engineering value breakthrough

Construction efficiency: The modular assembly speed reaches 25㎡/person/day, which is 400% higher than traditional masonry.

Comprehensive cost reduction: The bite design reduces the wall thickness by 20%, reduces the lead consumption by 35% + maintenance cost by 90%.

Dynamic stability: Through the 9-magnitude earthquake simulation, the deformation of the 10-meter-high wall is <1.5mm (verified by the nuclear compartment of the ship).

Core application scenarios

▶ Medical and health field

Radiology protection: PET-CT room (150mm interlocking brick wall, 0.25mm lead equivalent), linear accelerator treatment room neutron shielding layer.

Mobile protection system: interventional operating room lead screen (0.5mm lead equivalent real-time shielding), nuclear pharmacy molybdenum-99 storage and transportation wall (leakage <1μSv/h).

▶ Nuclear energy industry

Reactor neutron moderator (boron brick + cadmium interlayer, absorption rate 99.8%), spent fuel pool double-wall enclosure structure, post-processing plant nitric acid vapor corrosion-resistant wall (annual corrosion rate <0.1mm).

▶ High-end manufacturing and scientific research

Industrial CT 360° curved protection cabin (R≥1.5m customized), isotope battery shielding (weight accuracy ±0.01g/cm³), synchrotron radiation source anti-micro-vibration tunnel.

Quality and safety assurance

Authoritative certification: passed ISO 14126 compression certification (≥28MPa), IAEA RS-G-1.6 radiation safety standard, China Nuclear Power Institute leakage detection (<2.5μSv/h).

Operation specification: Wear lead-proof gloves and masks during construction, storage environment humidity ≤70% (to prevent white rust formation), professional recycling rate of scrapped lead bricks>98%.

Radiation-proof lead bricks are a trinity of density foundation + structural innovation + process breakthrough, becoming the cornerstone guarantee for the safe use of nuclear technology by mankind.