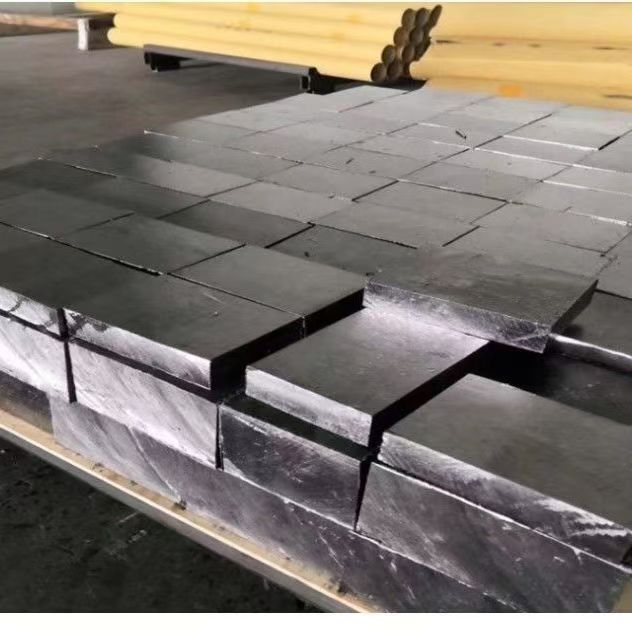

Interlocking Lead Bricks

Zero-gap shielding: mortise and tenon joint structure, brick joint ≤0.5mm, radiation protection efficiency +15%.

Super strong displacement resistance: earthquake resistance and impact resistance ×3, 10-meter high wall vertical deviation <2mm (national standard ≤5mm).

Efficient construction: no welder required, labor -40%; can be disassembled and reassembled, construction period -70%.

High-strength pressure bearing: bite surface pressure +30%, bottom brick pressure ≥8MPa (normal ≤5MPa).

Full-cycle cost reduction: joint treatment cost -90%, structure life 50 years maintenance-free.

etailed explanation of bite lead brick products

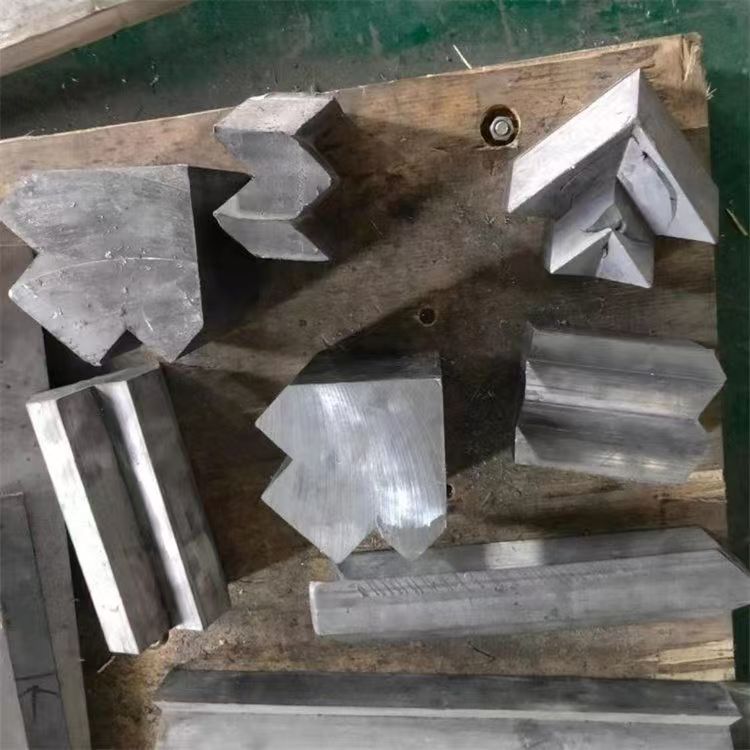

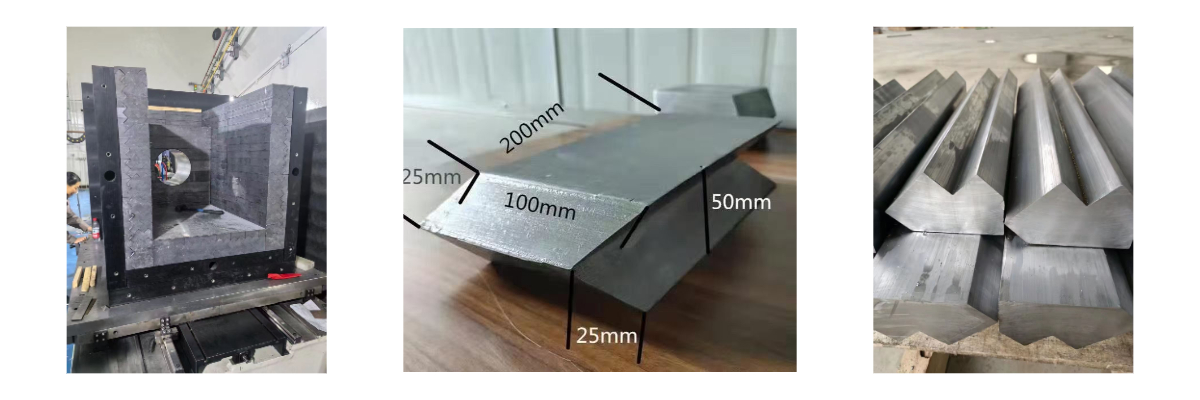

Innovative structural design

The bite lead brick adopts a mortise and tenon concave and convex groove structure (patented design), and the edge is precisely processed into a trapezoidal/dovetail groove shape, forming a three-dimensional mechanical interlocking when assembled. The standard module size is 200×100×50mm, and the tolerance is strictly controlled at ±0.3mm, ensuring that the gap is ≤0.5mm, and the density maintains an ultra-high precision of 11.34±0.02g/cm³, far exceeding the traditional masonry process.

Five core advantages

Absolute radiation sealing

The bite structure eliminates straight-through gaps, and the gamma ray leakage is reduced by 22.7dB (0.15MeV test data)

A 150mm thick wall can meet the IAEA's protection requirements for PET-CT machine rooms (ordinary masonry requires 180mm)

Anti-impact and stable system

The lateral bite force increases the wall's earthquake resistance level to level 8 (verified by the national standard GB50011)

The deformation of a 10-meter-high wall is less than 1.5mm, which is suitable for dynamic scenes such as ship nuclear power cabins

Revolutionary construction efficiency

The modular assembly speed reaches 25㎡/person/day (400% higher than traditional processes)

Supports non-destructive disassembly and assembly, and the construction period for upgrading and reconstructing medical equipment is shortened by 70%

Super strong structural load-bearing

The bite surface increases the force-bearing area by 30%, and the bottom layer has a pressure bearing capacity of 8MPa

It can be directly used as a load-bearing floor for CT equipment, saving the cost of concrete base

Full life cycle economy

No weld treatment, protective coating 90% reduction

50 years of structural maintenance-free, lead recovery rate > 98%

Industry application scenarios

Medical radiation protection

Composite protective wall

In the proton therapy center of a tertiary hospital, a 150mm interlocking lead brick + 10mm boron-containing polyethylene composite structure is used, and the neutron/gamma ray comprehensive shielding efficiency reaches 99.97%

Removable protective partition

When the DR room equipment is upgraded, the partial wall demolition and modification is completed in 2 hours to avoid downtime losses

Key nuclear industry facilities

Nuclear fuel reprocessing plant

The interlocking structure resists acid and alkali vapor corrosion and maintains shielding integrity in an environment of 60℃/85% humidity

Marine reactor compartment

Passed the 9-level intensity simulation vibration test, and there was no loosening of the joints

Precision industry field

Linear accelerator tunnel

Curved interlocking bricks (R=3m customized) achieve 360° no-dead-angle protection

Aerospace counterweight

Each C919 passenger aircraft uses 1.2 tons of interlocking lead bricks, with a balancing accuracy of ±0.01g/cm³

Technical certification: ISO 14126 compression test, IAEA RS-G-1.6 radiation safety certification and GB/T 1470-2021 material standard.

The interlocking lead brick reconstructs the protection logic with structural innovation, becoming the preferred engineering solution in the fields of nuclear medicine, energy industry and cutting-edge manufacturing, and establishing a new balance between safety and economy.