Clean Room Industrial Door

The clean room door is made of high-specification stainless steel or coated steel plate, which is corrosion-resistant and disinfection-resistant, with no dead corners on the surface and easy to clean; the airtight structure is matched with medical sealing strips and an automatic lifting bottom frame to dynamically block particulate microorganisms, and the pressure difference control accuracy reaches ±1Pa. It supports induction opening and closing, electronic interlocking to avoid cross contamination; it integrates customized modules such as HEPA filtration, explosion-proof and fireproof, and is suitable for different cleanliness levels. The modular design is easy to maintain, complies with GMP/FDA certification, takes into account both safety and compliance, and is the core barrier to ensure the efficient operation of the clean environment.

Industrial clean room doors are designed for harsh environments such as electronic manufacturing, semiconductors, and precision machinery. They are centered around high strength, high sealing, and flexible customization, meeting ISO 14644 cleanliness levels and industrial safety standards. The core advantages and configurations are as follows:

Material and structure

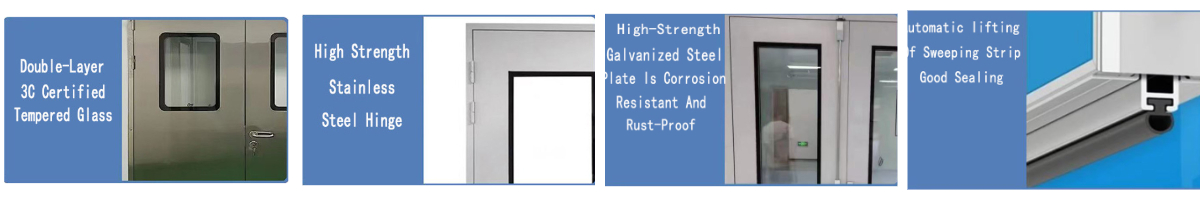

Main material: 304 stainless steel or galvanized steel plate substrate, surface treated with electrostatic spraying or lamination, corrosion-resistant and wear-resistant, customizable in matte gray, light blue, white and other colors to match the overall factory environment;

Airtight design: Door frames and door panels are embedded with silicone/EPDM double-layer sealing strips, and the bottom is equipped with an automatic lifting and clamping device (inflatable or mechanical), airtightness meets ISO Class 5-8 standards, differential pressure control accuracy ±1.5Pa, effectively isolating dust, oil mist and particulate pollutants.

Flexible size customization

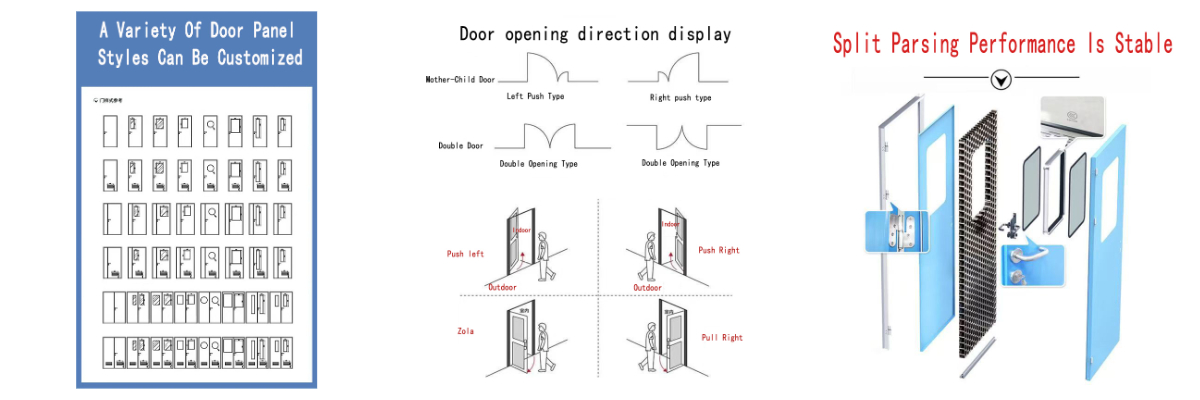

Supports non-standard size customization, door opening width range 800-3000mm, height 2000-4500mm, thickness 40-100mm, adapting to the requirements of ultra-wide logistics channels or special equipment entry and exit;

Single-opening, double-opening, sliding or fast rolling shutter door structure can be customized, and special-shaped door body (arc angle, with observation window, etc.) can also be designed on demand to meet complex space layout.

Functional configuration

Intelligent control: standard radar/photoelectric sensor switch, card swipe or button start, optional PLC linkage system, and clean room air conditioning, air shower equipment to work together;

Safety protection: electronic/mechanical interlocking prevents double doors from opening at the same time, explosion-proof door body complies with ATEX standards, fireproof door fire resistance limit of 60-90 minutes (EN 13501 certification), anti-static door surface resistance ≤10^6Ω;

Cleanliness enhancement: the door body can be integrated with HEPA filter air supply unit or air curtain isolation system to reduce the risk of cross contamination.

Installation and maintenance

Modular component design supports quick disassembly and partial replacement, and the maintenance cost of vulnerable parts such as sealing strips and drive motors is low;

Adapt to various walls such as color steel plates, concrete, steel structures, etc., provide embedded or external installation solutions, and the pre-compression technology of sealing strips ensures long-term airtight stability.

Application scenarios

Widely used in chip workshops (anti-static), automobile painting lines (explosion-proof), food factories (corrosion-resistant), pharmaceutical warehouses (fireproof) and other scenarios. The color and logo can be customized according to the corporate VI to enhance the overall aesthetics and brand recognition.

Certification and service

Passed ISO 9001/14001 system certification, in line with GB 50073 clean workshop design specifications, provide 3-year warranty and lifelong technical support, support drawing deepening and on-site measurement, and ensure that the delivery accurately matches customer needs.