Lead Glass X Ray Protection

High-efficiency shielding: high lead oxide (PbO) content, density exceeding ordinary glass, lead equivalent quantitative protection (10mm thickness ≈ 2.0mmPb), strong absorption of X-rays.

Clear perspective: high transmittance and low chromatic aberration, support real-time observation equipment (such as CT room), taking into account safety and precise operation.

Stable and durable: high hardness and impact resistance, weather resistance and corrosion resistance, long-lasting performance, suitable for the harsh environment of medical/nuclear industry.

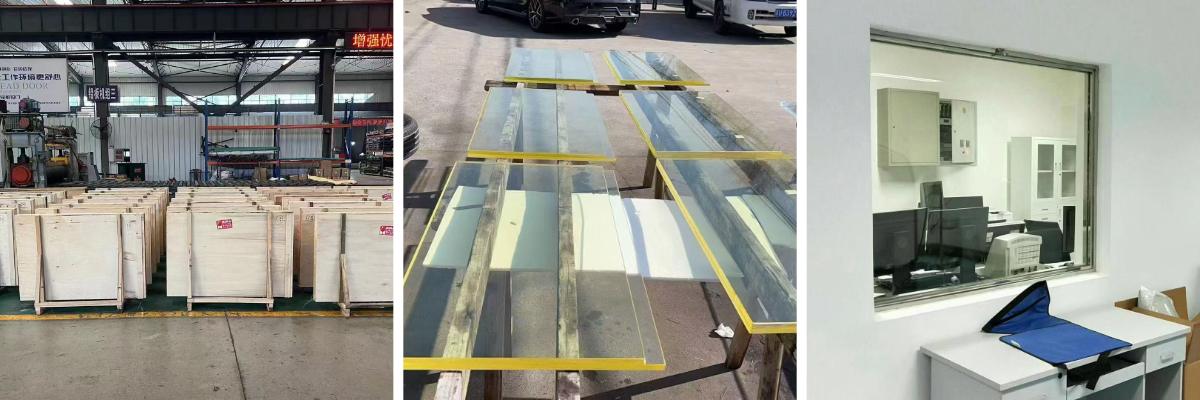

Lead glass, also known as radiation-proof glass or X-ray shielding glass, is a special optical glass containing a high proportion of lead oxide (PbO). With its excellent radiation shielding ability, it has become an indispensable safety protection material in the fields of medical treatment, nuclear industry, security inspection and scientific research, and plays a key role in ensuring personnel safety and accurate operation of equipment.

Core characteristics and advantages

Excellent radiation shielding performance

Core value: The core advantage of lead glass lies in its efficient shielding ability against harmful ionizing radiation such as X-rays and gamma rays.

Lead equivalent: The shielding ability is accurately quantified in "lead equivalent" (unit: mmPb), indicating that a certain thickness of lead glass is equivalent to the protective effect of a pure lead plate in millimeters (for example: a certain type of glass with a thickness of 10mm can reach 2.0mmPb). The higher the lead equivalent, the stronger the protection level.

Protection principle: High-density lead elements can effectively absorb and attenuate radiation energy, significantly reduce the radiation dose rate, and provide a safety barrier for people behind the observation window.

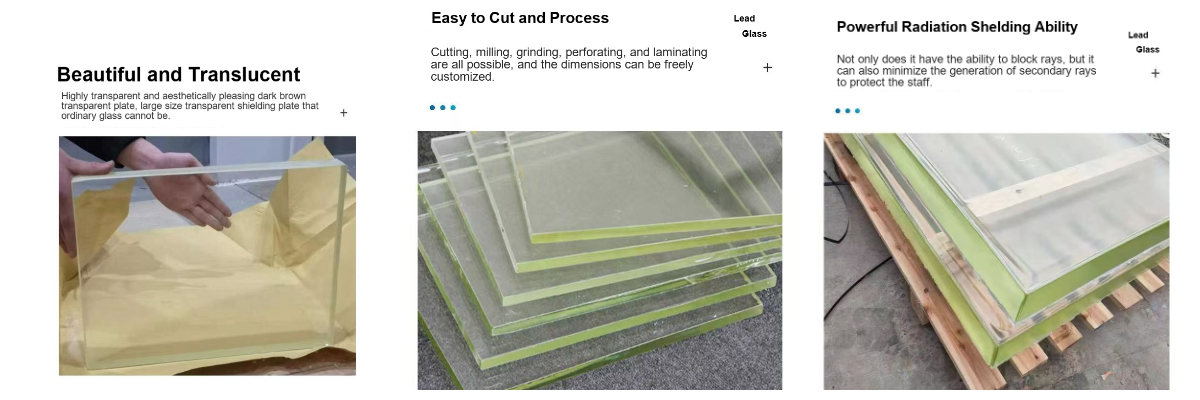

High transparency and excellent optical properties

Clear vision: While providing strong protection, lead glass maintains excellent optical transparency and low color difference (usually light yellow or light blue), ensuring that operators can clearly and undistortedly observe the internal conditions of the shielded area (such as medical imaging equipment operation, nuclear reactor monitoring, industrial flaw detection process).

Smooth surface: After fine polishing, the surface is flat and has excellent light transmittance.

Excellent physical and chemical stability

High density and high hardness: The lead component gives it a density and hardness far higher than ordinary glass, and the structure is sturdy and durable.

Strong weather resistance: It has good tolerance to humid air, ultraviolet rays and general chemicals, and has a long service life.

High temperature resistance: It has certain heat resistance and can adapt to various environmental requirements.

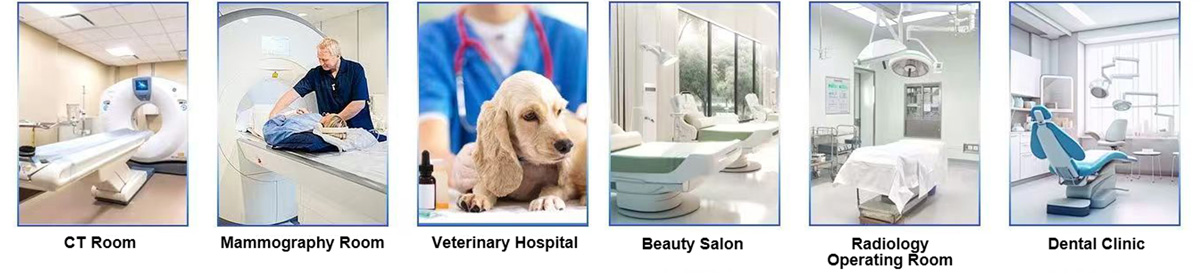

Key application areas

Medical health: Observation windows in CT scanning rooms, DR rooms, interventional operating rooms (DSA), X-ray rooms, PET-CT rooms, and radiotherapy control rooms; protective screens for dental X-ray equipment.

Nuclear energy and industry: Observation windows in nuclear power plant control rooms, nuclear fuel processing facilities, industrial flaw detection rooms (X-ray, gamma ray), and isotope laboratories.

Security inspection and protection: Observation windows for X-ray security equipment in airports, stations, and important venues.

Scientific research experiments: Observation windows for various physical, chemical, and biological laboratories that require radiation shielding.

Product specifications and services

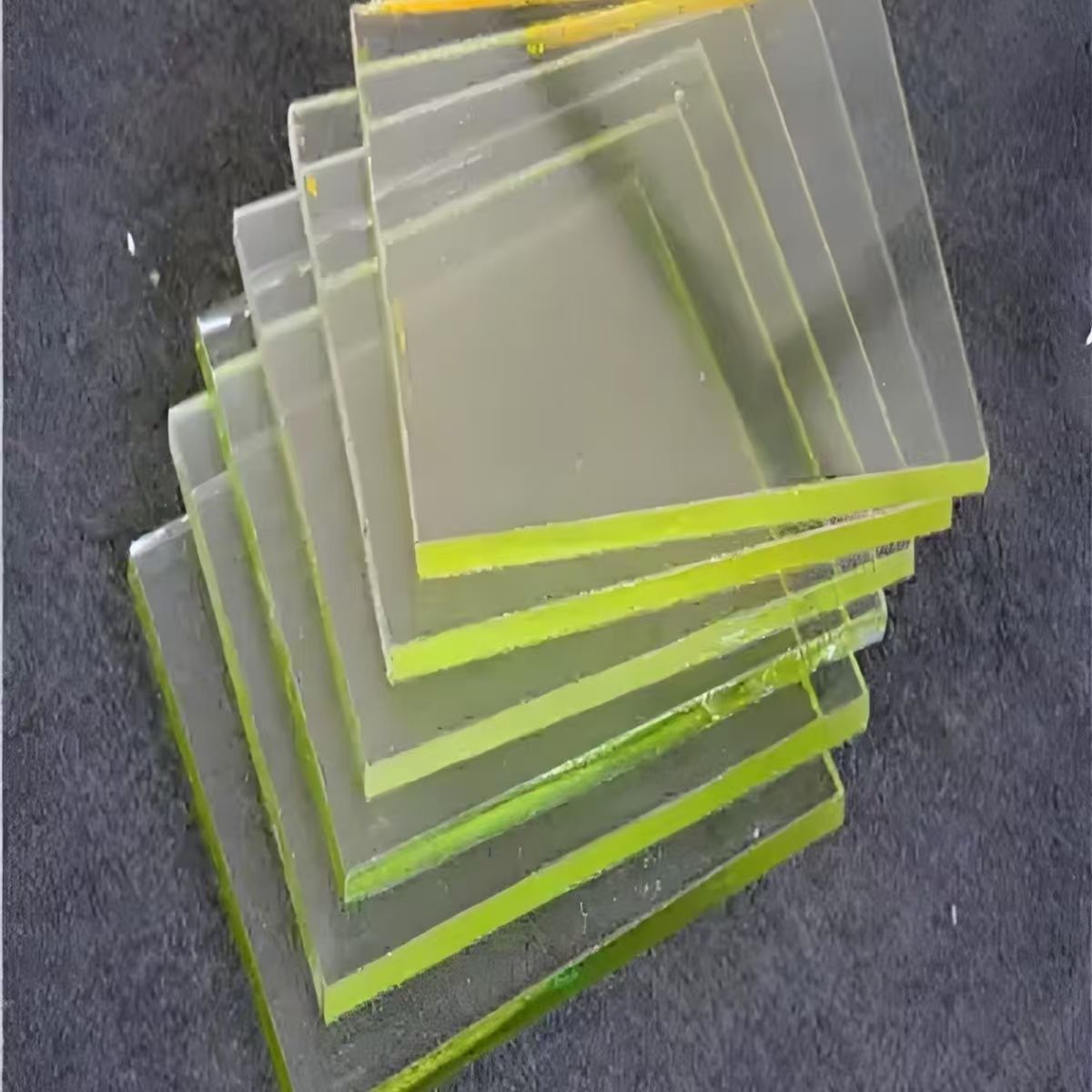

Wide range of thickness: Provide a variety of thickness specifications (such as: 5mm, 8mm, 10mm, 12mm, 15mm, 18mm, 20mm, etc.) to meet different protection levels (lead equivalent) requirements.

Flexible size customization: Support customized processing such as cutting, edging, drilling, and chamfering according to the user's actual installation location and observation needs.

Various installation methods: Can be embedded in the wall, lead protection door or installed in a special frame for use, and provide supporting installation solution recommendations.

Reasons for choosing lead glass

Lead glass is a solution that perfectly combines safety, reliability and visibility. Choosing high-quality lead glass means building a visible safety line for operators in high-risk working environments, ensuring that while effectively shielding harmful radiation, a clear operating field of vision and work efficiency are maintained. It is an indispensable professional-grade protective material in the fields of medical diagnosis, nuclear technology application, industrial testing and cutting-edge scientific research.

Guarding safety and clear perspective - lead glass, your professional radiation protection eye.