X Ray Lead Glass Suppliers

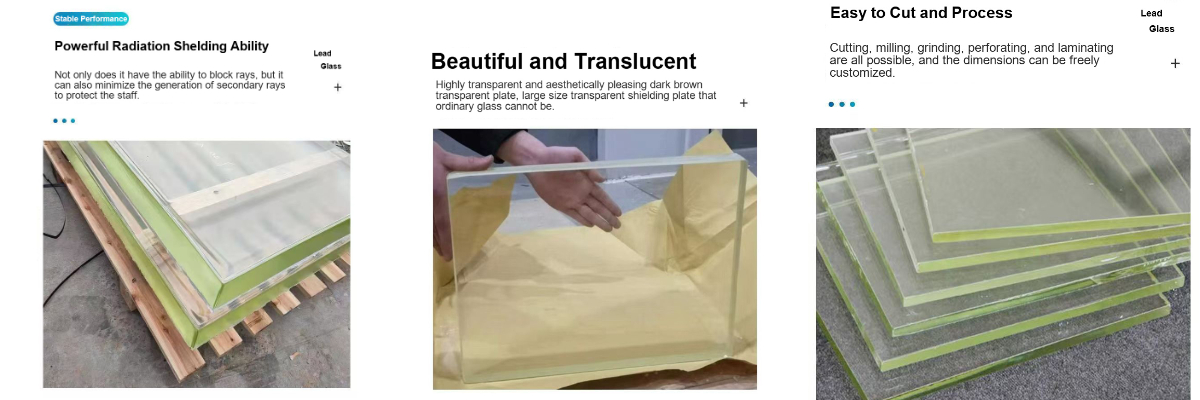

High lead shielding (20%-70% lead)

Density ≥4.8g/cm³, 0.5mm thickness can attenuate 90% of low-energy X/γ rays

Visual transparency

Light transmittance>85%, supports real-time observation of surgery/operation (such as interventional surgery window, CT control room)

Strong physical stability

Acid and alkali resistance/aging resistance/Mohs hardness ≥4, eliminate yellowing and fogging

Flexible customization

Curved surface/multi-layer composite structure (lead glass + explosion-proof glass), suitable for DR protective screen, nuclear medicine dispensing cover, etc.

X RayLead glass achieves excellent shielding performance through high content of lead oxide (20%-70%), with a density of 4.8-6.2g/cm³, about twice that of ordinary glass. Its protection principle relies on the photoelectric effect and Compton scattering of lead atoms, and the shielding rate of low-energy X/γ rays (≤100kV) exceeds 90% (5mm thickness). At the same time, it has excellent optical properties: light transmittance>85%, visible light distortion rate<5%, and anti-reflection film can be coated on the surface to reduce glare, so as to achieve distortion-free real-time observation in radiation environment.

Key application scenarios and technical solutions

Interventional operating room observation window: 15-20mm thick embedded lead glass wall is used, and the shielding efficiency of 120kV scattered radiation is ≥99%.

CT/MRI control room: curved lead glass window (lead equivalent 0.5-1.0mmPb) meets the national control room protection standard (GBZ 130-2020).

Nuclear medicine dispensing workstation: The lead glass protective cover integrates the manipulator operation hole to control the surface dose rate to <2μSv/h, effectively isolating β/γ rays.

DR mobile protection: The liftable lead glass screen (standard size 60×120cm) reduces the radiation of the operating position by 90%.

Pet radiotherapy: Multi-layer laminated explosion-proof lead glass cabin door, taking into account animal behavior observation and safety protection.

Advanced manufacturing process

Melting and casting process: Lead oxide and silicate are melted in a vacuum environment at 1200℃ to eliminate bubbles and ensure uniform composition.

Strengthening treatment: The surface toughening is increased to Mohs 4.5 hardness, and the polyurethane coating is superimposed to enhance the scratch resistance.

Composite design:

Sandwich structure: Lead glass and polyethylene explosion-proof layer are composited, with impact resistance >50J.

Curved surface molding: The arc of ≤150° is achieved through the hot bending process, which is suitable for the needs of curved observation windows such as DSA operating rooms.

Advantages compared to traditional protective materials

Visibility breakthrough: Solve the pain point of concrete/lead plate completely blocking the field of vision and realize direct monitoring of the operation area.

Space efficiency: The thickness is 60% less than that of concrete wall under the same protection, saving medical space.

Flexible installation: Supports multiple installation methods such as embedded, mobile, and hanging, and the convenience of transformation is far better than fixed lead plate.

Long-term economic efficiency: Lifespan> 20 years and maintenance-free, while lead plate needs regular anti-oxidation treatment.

Usage and maintenance specifications

Cleaning requirements: Hydrofluoric acid and strong alkaline cleaners are prohibited to avoid corrosion of glass network structure. Neutral solution is recommended for wiping.

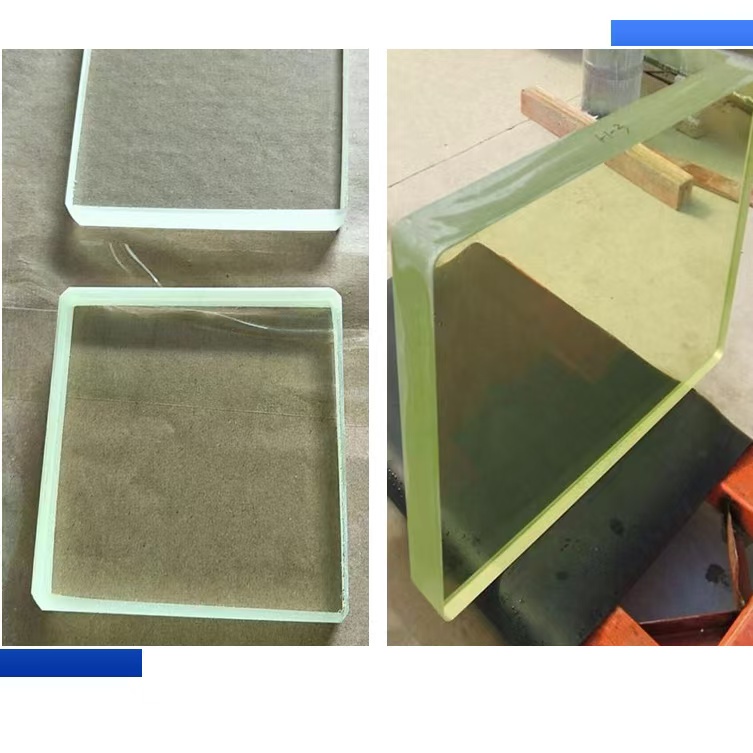

Anti-damage measures: Wooden frames are required to fix the corners during transportation and installation to prevent micro cracks caused by collision.

Performance monitoring: Detect shielding attenuation rate and light transmittance every 2 years. If the light transmittance drops by> 10%, it needs to be replaced.

Summary: Lead glass takes "transparent protection" as the core breakthrough, deeply integrating radiation shielding and real-time observation functions. Its high customization (thickness/curvature/composite structure), physical stability and long life cycle make it an irreplaceable protective component in high-risk scenarios such as modern radiation diagnosis and treatment and the nuclear industry, significantly improving operational safety and work efficiency.