Lead Lined Sliding Doors

Superior Protective Performance: Effectively blocks ionizing radiation such as X-rays and gamma rays, meeting stringent radiation shielding requirements.

Practical and Space-Saving: Thinner and lighter than other protective materials at the same level of protection, reducing space requirements.

Durable and Easy to Maintain: Stable performance, resistant to aging, long service life, and relatively simple installation and routine maintenance.

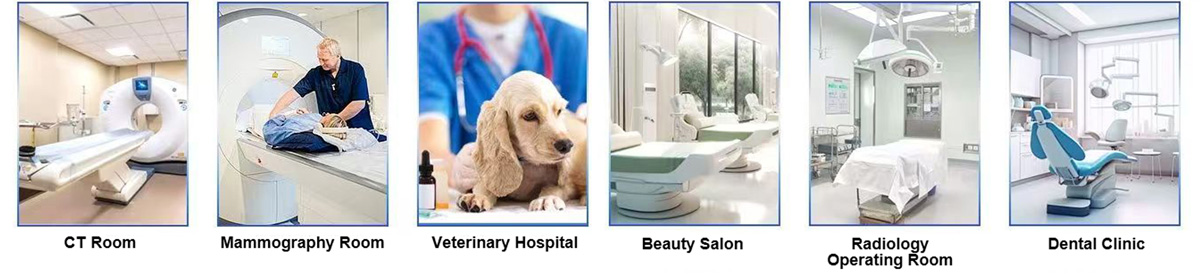

Wide Range of Applications: Suitable for locations with high radiation shielding requirements, such as hospital radiology departments, nuclear power plants, and industrial non-destructive testing departments.

Lead doors are specialized protective doors designed to effectively shield against ionizing radiation (such as X-rays, gamma rays, and neutrons). Their core value lies in providing a reliable safety barrier in high-risk radiation environments such as medical, industrial, and scientific research, protecting personnel from harmful radiation.

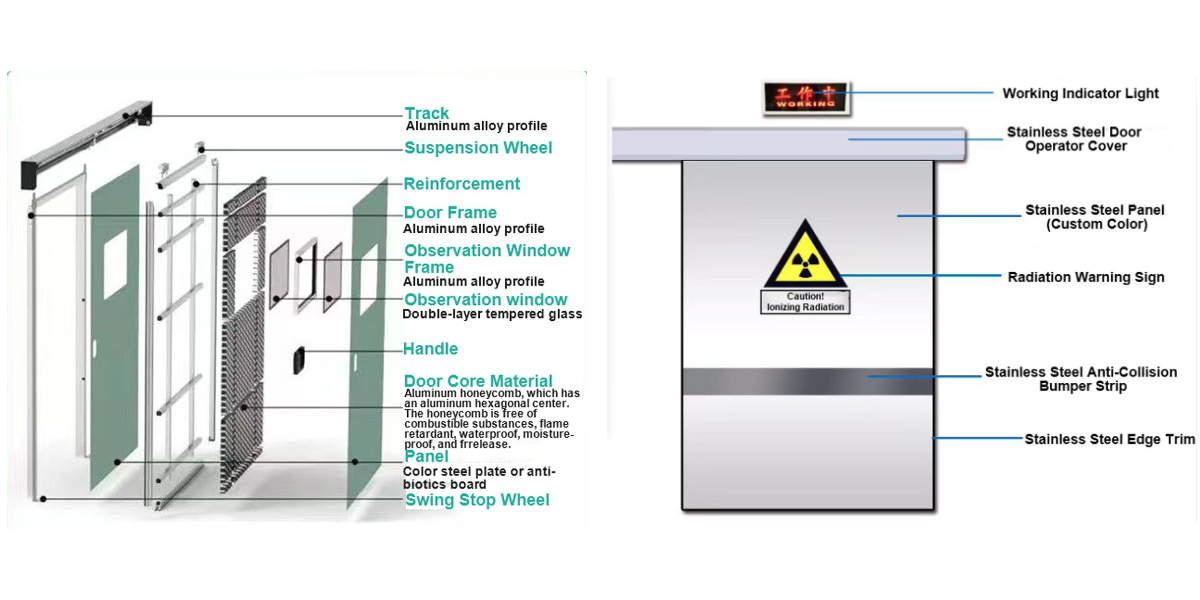

I. Structural Components

The lead door's structural design is sophisticated and robust, typically consisting of the following key components:

Door Frame: A rigid skeleton welded or assembled from high-strength steel (such as high-quality cold-rolled steel or carbon steel) provides overall support and strength.

Lead Shield: This is the core protective layer. High-purity (typically ≥99.99%) lead sheets are tightly wrapped or embedded within the door frame. The thickness of the lead sheets is strictly calculated and customized based on the required protection level (lead equivalent, measured in mmPb), ranging from a few millimeters to tens of millimeters or even thicker. The lead sheets must be laid seamlessly or overlapped to ensure no gaps for radiation leakage.

Surface cladding: Covering the exterior of the lead layer, typically stainless steel (such as 304 or 316, corrosion-resistant and easy-to-clean), plastic-coated steel, or fireproof panels provide an aesthetically pleasing, durable, and easy-to-clean surface while protecting the internal lead layer.

Door frame: Securely connected to the wall, typically made of steel, with lead sheets of corresponding thickness embedded within. This creates a tight "maze-like" or "step-like" overlap with the edge of the door leaf, minimizing radiation leakage from the gap when the door is closed.

Sealing system: Specialized radiation-shielding sealing strips (such as silicone or EPDM) are installed at the contact edge between the door leaf and the frame to further eliminate gaps and enhance shielding effectiveness.

Hardware:

Hinges: Heavy-duty, load-bearing hinges (such as pressure-bearing hinges or heavy-duty exposed hinges) are used, often made of stainless steel, to ensure smooth opening and closing of the door leaf and withstand significant weight.

Locking: Equipped with multi-point locking or interlocking locks (such as floor latches or central locking points) to ensure even and tight compression of the door leaf against the door frame on all sides for an optimal seal. A safety interlock is typically included to prevent the radiation equipment from activating if the door is not securely closed.

Operating Device: Depending on weight and needs, it can be equipped with a power-assisted push rod, floor spring, or electric or pneumatic opening and closing device (such as a sliding door motor).

II. Core Material

Shielding Material: High-purity lead (Pb). Lead is an irreplaceable core material for radiation shielding due to its extremely high density (11.34 g/cm³), excellent radiation attenuation (especially for X-rays and gamma rays), good processability, relatively low cost, and chemical stability.

Structural and Surface Materials:

Steel: High-quality cold-rolled steel and carbon steel are used for frames and structural supports, providing strength and rigidity. Stainless steel (304/316) is commonly used for surface panels and hardware, providing corrosion resistance, aesthetics, and easy cleaning.

Filling Material (Optional): The internal cavity of the door is sometimes filled with fireproof, soundproof, or protective materials (such as fire-resistant rock wool or boron-polyethylene composite for neutron shielding).

Sealing Material: Aging-resistant, highly elastic rubber or silicone sealing strips.

III. Significant Advantages

Excellent Radiation Protection: The high-density lead layer effectively attenuates and absorbs ionizing radiation, reducing radiation levels to below safety standards. The protection effect is reliable and can be accurately calculated (using lead equivalent).

Efficient Space Utilization (Comparative Advantage): While achieving the same level of protection, lead doors require significantly less thickness than materials such as concrete, saving valuable building space and making them particularly suitable for space-constrained locations.

Sturdy and Durable Structure: The steel frame and high-quality hardware ensure the door's overall strength, stability, and long service life. Lead is chemically stable and resistant to corrosion and aging.

Excellent Sealing and Security: The precise overlap structure and highly elastic sealing strips ensure effective shielding of the door gap; multi-point locks and interlocking devices provide operational safety.

Diverse Surface Finishes for Easy Cleaning and Maintenance: Stainless steel or spray-coated plastic surfaces are smooth, corrosion-resistant, and contamination-resistant, making them particularly suitable for clean environments like medical facilities, simplifying daily cleaning and maintenance.

Strong Customization: Dimensions, lead equivalent, opening method (swinging, sliding), surface material, color, and lock configuration can all be highly customized to meet specific site protection requirements and environmental conditions.

IV. Main Application Scenarios

Lead doors are widely used in all areas where strict control of radiation leakage and ensuring personnel and environmental safety is crucial:

Medical: Hospital radiology departments (X-ray rooms, DR rooms, CT rooms, DSA catheterization rooms), radiotherapy centers (linear accelerator rooms, gamma knife rooms, afterloading rooms), nuclear medicine departments (PET-CT, SPECT-CT rooms, filling rooms, injection rooms), dental radiography rooms, etc.

Industrial: Industrial non-destructive testing rooms (X-ray and gamma ray inspection rooms), nuclear power plants (radioactive area corridors and equipment rooms), irradiation stations, and nuclear waste treatment facilities.

Research: Nuclear physics laboratories, radioactivity laboratories, particle accelerator facilities, and radioisotope laboratories in universities and research institutions.

Security: Shielded room entrances and exits in large cargo/vehicle security systems.

In short, lead doors are an indispensable and critical physical barrier in modern radiation protection systems. Their meticulously designed structure, core lead shielding material, outstanding protection advantages, and wide range of applications make them a solid line of defense for radiation safety operations.

Why choose our lead doors?

1. As experts in X-ray protection, we specialize in the research, development, and production of lead doors, dedicated to providing customers with products tailored to their individual needs. As a renowned supplier in this field, we prioritize maintaining our reputation for excellence.

2. We boast strong technical and management capabilities, including a comprehensive quality system and numerous authoritative certifications. Each lead door undergoes rigorous testing to ensure it meets the high expectations of global customers for performance.

3. Our lead doors are designed for broad applicability, meeting the protection needs of diverse scenarios. With the goal of contributing to industry advancement, we continuously optimize the quality and performance of our lead sheet materials by incorporating modern technology.

4. As a leading manufacturer, we offer competitive pricing. With years of experience in exporting and customizing lead doors, we understand the specific needs of local markets, and our service has earned widespread customer recognition.

5. We strive to provide high-quality service throughout the entire process, ensuring you have peace of mind when purchasing and using our lead doors. We prioritize talent development internally to ensure our team's professional expertise and provide a solid foundation for the quality and service of our lead door products.

6. We have always been customer-oriented, and strive to improve every aspect from research and development to service, just to make customers who choose our lead doors feel at ease and satisfied.

| FAQ |

Q: Do you offer OEM services?

A: We support custom production, manufactured to your exact specifications. Providing reference samples ensures a precise match.

Q: Can you accept small orders?

A: In-stock items can be shipped immediately; out-of-stock orders will be consolidated, requiring a reasonable turnaround time.

Q: Is there a sample fee? How is shipping handled?

A: Samples are available free of charge, and shipping costs will be deducted from the order amount after placing an order.

Q: How is the radiation protection performance of the product verified?

A: Each door undergoes professional testing before leaving the factory, and a third-party lead equivalent report is available.

Q: How is the order fulfillment process followed up?

A: After production begins, we regularly send photos of the actual product and videos of key processes for full transparency.

Q: Do you provide installation guidance or after-sales service?

A: We provide free remote installation guidance and operator training, as well as lifetime technical support.