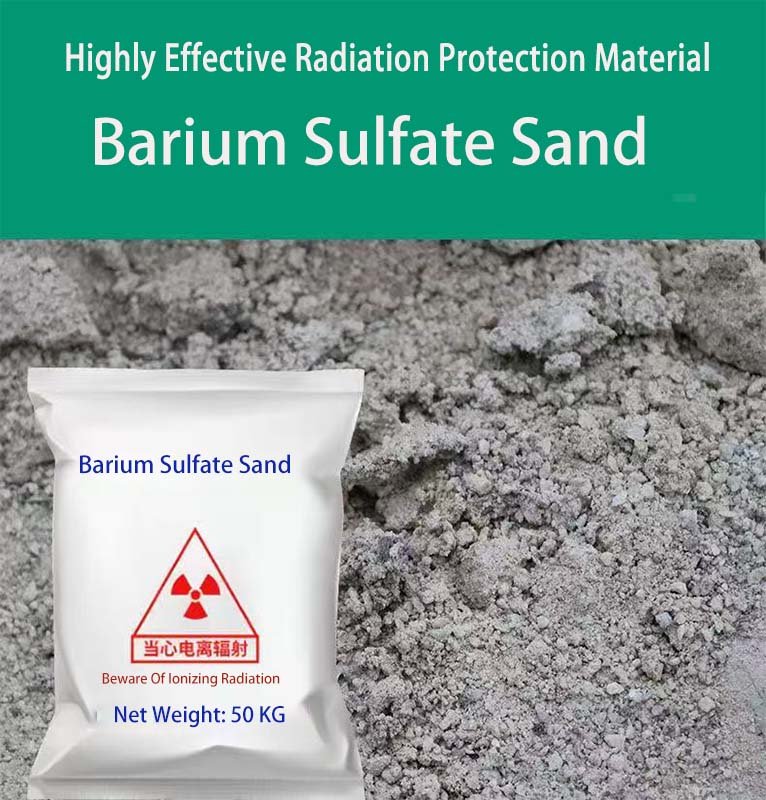

Medical Barium Sulfate Sand

on-toxic and environmentally friendly:

Natural barium sulfate (BaSO₄) has no heavy metal toxicity, no volatile pollution during construction, and meets medical environmental assessment standards.

High fluidity and density:

Graded sand with a particle size of 0.5-3mm, good pouring fluidity, no dead corners for filling walls/special-shaped structures, and a density of ≥2.8g/cm³.

Shielding cost-effectiveness:

A wall of 30% barium sand + cement (300mm thick) is equivalent to a 2mm lead plate, reducing costs by 50%.

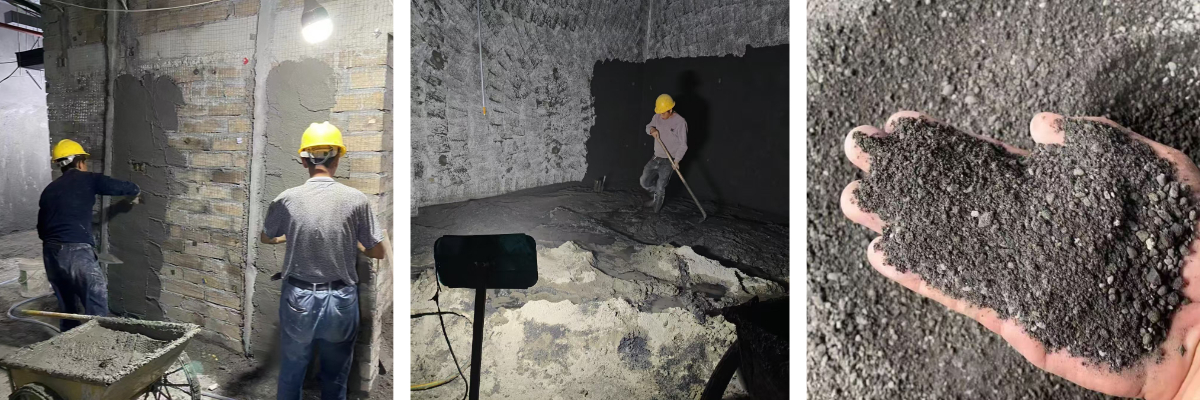

Convenient construction:

Directly replace part of the aggregate, pour simultaneously with cement, and shorten the construction period by 60% compared to lead plate installation.

Durable and crack-resistant:

Low hydration heat, hardening shrinkage rate <0.03%, and no radiation leakage cracks in the wall.

Barium Sulfate Sand Product Introduction

I. Core Performance

Shielding Effectiveness

High density of barium element (4.5g/cm³): Absorbs X-rays through the photoelectric effect, and the attenuation of 90kV X-rays by 250mm thick wall is >99% (equivalent to 1.5mm lead equivalent).

Uniform protection: The graded particle size (0.3-3mm) ensures that there are no pores in the casting, and the shielding uniformity is 40% higher than that of the lead plate.

Physical properties

Density 3.0-3.5g/cm³: Cold-pressed molding without pores, compressive strength ≥30MPa.

Slump ≥180mm: Self-leveling filling of special-shaped structures to eliminate construction dead corners.

Safe and environmentally friendly

No heavy metal pollution: natural barium sulfate (BaSO₄≥96%), lead content <0.001%, passed ISO 10993 biocompatibility certification.

Class A radioactivity certification: internal irradiation index ≤0.3 (national standard GB6566).

2. Five major application advantages

Cost reduction of 50%: Replace lead plate + steel structure, the cost is only 1/2

Construction period shortened by 60%: Directly mixed into concrete casting, 200㎡ machine room completed in 3 days

Long crack resistance life: Dry shrinkage rate <0.02%, no radiation leakage cracks in 30 years

Fireproof and moisture-proof: Melting point 1580℃, humidity 95% environmental performance unchanged

100% jointless: integral casting avoids the risk of lead plate splicing leakage

3. Key technical parameters

Proportion: barium sand: cement: quartz sand = 3.5:2:4.5 (weight ratio), water-cement ratio 0.42-0.45.

Construction specifications:

Layered casting (each layer ≤40cm), mechanical vibration compaction;

Corners/openings are thickened by 50% to prevent cracks;

Covering maintenance for 7 days + natural maintenance for 21 days.

Acceptance criteria: 150kV X-ray scanning, leakage dose <2.5μSv/h (GBZ130-2020).

IV. Typical application scenarios

Dental DR room:

250mm wall (equivalent to 1.5mm lead equivalent, 90kV), door frame pre-embedded barium sand reinforcement.

Orthopedic radiography room:

350mm floor (equivalent to 2.5mm lead equivalent, 150kV), compressive load ≥5kN/m².

CT equipment base:

Partial casting to replace lead plate (cost reduction of 40%), 1mm lead sheet is required to prevent 140kV scattered rays.

Limitation tips: Only applicable to ≤150kV medium and low energy rays, high energy scenes (such as PET-CT) need to use boron-containing concrete or lead plate instead.

V. Economic comparison

Compared with the lead plate solution: save 50% cost and reduce steel structure support.

Compared with ordinary concrete: the protection efficiency is improved by 300%, and the thickness is reduced by 40%.

Upgrade plan: For scenes above 150kV, a composite structure of barium sand + 0.5mm lead sheet is used, and the cost is still 35% lower.