Double Leaf Lead Doors

Radiation Protection: Reliable shielding for CT, DR, and X-ray rooms.

Seamless Frame: Interlocking design for a smooth finish.

Enhanced Core: Eco-friendly aluminum honeycomb for sound and thermal insulation.

Durable Build: High-quality steel or stainless steel with No.1 lead sheets.

Fire-Resistant: Offers long-term performance and fire protection.

Premium Finish: AkzoNobel paint and Anheng hardware for security and style.

Product Introduction

Double-leaf lead doors, also known as double-leaf radiation protection lead doors, are specialized shielding doors designed to block and absorb radiation such as X-rays. Leveraging the dense atomic structure of lead—which resists damage from radiation better than metals like gold, copper, or iron—these doors provide superior radiation protection.

When X-rays encounter thick lead panels, scattering occurs. Double-leaf lead doors are constructed with two heavy lead plates separated by a narrow gap, forming an open structure that produces opposing shadow images to effectively minimize radiation leakage.

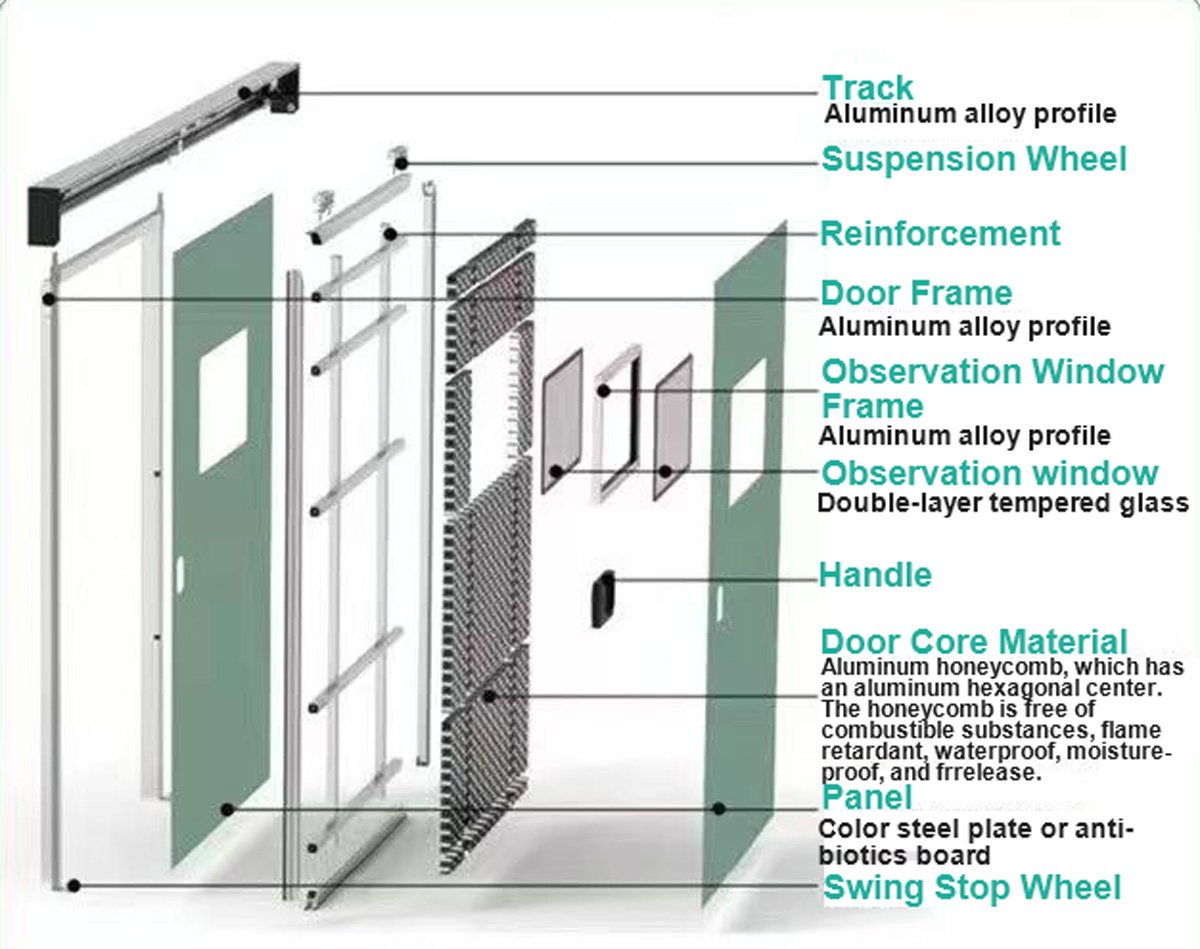

Product Structure and Materials

Frame

The internal frame is welded from 40×50 mm galvanized steel tubes, ensuring robust construction, resistance to rust, and long-term structural stability of the door.

Door Panel Material for Radiation Protection Doors

The door surface is constructed from premium 304 stainless steel, offering exceptional hardness, durability, and impact resistance — ideal for high-demand environments. Designed for superior sealing performance, the door panel features a seamless structure without gaps, enhancing radiation shielding efficiency and improving the overall aesthetic. This high-quality material choice ensures that our lead-lined radiation protection doors maintain long-lasting protection and a clean, professional appearance.

High-Standard Lead Core Plate

Manufactured from No. 1 grade electrolytic lead in compliance with national standards, the lead core offers a smooth surface, uniform thickness, and is free of oxidation, inclusions, bubbles, and cracks.

Steel Keel Frame

The structure is supported by a welded square tube keel frame. We use steel frames manufactured to national standards, featuring high hardness, excellent toughness, and strong resistance to deformation. All frames have passed quality inspection and certification.

Protective Layer

The core protective layer uses radiation-proof lead sheets with a purity of 99.994%. Depending on the parameters of the radiation equipment, different lead thicknesses (lead equivalencies) are applied to meet varying radiation protection requirements.

Door Surface

The door surface is clad in high-grade 304 stainless steel, offering excellent corrosion resistance, mechanical strength, and durability. The smooth, attractive finish ensures the double-leaf lead doors remain aesthetically pleasing and resistant to chemical damage. Custom color options are available to harmonize with different environments, enhancing comfort and visual appeal.

Types and Opening Methods

Types

Double-leaf lead doors are available in two main types: Electric Double-Leaf Lead Doors and Manual Double-Leaf Lead Doors.

Electric Double-Leaf Lead Doors: Powered by an electric system, available in overhead (top-drive) and bottom-drive configurations based on installation needs.

Manual Double-Leaf Lead Doors: Operated manually, suitable for areas with less frequent usage.

Opening Methods

Electric models can be controlled via wall-mounted buttons or remote controls, offering convenient and flexible operation. Users can also adjust the opening and closing speeds based on specific requirements. Manual doors rely on human force for operation.

4. Safety Design Features

Each door is equipped with built-in infrared sensors and motion detectors. If a person or object approaches during door operation, the door will automatically stop and reopen to prevent injuries—providing enhanced protection for patients, children, and medical staff.

Specifications and Weight

Typical radiation-shielded double-leaf lead doors weigh between 200 to 500 kilograms, depending on the lead equivalency and door dimensions.

Designed with reinforced top and bottom pivots, the doors have a bearing capacity exceeding 800 kg, while the gap between the door leaves is kept below 5 mm to prevent sagging or deformation over time.

Application Scenarios

Medical Field

Double-leaf lead doors are widely used in:

Radiology rooms for fluoroscopy, X-ray imaging, CT scanning, dental imaging, and tomography

Radiation therapy rooms such as linear accelerator rooms, gamma knife protection, and afterloading rooms

Nuclear medicine facilities like PET-CT and radionuclide treatment rooms

Other clinical applications such as lithotripsy units, bone densitometry, and X-ray diffraction labs

Other Industries

Beyond healthcare, these radiation protection doors are also used in fields such as geological exploration, food safety testing, material analysis, nuclear power plants, and nuclear weapons manufacturing, primarily to prevent radiation leakage.