Lead Sheet Manufacturers

Raw material cost advantage: Own lead mines or long-term cooperative mines, raw material procurement costs are 15%-20% lower than the market price.

Vertical production quality control: smelting → rolling → quality inspection complete the entire process independently, lead purity is stable ≥99.99%.

Quick customization response: 24-hour order production, thickness (0.5-100mm), size, coating can be flexibly adjusted as needed.

Direct logistics to reduce losses: Own fleet/dedicated line transportation, eliminate intermediate turnover, and ensure that the plate has no scratches or deformation

As the source factory of lead plate manufacturers, we realize the independent production of the entire chain of lead ore smelting → refining and purification → rolling forming → deep processing, ensuring the purity of lead plate ≥99.99% and the thickness tolerance is controlled at ±0.05mm. Relying on 10,000-ton production capacity and 24-hour flexible production line, we support 0.5-100mm over-standard customization, 72-hour ultra-fast delivery, and the cost is 15%-20% lower than the market average price.

Product technical details

1. Material technology

High-purity lead base: electrolytically purified lead ingots (Pb content ≥99.995%), adding 0.3%-0.8% antimony to improve creep resistance

Surface treatment: PVC/stainless steel coating (0.3-1.0mm), anodizing, sandblasting anti-oxidation

Physical properties: density 11.34g/cm³, Vickers hardness 8-12HV, elongation ≥45%

2. Precision specifications

Thickness: 0.5mm (medical thin plate) to 100mm (nuclear thick plate)

Size: standard plate 1×2m/1.2×2.4m, coil width 1m, length 30m (≤3mm)

Lead equivalent: support 0.5-50mmPb customization, error ≤±0.1mm

3. Authoritative certification

National standard: GB/T 1470-2020 (nuclear industry), YY 9706.268-2023 (Medical)

International: ASTM B749, NCRP 147, ISO 14146 Radiation Shielding Verification

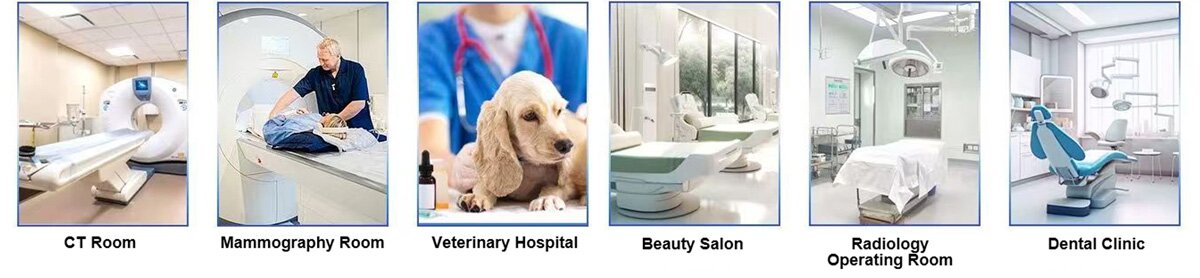

Core Application Scenarios

Medical Field

Radiotherapy Room: 15mm lead plate wrapped linear accelerator, scattered ray leakage <0.05μSv/h

Interventional Surgery Protection: 2mm lead equivalent mobile screen, reducing 90% of the doctor's hand radiation dose

PET-CT wall: lead boron polyethylene composite plate shielding 511keV gamma rays

Nuclear Energy Industry

Reactor Maintenance Wall: 30mm lead-steel composite structure, neutron shielding rate >98%

Nuclear Waste Container: 40mm lead plate lining + external carbon steel, surface dose rate <1.5mSv/h

Fuel Transportation Channel: Lead Coil Fast Laying, γ-ray Instantaneous Attenuation Rate 85%

Industry and scientific research

Industrial flaw detection room: 6mm lead plate wall + automatic lead door, Ir-192 shielding rate 99.9%

Synchronous radiation device: precise splicing of special-shaped lead blocks, absorbing 10-100keV secondary radiation

Radioactive laboratory: modular lead brick wall (50×100×200mm), flexible construction of shielding area

Innovative solutions

Mobile protection unit: 3mm lightweight lead plate composite carbon fiber, 48 hours to build emergency CT cabin

Intelligent splicing system: laser positioning + hydraulic bite technology, to achieve large-size lead plate gap ≤1mm

Recycled lead application: recycling waste lead to regenerate lead plate (purity 99.99%), reducing costs by 30%

With source manufacturing strength + radiation protection science as the core, we provide cost-effective, zero-leakage lead plate solutions for global medical, nuclear energy and high-precision fields.