Lead Sheet X Ray

X-ray lead plates offer superior shielding effectiveness and precise lead equivalent matching. They are strong, durable, corrosion-resistant, and non-deformable. They provide comprehensive protection and significantly attenuate X-rays. Flexible customization is available to meet diverse needs. They are safe, environmentally friendly, and meet international standards. QITE's professional workmanship safeguards radiation safety, providing reliable support for the medical and industrial sectors.

QITE X-ray Lead Sheet: The Core Choice for Professional Protection and Precision Shielding

QITE X-ray Lead Sheet is a high-performance protective material designed specifically for efficient X-ray radiation isolation. It is widely used in critical protective projects in medical diagnostics, industrial testing, and scientific research. Its core value lies in its precision manufacturing and scientific structural design, ensuring superior shielding effectiveness while balancing durability, safety, and flexible adaptability, creating a solid and reliable radiation safety barrier for personnel and the environment.

1. Core Advantages: Professional Protection, Trustworthy

Superior Shielding Effectiveness: Utilizing high-purity electrolytic lead with a purity of ≥99.99% and precisely controllable lead equivalent (customizable from 0.5mmPb to several mmPb), it offers excellent attenuation for diagnostic and industrial-grade X-rays, significantly reducing the risk of radiation leakage.

Excellent Durability and Stability: Featuring exceptional resistance to deformation and corrosion (specially treated surface), it maintains stable shielding performance over long periods of use and is adaptable to complex environments.

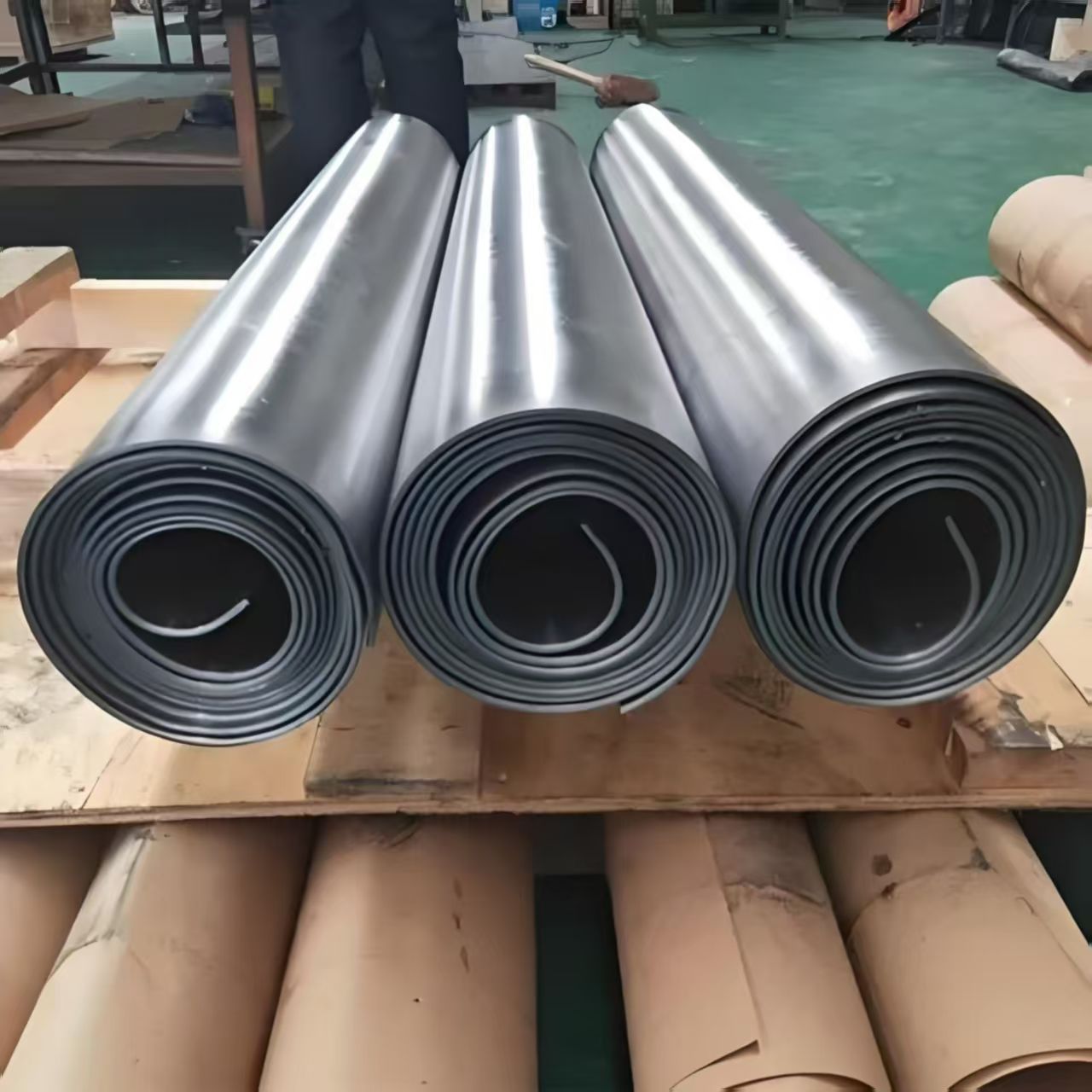

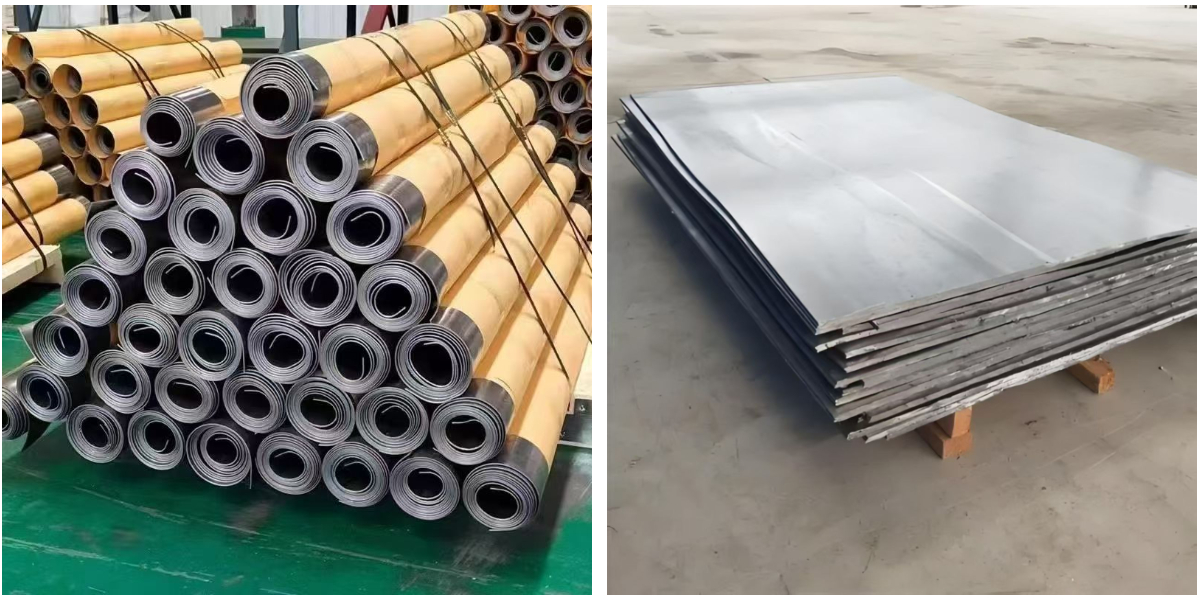

Dense and Uniform Structure: Advanced rolling technology ensures a dense, bubble-free, and gap-free lead layer, eliminating weak points and ensuring more uniform and reliable shielding.

Flexible Customization: Supports non-standard dimensions, custom cuts, and curved surface processing, perfectly adapting to complex installation requirements such as CT room walls, DR room observation windows, protective door infill, and movable screens.

Safety and Environmental Certification: Raw materials comply with RoHS environmental standards, and the production process strictly adheres to ISO and radiation protection industry standards, with authoritative test reports provided.

2. Main Applications: A cornerstone of protection in multiple scenarios

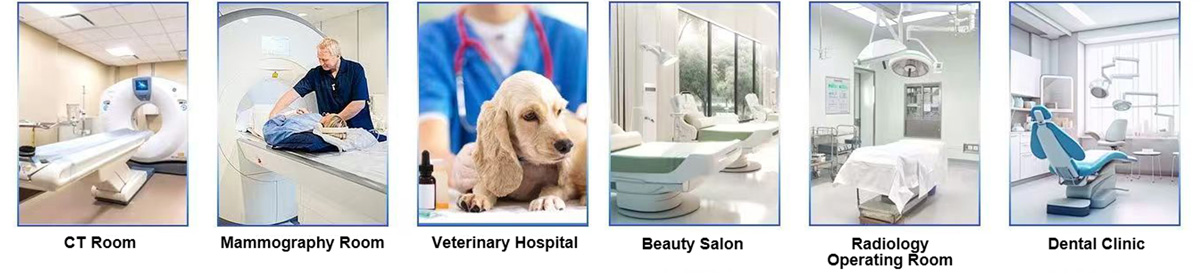

Medical: Builds core shielding layers for walls, floors, ceilings, and protective doors/windows in DR rooms, CT rooms, dental X-ray rooms, mammography rooms, and interventional surgery rooms (DSA).

Industrial: Used in X-ray non-destructive testing rooms (walls and doors), container/vehicle security system shielding, and industrial CT equipment protective cabins.

Supporting Protection: Manufactures lead screens, lead apron storage cabinets, lead glass frames, and linings for radioactive source storage containers.

Research and Other Applications: Nuclear technology laboratories, veterinary hospital X-ray rooms, airport security back-end protection, etc.

3. Precision Structure: Ingenious Design, Multiple Safeguards

Qite X-ray Lead Sheet features a composite reinforced structure design, balancing protection and workability:

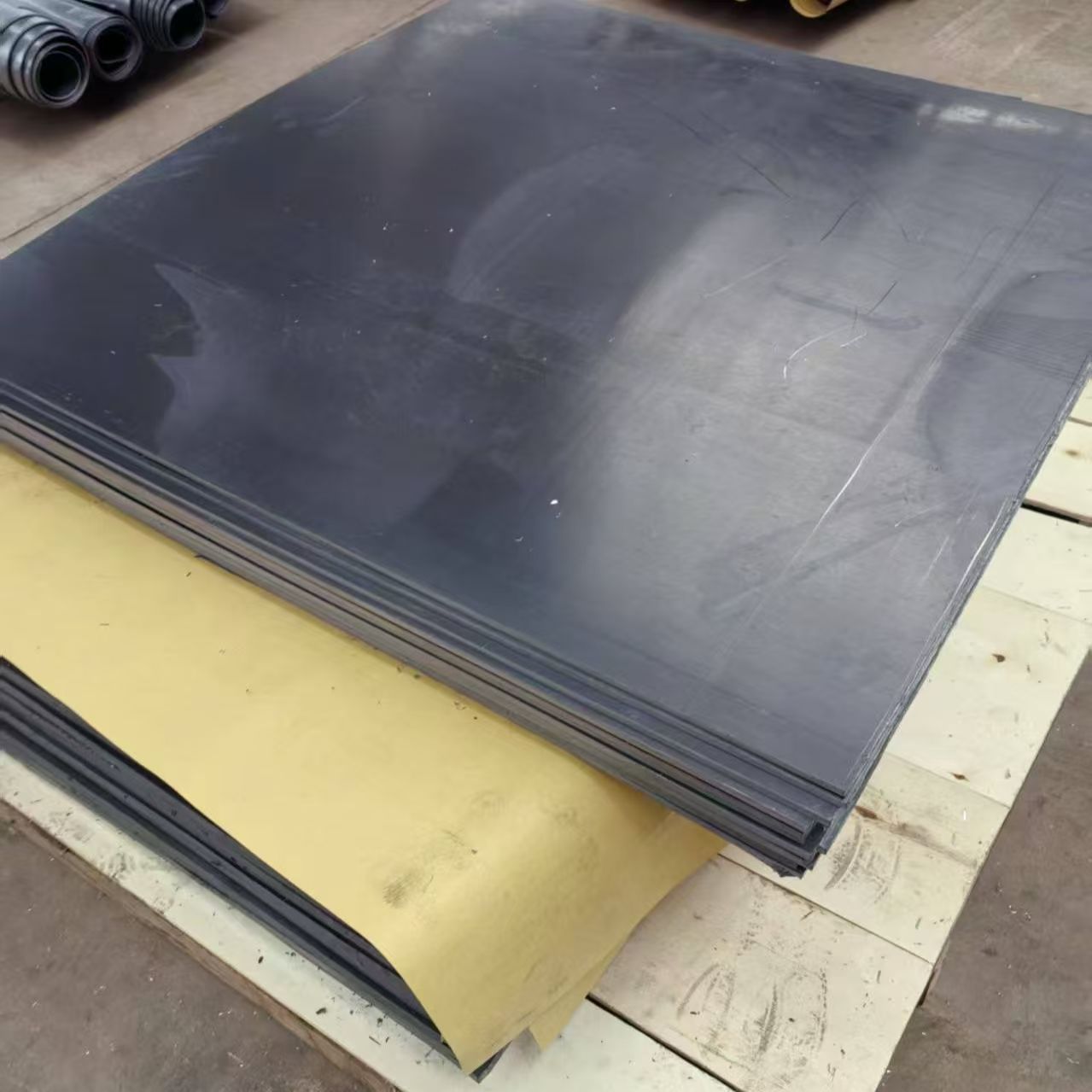

High-Strength Protective Surface (Optional): The outer layer can be laminated with galvanized steel, stainless steel, or PVC film to enhance surface hardness, scratch resistance, and aesthetics, making it easy to clean and disinfect (especially suitable for medical environments).

Core Pure Lead Layer: High-purity lead sheet serves as the core protective medium. The thickness is scientifically determined based on the protection requirements (lead equivalent) to ensure that radiation attenuation meets the design standard.

Stable Substrate Support (Composite Sheet): Composite lead sheet is laminated with a solid substrate (such as MDF or steel) to significantly improve overall impact resistance and flatness, facilitating installation and fixing, and preventing deformation associated with pure lead sheet.

Precision Edge Treatment: Cut edges are smooth and flat, with no exposed lead layer (composite sheet), preventing oxidation contamination and ensuring the safety of installers and a clean environment.

Easy Installation: Can be nailed, drilled, and bent (with limitations), allowing for a tight fit with building structures, streamlining the construction process and reducing the risk of leaks at joints.

Qite X-ray lead sheet, with its high-purity core, precision composite structure, strict quality control standards, and extensive customization capabilities, has become an indispensable foundational material in radiation protection projects. Whether for new construction or renovation, Qite provides protection solutions that meet safety regulations and offer stable, long-lasting performance, strengthening X-ray safety for users in various fields. Choosing Qite means choosing a dual guarantee of protection effectiveness and long-term reliability.

Why choose our lead plates?

1. As a manufacturer in the X-ray protection field, we are deeply engaged in lead plate research and development and production, focusing on providing products that meet our customers' personalized needs.

2. We have a robust quality system and hold multiple authoritative certifications. Every lead plate undergoes rigorous testing to meet the highest global protection standards.

3. Our lead plates are designed for wide applicability, meeting protection needs in various scenarios. At the same time, committed to promoting industry development, we integrate modern technology to continuously upgrade the quality and performance of our lead plates.

4. Our in-house factory offers significant price advantages. Our years of experience in export customization allow us to precisely meet the specific needs of the market.

5. We are committed to providing high-quality service throughout the entire process, ensuring a worry-free experience in lead plate selection and use. Our in-house professional team provides dual guarantees for our products and services.

FAQs

Q: Do you offer OEM services?

A: We support custom production, manufactured to your exact specifications. Providing reference samples ensures a precise match.

Q: Can you accept small orders?

A: In-stock products can be shipped immediately; out-of-stock orders will be consolidated, requiring a reasonable turnaround time.

Q: Is there a sample fee? How are shipping costs handled?

A: Samples are available free of charge, and shipping costs will be deducted from the order amount after placing an order.

Q: How is the radiation protection performance of the product verified?

A: Every lead plate undergoes professional testing before leaving the factory, and a third-party lead equivalent report is available.

Q: How is the order fulfillment process followed up?

A: After production begins, we regularly send photos of the actual product and videos of key processes for full transparency.

Q: Do you provide installation guidance or after-sales service?

A: We provide free remote installation guidance and operator training, as well as lifetime technical support.