Medical Lead Screen

Absolute protection:

≥2.0mmPb lead equivalent (150kVp working condition), scattered radiation attenuation 99.5%, operating position dose <2.5μSv/h, exceeding the national standard safety margin.

Flexible and durable:

Medical silent universal wheels + gravity self-locking, 0.5 second emergency stop during surgery; 304 stainless steel integrated shell withstands daily disinfection, 10 years of lead layer without attenuation.

Smart adaptation:

Supports arc/folding/top extension customization, compatible with orthopedic intervention scenarios; lead glass transmittance >82% without blind spots.

Compliance and rigid demand:

Complies with YY/T 1847-2022 medical standards, FDA 510(k)+CMA dual certification, closed loop of hospital infection prevention and control.

Medical shielding screen is a professionally designed mobile or fixed protective device. Its core function is to effectively attenuate and absorb X-ray radiation, providing a vital safety barrier for medical staff, operators and the surrounding environment. It is mainly used to isolate the ionizing radiation generated by X-ray sources (such as X-ray machines, CT scanners, DSA equipment, industrial flaw detection equipment, etc.) and reduce the radiation dose to within the safety standard.

Key features and materials

High-efficiency shielding materials:

The core shielding layer uses high-purity lead (Pb) or lead-containing composite materials (such as lead rubber, lead plastic board). Due to its high atomic number and density, lead has excellent absorption capacity for X-rays.

Lead equivalent (Pb eq) is the core indicator: it refers to how many millimeters of pure lead plate the shielding material is equivalent to when attenuating X-rays of a specific energy. Common lead equivalents range from 0.5mmPb to 3.0mmPb or higher. Users need to choose the appropriate lead equivalent according to the equipment type (tube voltage kVp), working distance, and expected shielding effect (such as compliance with national standards GBZ 130/GB 18871).

Structural design:

Mobile screens: Usually equipped with a sturdy metal frame (such as stainless steel, aluminum alloy), universal casters (with brakes), which are convenient for flexible movement and positioning in the examination room. Common heights are 1.8 meters to 2.2 meters, and widths are 1 meter to 1.5 meters (single or double leaf combination).

Fixed screens/partitions: Embedded in the wall or as an independent partition to provide permanent protection.

Observation window: Integrated lead glass window, the lead equivalent is consistent with the main shielding (common 15-20mm thick lead glass, lead equivalent ≥0.5mmPb), ensuring that the operator's vision is not obstructed when safely observing the patient and equipment status.

Surface Covering: The outer layer of the lead plate is covered with wear-resistant and easy-to-clean protective materials (such as stainless steel plates, fireproof boards, antibacterial coated cloth), which is beautiful, durable and hygienic.

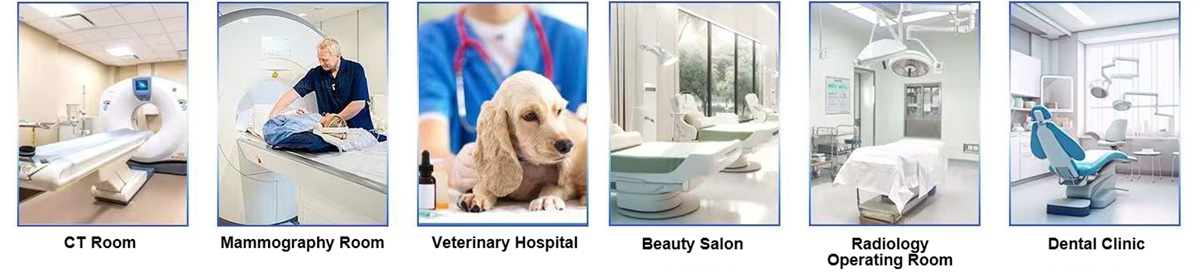

Main Application Scenarios

Medical Radiology: X-ray photography room, DR/CR room, CT scanning room control area, interventional catheter room (DSA) operation position, dental X-ray room.

Veterinary clinic: Animal X-ray inspection protection.

Industrial Nondestructive Testing (NDT): Operator protection area at industrial X-ray and gamma ray flaw detection sites.

Security Inspection Field: Operator protection of baggage/cargo X-ray security inspection equipment.

Nuclear Technology Application: Laboratories or workplaces that require local shielding of X-rays.

Advantages and Values

Personnel Safety: Minimize the radiation dose received by operators and nearby personnel, prevent the risk of deterministic effects and stochastic effects, and ensure occupational health.

Compliance with regulations: Meet the requirements of national and international radiation protection regulations (such as China GB standards, NCRP, ICRP recommendations) for workplace partition shielding and personnel dose limits.

Easy to operate: The mobile design is flexible to adapt to different inspection needs; the observation window ensures visibility of operation.

Reliable and durable: High-quality materials and structures ensure long-term stable shielding performance and physical strength.

Necessary protection: It is an indispensable basic safety equipment for any workplace that generates ionizing radiation (X-rays).

Safety certification

Formal products should pass relevant national or international safety standard certification (such as medical device registration and filing, ISO 9001 quality management system, radiation protection performance test report) to ensure their protection effectiveness and reliability.

Summary: X-ray radiation shielding screen is a protective barrier composed of high lead equivalent materials (lead plate/composite materials) as the core, combined with a solid frame and lead glass observation window. Its core value lies in providing reliable protection for operators in radiation risk areas and ensuring that the radiation dose meets safety standards. It is an indispensable safety protection solution in medical diagnosis, industrial testing and other fields. When choosing, you need to focus on lead equivalent, size, mobility and compliance certification.