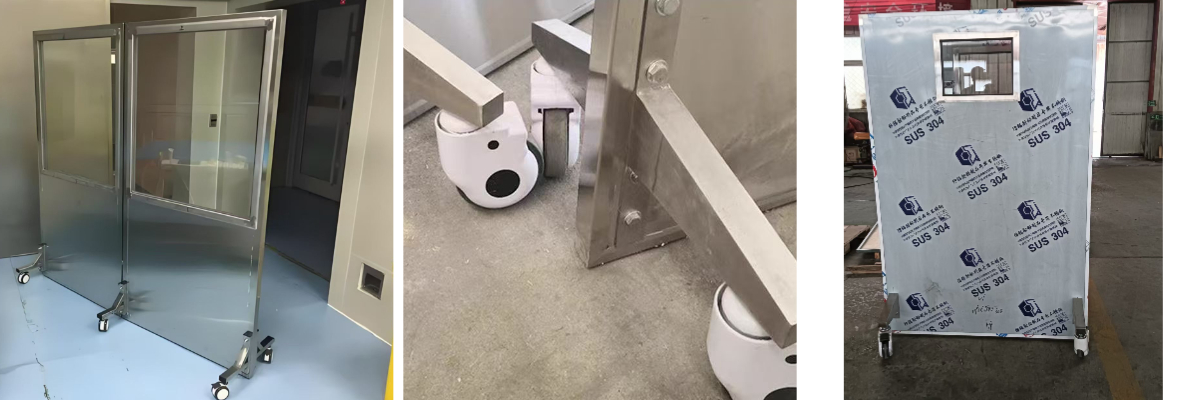

Mobile Lead Screen

Efficient protection: High-density lead material effectively blocks ionizing radiation such as X-rays and gamma rays to protect personnel safety.

Flexible and portable: Lightweight design, movable and foldable, suitable for multiple scenarios such as hospitals and laboratories.

Durable and stable: Anti-corrosion and anti-oxidation, long-term use performance does not decay.

Strong customization: The size and thickness can be adjusted according to needs to match different protection levels.

Environmentally friendly and economical: Lead materials are recyclable, taking into account both environmental friendliness and cost-effectiveness.

It is an ideal choice for radiation protection in medical, nuclear industry and other fields.

Lead screen is a kind of professional radiation protection equipment, which is widely used in places with ionizing radiation risks such as medical treatment, nuclear industry, scientific research laboratories, etc. Its core function is to absorb and block harmful radiation such as X-rays and gamma rays through high-density lead materials to ensure the safety of personnel and the environment. The following is a detailed analysis of lead screen:

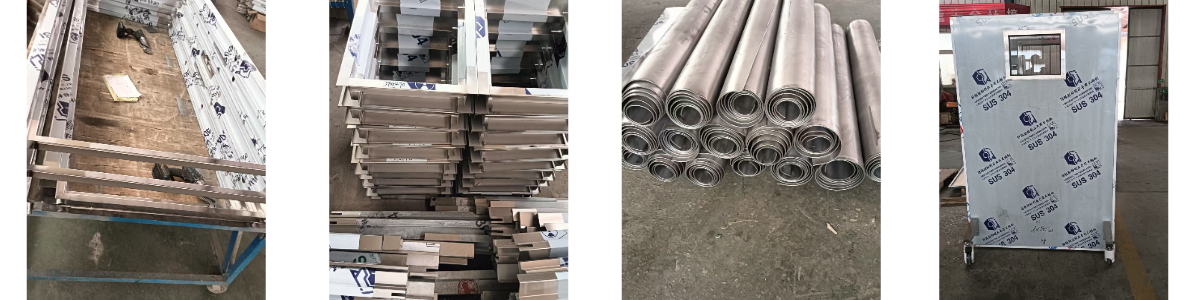

1. Structure and materials

Lead screens are usually composed of multi-layer structures:

Lead core layer: high-density lead plate (thickness 1-10mm) with a purity of ≥99.99% is used. The lead equivalent (protection ability) can be customized according to needs, such as 0.5mmpb to 5mmpb, to meet different radiation intensity scenarios.

Support frame: The outer layer is mostly aluminum alloy, stainless steel or engineering plastics, which enhances the structural stability and reduces the overall weight.

Surface treatment: Some products are covered with fireproof and anti-fouling coatings, or PVC coatings are used to facilitate cleaning and disinfection, and adapt to the needs of medical environments.

2. Application scenarios

Medical field: used in radiology departments, CT rooms, interventional operating rooms, etc. to protect medical staff from long-term radiation exposure.

Nuclear industry: radiation isolation areas in nuclear power plants and nuclear waste treatment plants to ensure the safety of operators.

Scientific research experiments: temporary shielding of high-energy physics laboratories and radioactive material research sites.

Industrial inspection: X-ray flaw detection and perimeter protection of security inspection equipment.

3. Technical parameters and types

Lead equivalent: a key indicator for measuring protection capabilities, which needs to be selected according to the intensity of the radiation source, such as 1-2mmpb commonly used in interventional operating rooms.

Size specifications: height 1.8-2.2 meters, width 0.6-1.5 meters, can be customized with oversized size or splicing design.

Weight: The lightweight design keeps the weight of a single screen at 20-80kg, and the bottom is often equipped with universal wheels for easy movement.

Type: divided into fixed, mobile, folding (such as screens that can be unfolded 180°) and transparent lead glass composite (taking into account observation needs).

4. Installation and maintenance

Installation: modular design, supports quick splicing, and some products require pre-buried tracks or fixed brackets.

Maintenance: Check the integrity of the lead layer regularly to avoid gaps caused by mechanical collision; the surface can be wiped with a neutral detergent, and corrosive liquids are prohibited.

5. Safety certification and standards

Comply with the International Commission on Radiological Protection (ICRP) and national standards (such as GBZ 130-2020 Medical Radiation Protection Requirements), and some products have passed ISO 9001 quality management system certification to ensure reliable protection effectiveness.

6. Customized service

Supports adjustment of lead layer thickness, screen size, and appearance color according to scene requirements, and can add additional functions such as observation windows and access control interlocking systems to achieve precise protection.

7. Environmental protection and economy

Lead materials can be 100% recycled and reused to reduce long-term use costs; high-durability design reduces replacement frequency, and the overall cost-effectiveness is significant.

Summary: Lead screens have become indispensable equipment in the field of radiation protection due to their high-efficiency protection, flexible adaptation, safety and durability. Their technological iterations (such as lightweight and intelligent) have further expanded the application scenarios and provided reliable protection for multiple industries.