Heavy Duty Single Lead Door

Efficient protection: High-density lead core (lead equivalent 3-15mm) combined with steel frame effectively shields X-rays, gamma rays and neutron radiation, meeting the stringent protection needs of the medical and nuclear industries.

Stable and durable: Heavy-duty hinges bear more than 1.5 tons, the door body is resistant to deformation, and will not deform after long-term use, with a service life of more than 20 years.

Sealed and leak-proof: Multi-layer sealing strips + sunken threshold design block radiation leakage, and the airtightness reaches the industry's high standards.

Safe and intelligent: Standard anti-pinch device and electronic interlocking system, linked with radiation equipment to ensure safe operation.

Silent and low-consumption: Bearing pulley and buffer design, smooth and silent opening and closing, and extremely low maintenance cost.

Widely applicable: Surface anti-corrosion treatment, suitable for hospitals, laboratories, nuclear facilities and other scenes, in line with international protection standards such as GBZ130-2020.

Heavy-duty swing lead doors are special protective doors designed for high-radiation environments. They are widely used in hospital radiology departments, nuclear power plants, industrial flaw detection rooms, laboratories and other scenarios. Their core function is to block the leakage of ionizing radiation (such as X-rays, gamma rays, neutron flow) to ensure the safety of personnel and the environment. The following are detailed technical parameters and design features:

1. Structure and materials

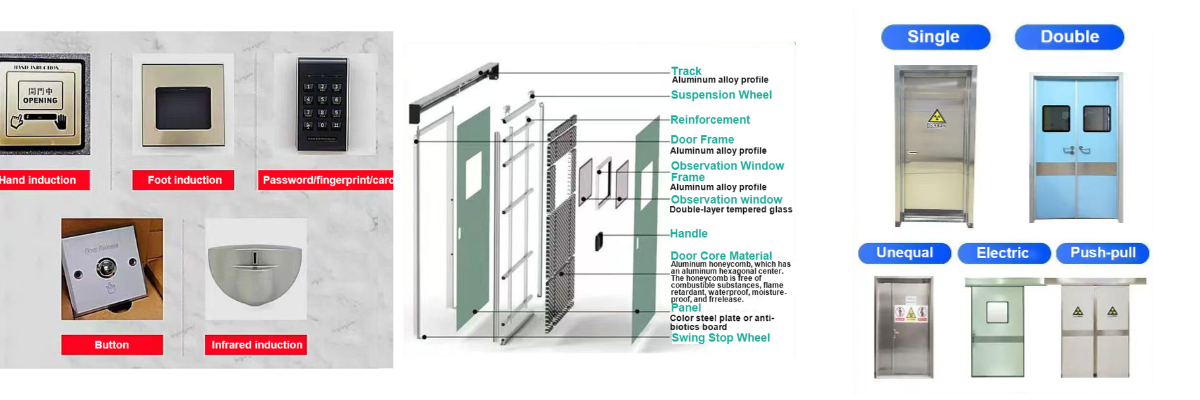

Door structure: It adopts a composite multi-layer structure, embedded with high-purity lead plates (purity ≥99.99%), and the lead equivalent covers 3mm to 15mm, which can be customized according to protection needs; the outer layer is a high-quality cold-rolled steel plate (thickness 1.5-3mm), and the surface is phosphated and electrostatically sprayed for corrosion resistance and oxidation resistance.

Frame reinforcement: The door frame is welded with channel steel or square steel, and reinforcement ribs are added inside the door leaf. The overall compressive strength is ≥5000N/m², which can resist external impact deformation.

Protection extension: Some models support lead glass windows (lead equivalent matches the door body) to facilitate observation of the internal situation.

2. Sealing and airtightness

Multi-layer sealing design: EPDM rubber sealing strips (radiation-resistant and aging-resistant) are installed at the door gaps, and multiple sealing layers are installed at the top, bottom and sides. Combined with the sunken stainless steel threshold (adjustable in height), the airtightness is ensured to reach a leakage rate of <1.5% under a pressure difference of 10Pa.

Automatic clamping device: When the door is closed, the sealing strip is automatically clamped by a mechanical lock or pneumatic system to eliminate the risk of radiation leakage from the gap.

3. Load-bearing and opening system

Heavy-duty hinges: High-strength alloy steel bearing hinges are used, and the single hinge has a load-bearing capacity of ≥1.5 tons, supports more than 100,000 openings and closings without wear, and the maximum size of the door leaf can reach 2500mm×3000mm.

Smooth operation: The bottom is equipped with nylon guide wheels or heavy-duty ground wheels, and is equipped with a hydraulic buffer door closer. The opening and closing process is low-noise (≤45dB), and the opening and closing force is ≤100N.

Safety protection: standard infrared anti-pinch sensor device and emergency stop button, the door and radiation equipment are linked through an electronic interlocking system (interlocking controller), and the equipment cannot be started when it is not fully closed.

4. Intelligent control and compatibility

Control mode: supports manual, electric (220V/380V motor drive) and remote control, and some models integrate access control systems such as card swiping and fingerprint recognition.

Compatible design: can be connected to DICOM system (medical scene) or industrial PLC to achieve automated coordination with radiation equipment and ventilation system.

5. Standards and certifications

Complies with GBZ130-2020 "Radiation Protection Requirements for Medical X-ray Diagnosis", GB/T18871-2002 "Basic Standards for Ionizing Radiation Protection and Radiation Source Safety" and ISO2919 International Nuclear Facility Protection Specifications, and is suitable for IAEA (International Atomic Energy Agency) recommended scenarios.

6. Installation and maintenance

The installation requires pre-buried steel door frames, the ground bearing capacity is ≥200kg/m², and the joints between the door and the wall are filled with radiation-proof mortar;

Daily maintenance only requires regular inspection of the sealing strips and hinge lubrication, no special maintenance is required, and the service life is ≥20 years.

Summary: Heavy-duty flat-opening lead doors achieve zero radiation leakage, convenient operation and long-term stability through high-density lead cores, reinforced structures, intelligent security and multiple sealing technologies. They are core protective equipment in the fields of nuclear medicine and industrial flaw detection.