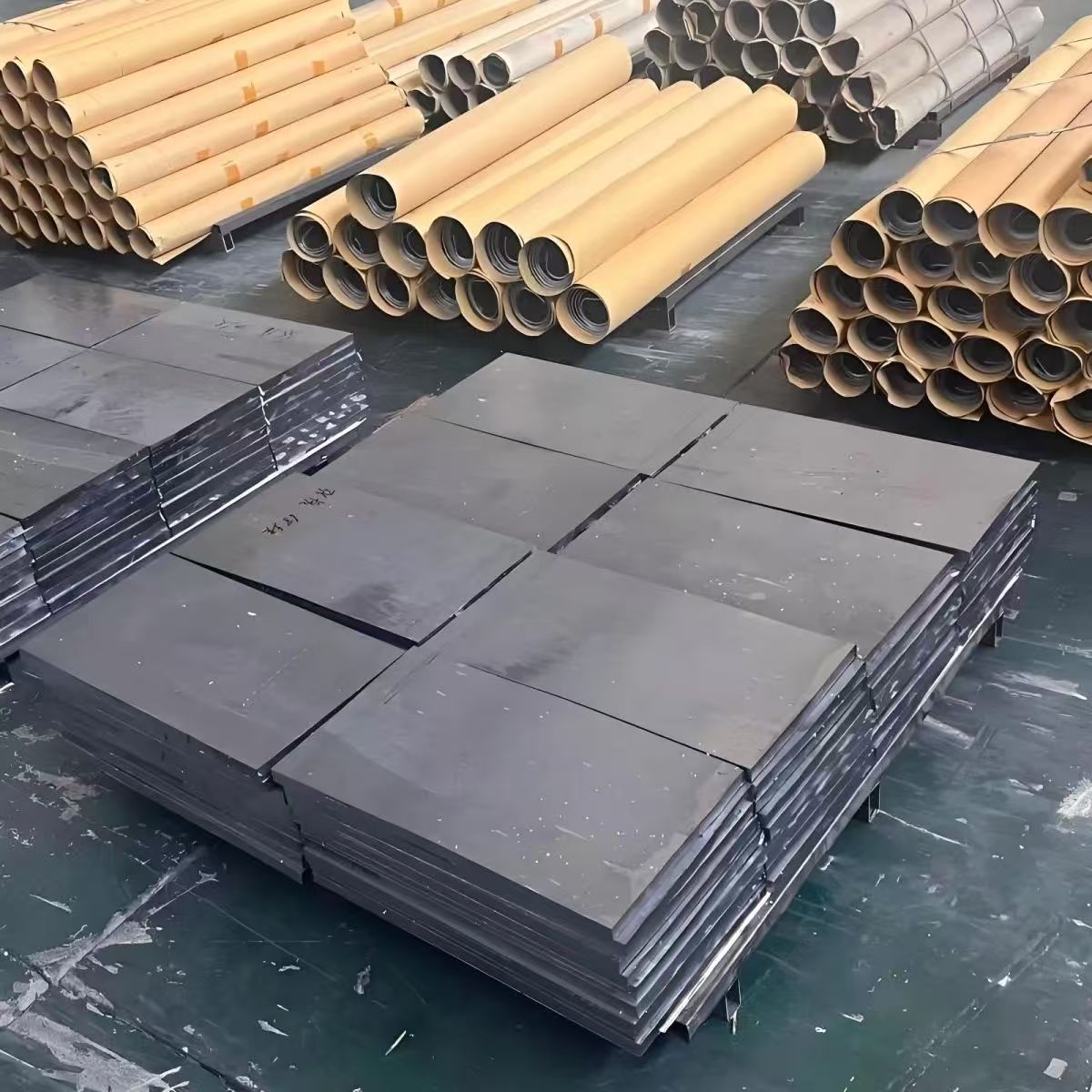

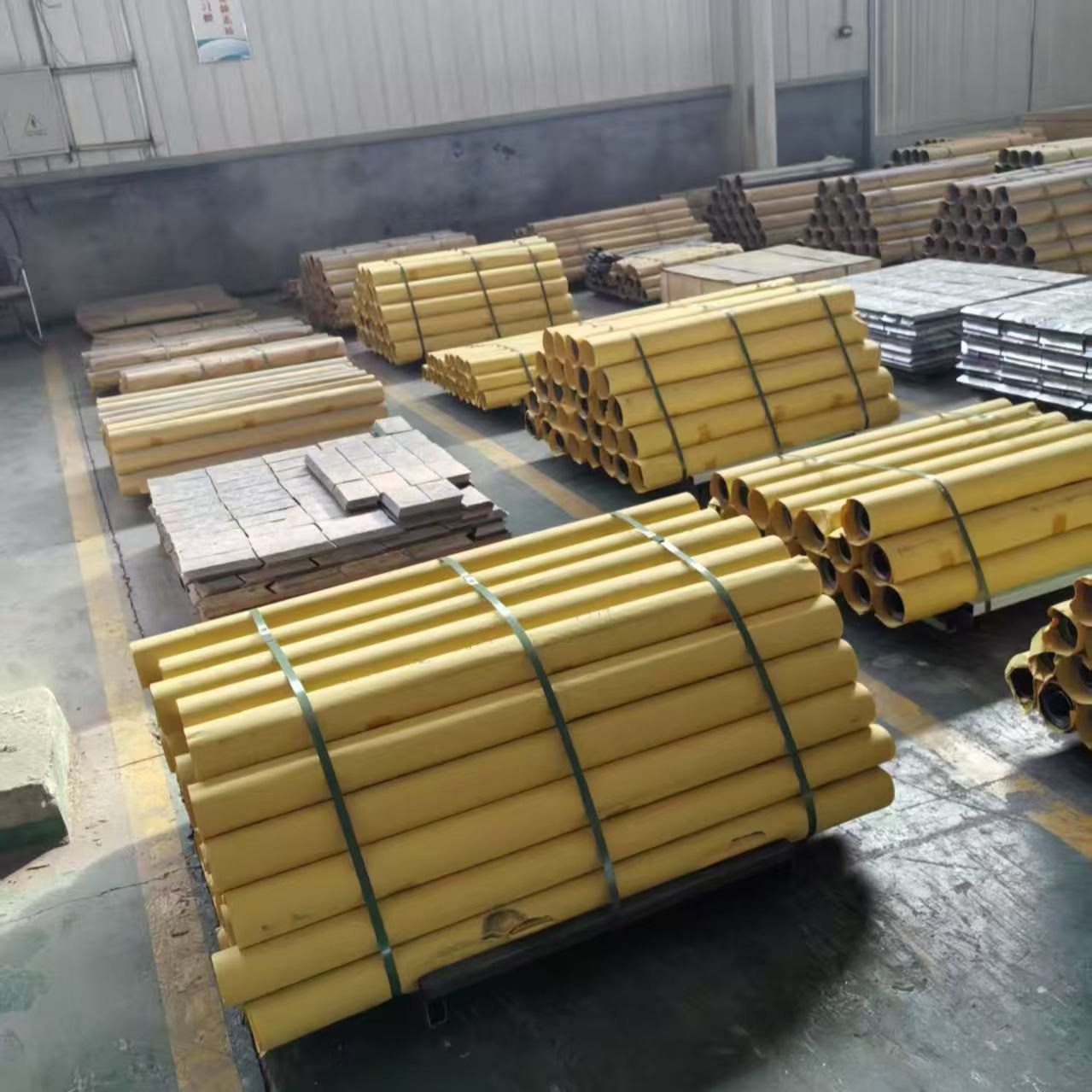

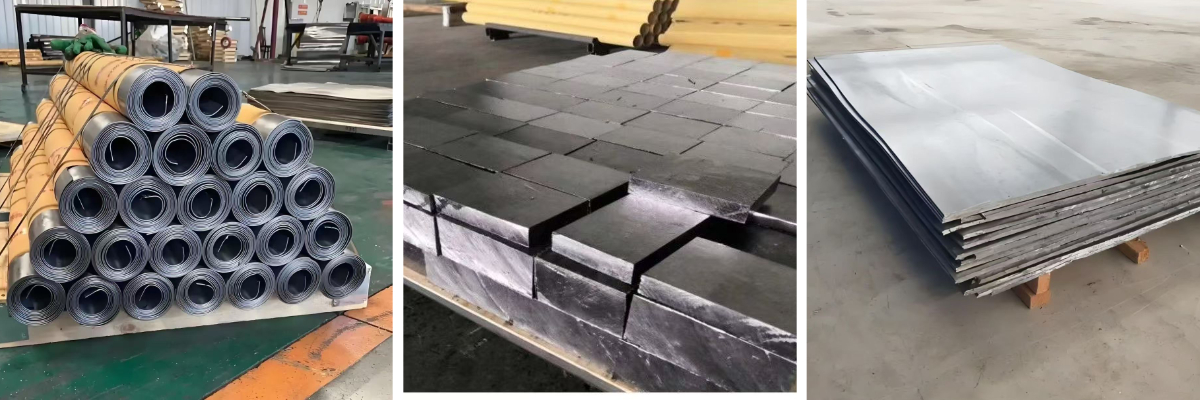

Lead Sheet Protection

xcellent protection: High density (11.34 g/cm³) effectively shields X-rays, gamma rays and nuclear radiation, and is widely used in medical and nuclear industry protection.

Corrosion resistance and stability: Acid and alkali resistance, atmospheric corrosion resistance, long-term use in chemical industry, battery lining and other environments.

High plasticity: Good ductility, easy to cut, bend and shape, suitable for complex engineering structure requirements.

Vibration reduction and counterweight: High density and strong damping, suitable for precision equipment vibration reduction base and ship counterweight balance.

Radiation-proof lead sheet is made of 99.99% high-purity lead with trace antimony/calcium for reinforcement. With an ultra-high density of 11.34g/cm³, it absorbs radiation energy efficiently through the photoelectric effect. 1mm thickness can achieve the protection equivalent of 1 meter of concrete, which is an irreplaceable core material for radiation protection in the medical and nuclear industries.

Absolute protection efficiency

The shielding rate of medical X-rays (80-150kV) is greater than 99.5%, and the attenuation intensity of gamma rays (cobalt-60) is 30% for every 1mm thickness increase, and the lead equivalent error is ≤±0.1mm.

Strong environmental adaptability

Acid and alkali corrosion resistance (pH 3-11 environment), PVC/stainless steel layer on the surface to resist oxidation, life span of more than 20 years. No performance degradation under extreme temperature and humidity.

Flexible and reliable engineering

Thickness 0.5-100mm can be customized freely, and ultra-thin coils (≤3mm) can be installed on curved surfaces; welding/steel reinforcement is supported, and the joints ≤2mm ensure zero radiation leakage.

Full-cycle safety

Complies with GB/T 1470-2020 and YY 9706.268 standards, the recycling rate of waste lead plates is >95%, and the cutting operation is equipped with a negative pressure dust removal system to block the spread of lead dust.

Core application scenarios

Medical field

Radiotherapy room: 10-15mm lead plates wrap the linear accelerator, and the scattered radiation dose is reduced to <0.1μSv/h (international safety limit).

Interventional catheter room: 2mm lead equivalent layer is implanted in the wall to block continuous scattering during surgery and protect the health of the medical team.

PET-CT shielding: dedicated lead door/observation window, blocking 511keV gamma rays, and simultaneously ensuring the safety and visibility of diagnosis and treatment.

Nuclear energy industry

Reactor maintenance layer: 30mm lead-polyethylene composite wall, shielding neutron/gamma mixed radiation, supporting short-term operations of personnel in high-risk areas.

Nuclear waste storage tank: lead plate lining + external steel shell structure, suppressing the surface dose rate of cesium-137 to <2mSv/h.

Nuclear power plant control room: lead glass observation window composite lead plate wall, achieving dual protection of radiation isolation and real-time monitoring.

Industry and scientific research

Industrial flaw detection room: 6mm lead plate covers the wall/door to isolate the gamma ray leakage of Ir-192 flaw detection source.

Synchrotron radiation laboratory: lead plate splicing beam line channel to absorb high-energy electron-derived bremsstrahlung.

Radioactive laboratory: temporary shielding wall with lead bricks to flexibly block the scattered rays of experimental equipment.

Innovative application

Mobile CT cabin: 3mm lightweight lead plate composite carbon fiber body to achieve rapid protection deployment of field emergency detection.

Radiation-proof elevator shaft: lead plate interlayer is integrated into the building structure to shield the residual radiation in the shaft of the hospital's dedicated elevator.

Radiation-proof lead sheet, with its protection capability to the physical limit of materials, continues to build a safety foundation for human medical health, clean energy and technological exploration.