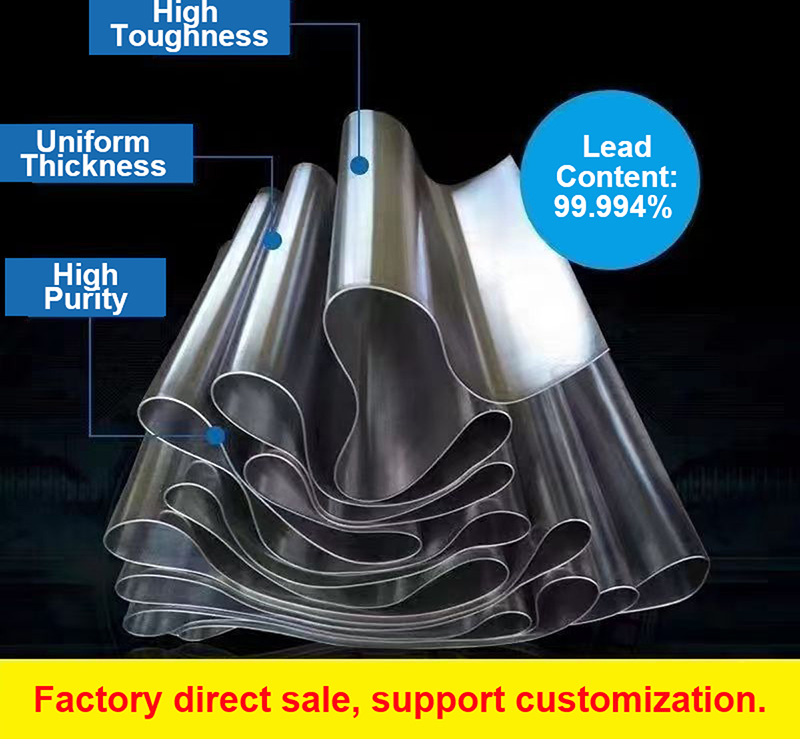

Lead Sheet Metal

Lead sheet provides excellent radiation shielding capability with high density (11.34g/cm³), and 10mm thickness can block more than 99% of X/γ rays. It has excellent ductility (ductility ≥45%), supports cold bending and bonding of complex structures, and is easy to construct. It is resistant to strong acids and alkalis (pH 2-12), has a corrosion resistance life of more than 20 years, and is suitable for chemical corrosion protection scenarios. It is 100% recyclable, meets RoHS environmental protection standards, and has no pollution risk. It has both sound insulation and noise reduction functions (30dB+), and has outstanding comprehensive cost performance, making it a core material for medical and nuclear industry protection.

Technical specifications of lead plate products

Material and structure

Material: ≥99.99% high-purity lead (GB/T 1470 standard), density 11.34g/cm³, impurities ≤0.05%

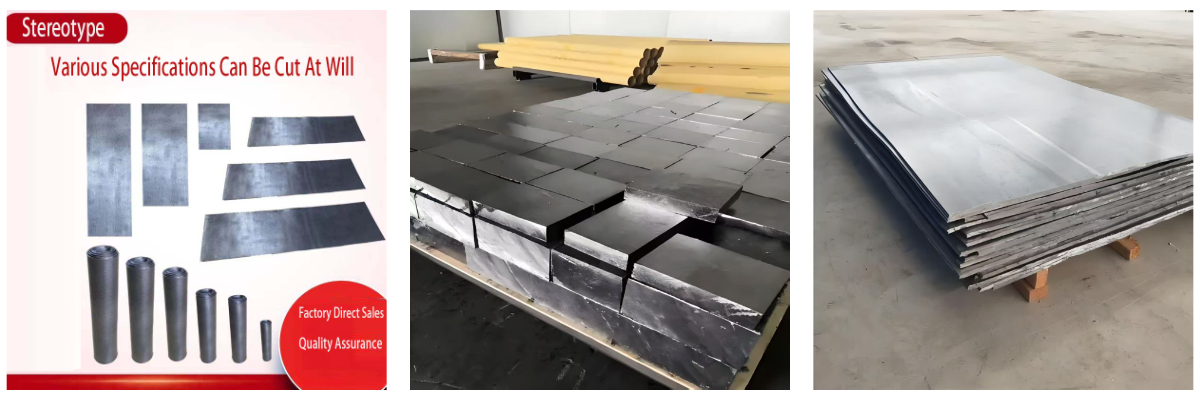

Form: coil (width 100-1500mm, single coil ≤20m) or customized sheet (maximum single plate size 6m×1.5m)

Thickness: 0.1-30mm (±0.05mm tolerance), conventional specifications 0.5/1/2/3/5/10mm

Surface: smooth rolling (default), PVC/EPDM coating (wear-resistant), 304 stainless steel composite (impact-resistant)

Application Scenario | ||

Field | Typical solutions | Technical points |

Medical protection | CT room shielding/lead door/operating room | 2-3mm+0.5mmPb tape seam sealing |

Nuclear power industry | Spent fuel container shielding | 10-30mm lead steel composite structure |

Industrial Anticorrosion | Plating tank lining/anti-corrosion layer | 1-3mm PVC coating to prevent mechanical damage |

Core performance parameters

Lead equivalent 0.5-30mmPb (1mm lead plate ≈ 1mmPb equivalent)

150kV X-ray shielding rate ≥99.9% (10mm thick), γ-ray linear attenuation coefficient 1.29cm⁻¹ (¹³⁷Cs source)

Extreme environment tolerance

Strong acid and alkali resistance (pH 0.5-14), 98% sulfuric acid corrosion volume <0.03mm

Working temperature: -50℃~80℃ (laminated version withstands -196℃ liquid nitrogen to 150℃ steam)

Machinability

Elongation ≥45%, tensile strength 12-18MPa, supports cold bending/stamping/welding (lead welding rod melting point 327℃)

Can fit pipes and special-shaped structures with a curvature radius ≥5D

Safety and environmental protection

100% recyclable, RoHS, REACH and ISO 14001 certified

No heavy metal precipitation (ASTM E1645 Immersion Test)

Technical services and certification

Quality control standards: ASTM B29, EN 12588, ISO 4037 (radiation test)

Test report: Provide SGS material analysis, lead equivalent certificate and salt spray test report (ISO 9227)

Value-added services: Support laser cutting, hemming and corner wrapping, lead-stainless steel composite rolling, and provide radiation protection engineering design solutions

Lead plates have become irreplaceable protective materials in high-end fields such as nuclear energy, medical care, and military industry with ultra-high density shielding effectiveness, extreme environmental stability, and 30-year service life. The comprehensive performance far exceeds that of polymer-based composite materials.