Lead Sheet Roll

High-strength protection: High lead density provides highly effective shielding against X-rays and gamma rays, offering superior and reliable protection.

Flexibility and ease of installation: The soft material is easy to cut, bend, and fit, adapting to various complex installation scenarios.

Stability and durability: Corrosion-resistant and oxidation-resistant, with stable performance and a long service life.

High purity and high efficiency: Lead purity of 99.99% or higher ensures superior protective performance per unit thickness.

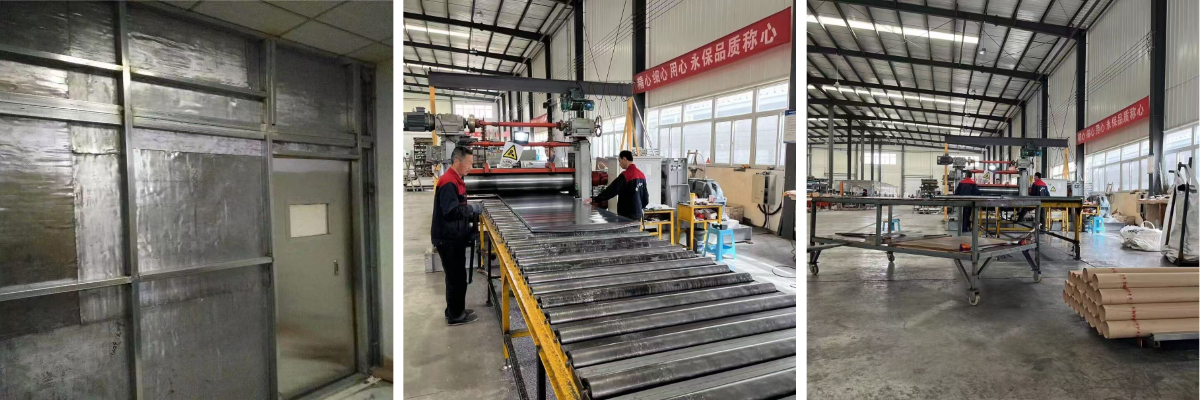

Lead sheet coil is a flexible radiation protection material made of high-purity lead as the main raw material through rolling, coating and other processes. It has both high-efficiency shielding performance and convenient construction, and is widely used in radiation isolation of complex structures in the medical, nuclear industry and construction fields.

Core performance and technical parameters

High-purity radiation protection

Lead content ≥ 99.99%: density 11.34g/cm³, lead equivalent 0.5-3mm adjustable, X-ray and gamma-ray shielding efficiency ≥ 95% energy coverage range 10keV-3MeV, meeting the needs of CT rooms, radiotherapy rooms, nuclear waste storage and other scenarios.

Uniformity detection: Through the X-ray fluorescence thickness gauge detection, the thickness error is ≤ ± 0.05mm, ensuring that there is no dead angle in the protection performance.

Flexible and easy to process

Strong ductility: tensile strength ≥10MPa, elongation ≥40%, can be bent to an arc with a radius of ≥50mm, fits special-shaped structures such as pipes and wall corners, supports secondary processing such as shearing, punching, welding (argon arc welding/lead welding).

Roll design: standard roll width 1m/1.2m, length 10-20m, roll weight 1-3 tons, convenient transportation and storage, construction loss rate <5%.

Corrosion-resistant and durable material

Multi-layer protection process: the surface is covered with 0.2-0.5mm PVC coating or epoxy resin, the inner layer of lead foil is treated with antioxidant treatment, acid and alkali resistance, moisture and mildew resistance, working temperature -20℃ to 60℃, service life ≥20 years.

Environmental protection and safety: fully enclosed coating process, lead powder leakage rate <0.05μg/m³, passed ROHS and SGS certification, non-toxic and harmless, in line with occupational health standards.

Economical and efficient construction plan

Lightweight design: optional thickness of 1-10mm, unit area weight is 10%-15% lower than traditional lead plate, reducing wall load.

Quick installation: Adopt bonding (lead glue) + mechanical fixation (keel/pressing) method, superimpose lead tape (lead equivalent ≥ 0.5mm) at the joint, and improve construction efficiency by 30%.

Application scenarios

Medical field: DR/CT room wall protection, interventional operating room lead curtain, nuclear medicine radiopharmaceutical storage cabinet lining.

Industrial field: nuclear power plant pipeline coating, industrial flaw detection room protection layer, laboratory radiation device shielding.

Architectural field: radiation-proof basement, data room electromagnetic shielding layer, substation wall protection.

Customized service and certification

Flexible adaptation: support non-standard thickness and width customization, provide cutting and processing, welding guidance and protection scheme design services.

Authoritative certification: Passed ISO 9001 quality management system and ISO 14001 environmental management system certification, in line with NCRP 151 international protection recommendations, with a 10-year warranty.

Lead sheet rolls are an ideal choice for complex radiation scenarios with high protection, construction flexibility and long-term durability, helping to achieve safe, economical and environmentally friendly shielding projects.