Radiation Proof Glass

High light transmittance radiation protection material with a light transmittance of ≥85%, lead equivalent coverage of 0.5-8.0mmPb (6mm thick equivalent to 2.5mm lead plate), no blind spot. Density is only 4.2g/cm³ (80% lighter than concrete), which greatly reduces the load. Medical optical grade accuracy (refractive index 1.52±0.01, distortion <0.1%), true image. Super durable (Mohs hardness 5.0, resistant to 10⁶Gy radiation, life span >20 years). Passed ISO 12757-1 certification, the lead layer is stable, professional and reliable.

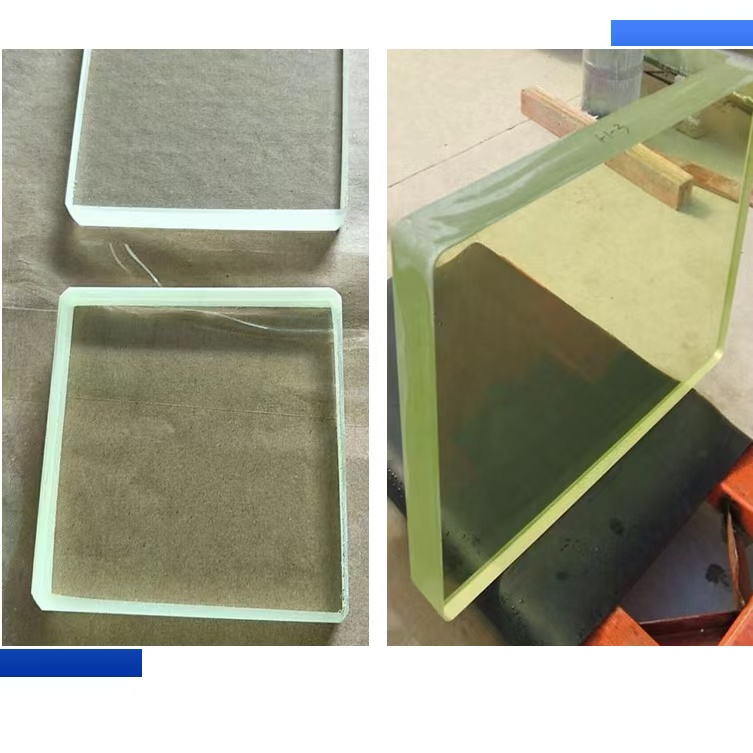

Product composition and characteristics

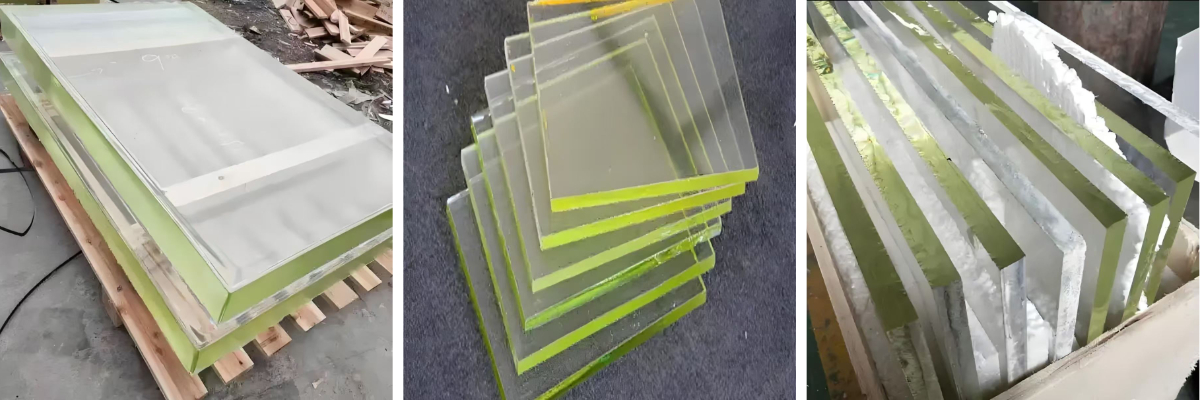

Radiation-proof lead glass uses high-purity silicon dioxide (SiO₂) as the base material, and is made by melting 20%-80% lead oxide (PbO) at high temperature. The density reaches 6.2-8.0 g/cm³ (about twice that of ordinary glass). Its core parameter lead equivalent (0.5-8.0mmPb) directly represents the radiation shielding effectiveness-for every increase of 1mmPb equivalent, the shielding rate of 120kV X-rays increases by more than 85%. The product also maintains excellent light transmittance (visible light transmittance ≥82%) and low distortion rate (<0.3%), with a surface hardness of Mohs 5.5 and impact strength in line with GB/T 9963 standards.

Core technical advantages

Precise protection

Supports customized lead equivalent (0.5/1.5/3.0/6.0mmPb, etc.), adapted to different radiation scenarios. For example:

Medical CT room: ≥2.5mmPb (shielding scattered X-rays)

Nuclear industry control room: ≥5.0mmPb (defense against gamma rays)

Environmental adaptability

Temperature range: -30℃~180℃ (no structural deformation)

Corrosion resistance: resistant to conventional disinfection such as 75% ethanol and 84 disinfectant

Anti-aging: UV coating prevents yellowing and has a service life of more than 15 years

Safe and environmentally friendly

Lead elements are stably sealed by chemical bonds, passed ROHS and ISO 14001 certification, and have no risk of heavy metal precipitation.

Installation and customization services

Structural form: flat/curved surface (maximum arc 150°), sandwich (explosion-proof), hollow (insulation type)

Dimensional accuracy: cutting tolerance ±0.5mm, maximum processable size 2000×3000mm

Edge treatment: edge grinding and polishing (EN 12150 certification), chamfer protection, metal edging reinforcement

This product has passed the dual certification of radiation protection (GBZ 130-2020) and building material safety (GB 6566), providing transparent protection solutions with high shielding, visibility and durability for medical, nuclear energy, industrial and other fields.