Radiation Shielding Glass

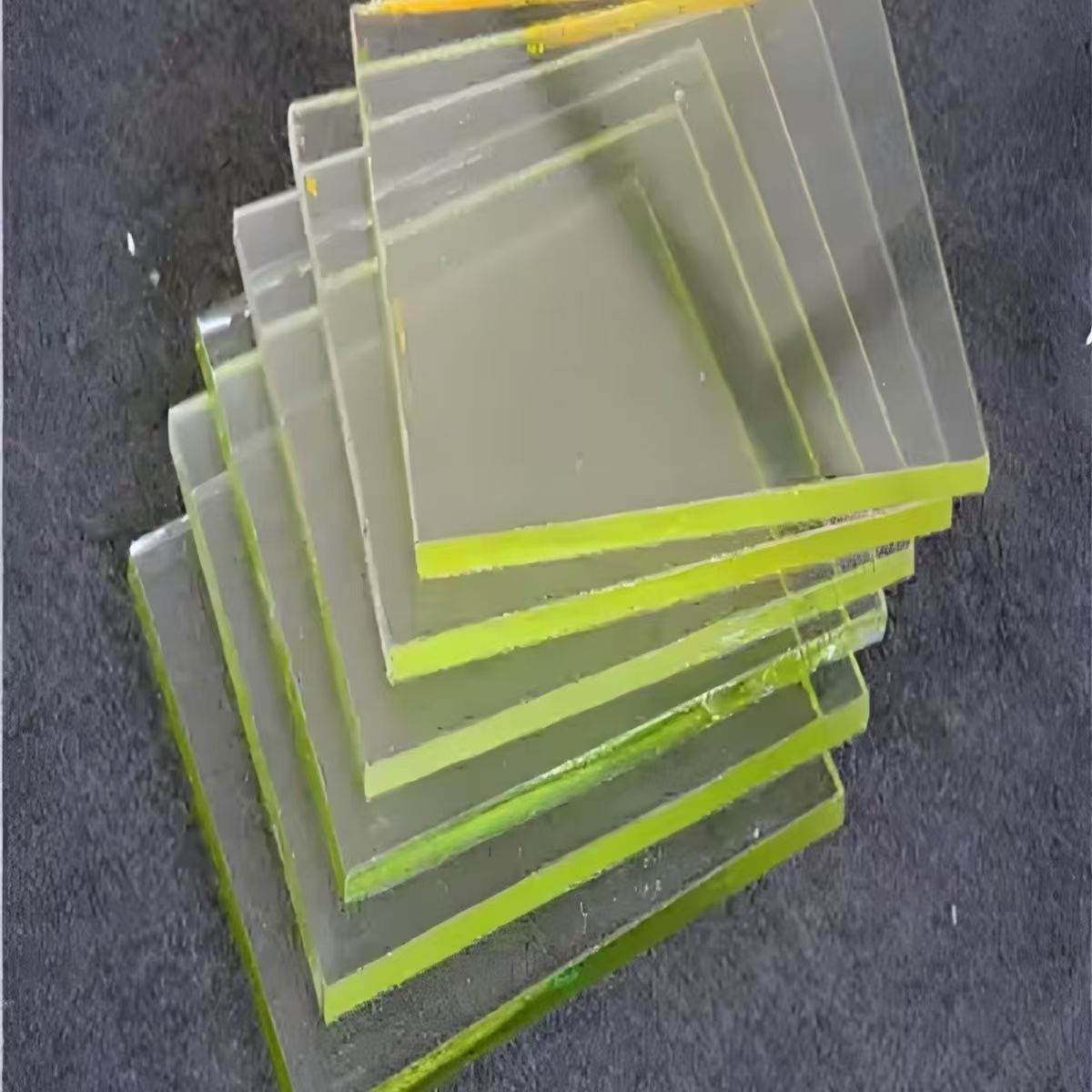

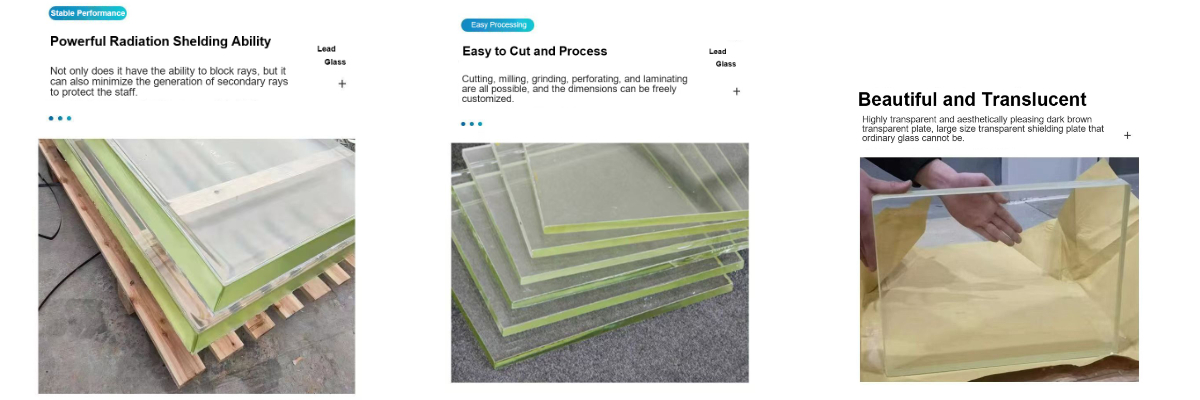

High-efficiency shielding: high lead content (density 6.2-8.0 g/cm³) strongly absorbs X/γ rays, lead equivalent 0.5-8.0mmPb can be customized freely;

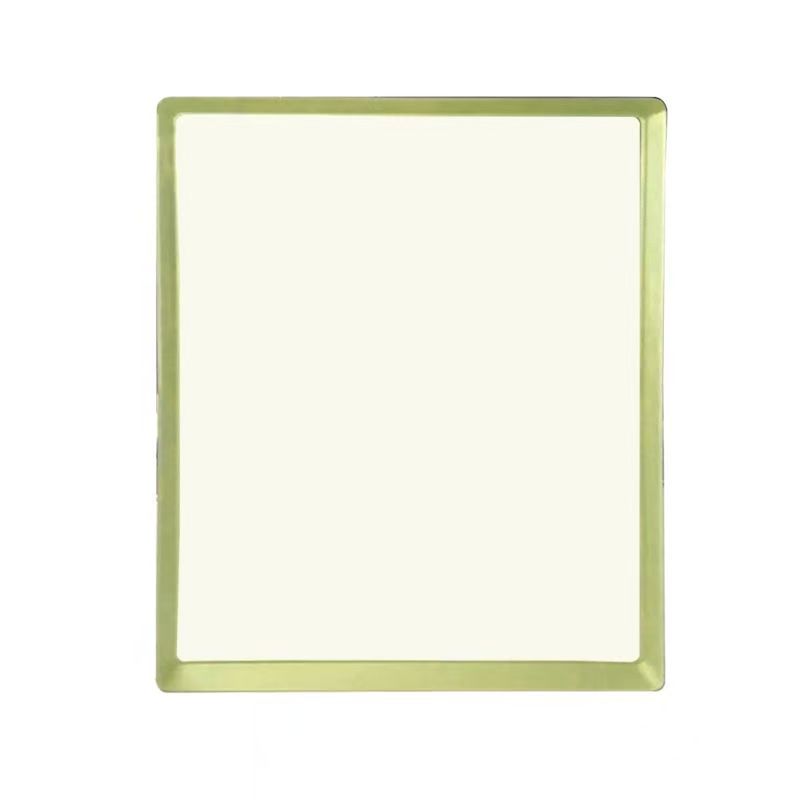

Transparent monitoring: light transmittance>80%, no visual distortion, and real-time observation of the radiation area;

Sturdy and durable: impact resistance, corrosion resistance, anti-aging, life span of more than 15 years;

Safety and environmental protection: lead elements are stably sealed without precipitation risk.

Irreplaceability: the only radiation shielding material that combines strong protection and high light transmittance, a rigid demand in the medical, nuclear industry, and security inspection fields.

Radiation shielding glass product technical specifications

Material structure

Using high-purity quartz sand as the matrix, 20%-80% lead oxide (PbO) is melted and doped to form a homogeneous glass body with a density of 6.2-8.0 g/cm³. The lead element is locked in the silicon-oxygen network in an ionic state to ensure no leakage risk (in compliance with ROHS/ISO 14001 standards).

Indicator | Parameter Range | Testing Standard |

Lead Equivalent | 0.5 - 8.0 mmPb (Customizable) | GBZ 130-2020 |

Light Transmittance | ≥82% (Visible Light Band) | ISO 9050 |

Distortion Rate | < 0.3% | DIN 52305 |

Hardness | Mohs 5.5 | GB/T 9963 |

Temperature Resistance | -30°C~180°C (No Performance Degradation) | ASTM C1036 |

Scenario-based protection scheme

1. Medical protection type

Applicable scenarios: CT room observation window (lead equivalent ≥ 2.5mmPb), interventional surgery screen

Features: thickness 15-25mm, light transmittance 85%+, support curved surface design (radian ≤ 120°)

2. Nuclear industry heavy

Applicable scenarios: nuclear reactor control room (lead equivalent ≥ 5.0mmPb), radioactive waste treatment

Features: thickness 30-50mm, composite explosion-proof sandwich structure, resistance to gamma ray irradiation > 10^7 Gy

3. Special for industrial flaw detection

Applicable scenarios: X-ray inspection cabin (lead equivalent 3.0-6.0mmPb), industrial CT equipment

Features: 20-40mm thickness, surface anti-scratch nano coating (hardness ≥7H)

Customization and certification

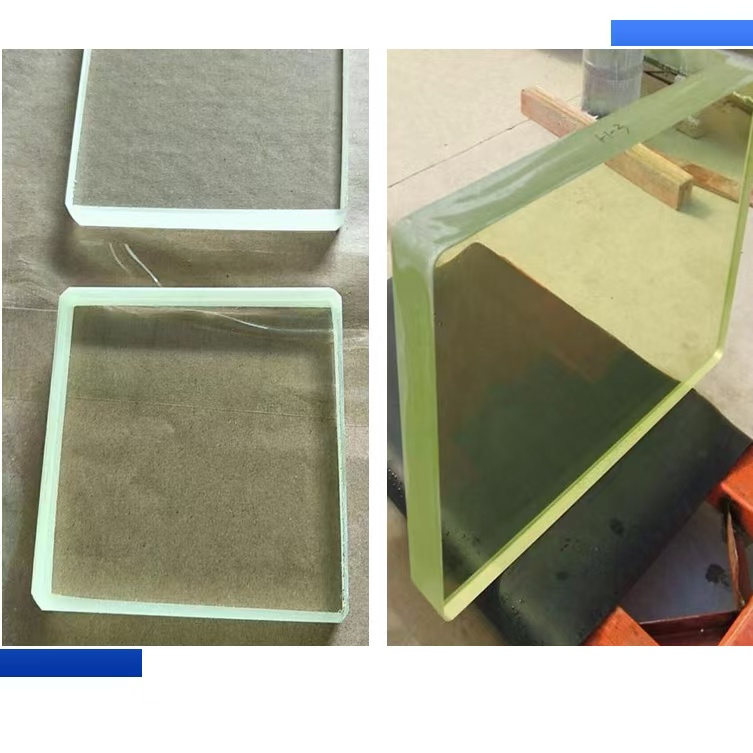

Dimension processing: maximum plate width 2000×3000mm (cutting tolerance ±0.5mm)

Edge treatment: diamond edge grinding (Ra≤0.1μm), stainless steel edge reinforcement

Certification system: CE (EN 61331-1), FDA 21 CFR 1020.40 and China Radiation Protection (GBZ 130-2020) certification

Technical breakthrough: using nano-bismuth oxide composite technology, the thickness is reduced by 12% at the same lead equivalent; anti-radiation yellowing life> 15 years (accelerated aging test ASTM G154).

Summary of core values

Precise protection: each 1mmPb equivalent can shield more than 85% of 120kV X-rays

Operation visualization: light transmittance is equivalent to ordinary float glass, no visual delay

Zero maintenance cost: alcohol/acid and alkali corrosion resistance, UV coating anti-aging

Safety redundancy: impact strength ≥8.5J/cm² (2 times higher than the national standard)